Looming deadlines of expiring turbine warranties have project owners taking stock of options and planning their next steps. Lender requirements, project lifespan, and maintenance concerns are just a few factors owners must consider. The good news is that there are more options available than ever before. Project owners usually consider a third-party warranty, an OEM’s…

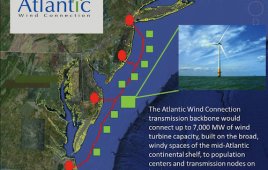

Major Transmission Project Planned for the Atlantic Coast

Google doesn’t mess around when it comes to investments. Their sponsorship in a transmission project that could cost billions of dollars stands as a major voucher for the wind industry. One of the greatest hurdles to the renewable-energy industry’s growth is the nation’s outdated transmission system. Without a beefed-up transmission backbone, offshore wind developers would…

The Right Turbine and Placement Produces 10x Power Increase

The power output of a wind farm of vertical-axis designs can be increased about tenfold simply by placing the turbines so they react with each other, say researchers at the California Institute of Technology led by John Dabiri, Caltech professor of aeronautics and bioengineering. In the summer of 2010, they conducted a field study at…

Bearing Manufacturer Unveils Plans for U.S. Wind Energy R&D Center

Massive, precision-engineered bearings and seals like those made by The Timken Company are central to wind power production. The largest of these rolling element bearings weighs more than five tons, with an ID of nearly 2 m. Such large bearings require sophisticated measuring and testing capabilities that replicate dynamic wind forces. For that purpose, Timken…

Turbine Doctors Revive a ‘Dead’ Vestas

It took two engineers from Availon North America a matter of hours to repair and bring on-line a Vestas V27 225-kW wind turbine that belongs to the Story County Medical Center in Nevada, Iowa. The turbine was commissioned at the end of 1994 but stopped working in April 2011 when the power supply for the…

New thinking in turbine design

A novel turbine design uses two rotors of equal diameter, one each at opposite ends of a nacelle, to capture wind at greater capacity factors than conventional designs can do, say developer Airgenesis LLC (airgenesiswind.com). The developer says the rotors, offset from each other by 60°, will be turning at low speeds of 2.5 to…

Variable speed hard-geared transmission may improve wind power efficiency 5 to 10%

A variable-ratio transmission that uses gears and chains, but no belts, has been introduced for licensing and production by inventor Gary Lee, CTO of VMT Technologies (www.theuniversaltransmission.com). The transmission works by expanding or reducing the diameter of a “moon gear” that drives the chain, thereby changing ratios. It does not rely on friction, which means…

Entrepreneur Proposes Wind-Turbine Gear Factory For Indiana

You might think the U.S. has lots of gear-making capacity, so why would a start-up envision a factory capable of more of the same? The answer lies in the size of the gears planned by Vela Gear Systems CEO Noel Davis. Gears required in the wind industry can be in excess of 6 ft in…

Improving Wind Turbine Design Through Advanced Simulation Techniques

Advancements in simulation technology continue to provide benefits to engineers in the field of wind power engineering. Windpower engineers now have the ability to simulate all aspects of the wind turbine; from detailed structural models of the blades that determine stresses and strains, to highly accurate aerodynamic models of the rotor that reflect its response…

Reducing Blade Repair Costs With Suspended Access Platforms

Wind turbine owners are faced with expensive choices when it comes to blade inspection and repair work. But there are alternatives. The case studies in this webinar will show how suspended platforms provide a stable, simple, modular approach to blade access. Hear our trainer and industry veteran tell how faster mobilization and smaller crew sizes…

Optical Fiber Applications for Wind Power Systems

In this webinar, you will learn some of the driving forces behind the evolution of wind power systems as well as the design challenges, specifically in the area of data communications. Solutions for high-reliability communications links using optical fiber technology will be presented. These solutions offer the galvanic isolation and electrical noise immunity required to…

Jack-up Vessels to Speed Offshore Wind Installations

The future of the world’s energy supplies is being decided to no small degree by offshore projects. Wind power offers its greatest potential at offshore facilities far from shipping routes and harbors. According to the European Wind Association, installed offshore output should increase tenfold in the next six years, reaching up to 15 GW. AWEA…

Contributors to Windpower Engineering July 2011

Marcy Offner, marketing manager for Composites One, has worked in the composites industry for 13 years. She has been instrumental developing the company’s Closed Mold Program and the launch of the Closed Mold Alliance, and supports the Composites One Wind Energy Team. Her industry training includes CCP Gel Coat School, Owens Corning Fiberglass School, and…

We’re in Campaign Mode Too

You have to admit that Congress has a lot on its plate right now with three wars and an economic mess, so expecting it to pass a national energy policy is a bit much. However, defining and financing such an enormous project should be the centerpiece of the next administration. At this time, both sides…

Life in The Supply Chain

McSwain Manufacturing, a division of Heraux Devtek in Cincinnati, Ohio, has been manufacturing power-generation parts for almost 30 years. In fact, it manufactured for GE Energy Power Systems even before the company purchased Enron’s wind division and entered the renewable energy industry. “Because they knew us as a trustworthy vendor, they approached us with a…

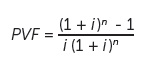

Improving a Project’s Rate of Return

When the Department of Energy enacted the national efficiency standard for distribution-class transformers up to 2,500 kVA in 2010 (72 CFR 58190), it excluded Generator Step-Up (GSU) units. This was unfortunate because the industry continues to construct wind-collector networks with sub-optimal GSU transformers which lead to lower overall collector efficiencies, lower kWh sales, and longer…

Planning Maintenance for Wind Turbine Blades

Like stately giants, utility wind turbines are appearing further afield and offshore. As designers tackle the job of building longer, heavier, higher performing turbine blades, wind-farm operators and owners are faced with a different challenge– keeping aging blades in optimum condition. Traditionally, less attention has been paid to the repair and upkeep of turbine blades…

Catastrophic Insurance for Wind Farms

Fraser McLachlan CEO GCube Insurance services, Inc. Newport Beach, California www.gcube-insurance.com The insurance market thought it had a bad 12 months with Australian fires and floods, plus the New Zealand Earthquake. Then Japan happened. The world is still reeling from the horrific damage and loss of life due to the March earthquake and tsunami. Governments,…

What Works in Aerospace Can Work in Wind

What do the areospace and wind industries have in common? They both depend on high-performance steel. Illinois-based QuesTek Innovations LLC (www.questek.com) has developed two types of gear steels that are already commercially available and in use in aerospace applications, but are suitable for wind-turbine gearboxes as well. Ferrium C61 and C64 are high-performance, double-vacuum-melted steels…

Better Bearings for Wind Turbine Reliability

Replacing failed bearings in wind-power equipment is no easy task. But after 20 years of concentrated effort, bearing manufacturers have devised designs that carry loads that fluctuate with wind gusts and work well in electric fields around generators. Viewers of this Webcast will hear presenters discuss the problems with bearing that shorten their life and…