Oliver Hirschfelder Global Wind Energy Director Capital Safety Red Wind. Minn. www.capitalsafety.us The World Wind Energy Association forecasts that the wind energy industry will employ one million people by 2012. This means wind power is becoming one of the largest sources of new electricity generation. As the market grows with more turbines on towers, so…

New Thinking In Wind-farm Development Cuts Costs and Time-to-energy

Nick Verrekia Director of Construction Gamesa Technology Corp. www.gamesa.com With careful planning and good teamwork, the time it takes to build a wind farm is shrinking, which is generating payoffs for developers, owners, and operators. Trimming time and costs is critical to continued wind farm development in an uncertain 2011. To illustrate the benefits of…

Financing a Wind Project

Financing a wind farm is one aspect of development that seems to be in constant flux. For a three-perspective view of the current financial landscape, join us for this webinar. Attorney Graham Noyes addresses the financing tools and incentives available to developers. Matt Mooney speaks on the financial instruments that made the Flatwater Wind project…

36-MW Battery to Stabilize 153-MW Wind Farm

A 36-MW storage system will soon be the world’s largest power-storage device linked to a wind farm. The $44 million battery and controls will go into operation Q3-2012, says North Carolina-based Duke Energy Corp. Xtreme Power manufactures dry-cell batteries for use with the variable delivery from wind farms and solar projects. The system will store…

Automating Wind-Power Forecasting

Paul Pilotte Technical marketing Manager Mathworks Natick, mass. www.mathworks.com Managing a wind-farm portfolio is a promising renewable energy business, but operators face risks and challenges. Wind farm operators selling power to wholesale electricity markets are looking for ways to maximize profits and reduce revenue uncertainty. To do so, they need software tools to analyze historical…

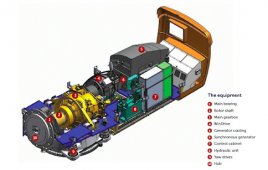

A Turbine that Supports the Grid

Demand is increasing for reliable turbines with network compatibility and quality power. One turbine manufacturer has incorporated these elements into a recent model. DeWind says it has built on its 2-MW series since 2002, and its latest 2-MW D9.2 is especially grid friendly. Just as its predecessor, the D8.2 introduced in 2006, the company says…

Detecting Ice on Wind-turbine Blades

Nick Harper Applications Manager Blade Sensing Systems Moog Inc. www.Moog.com Cold weather presents special problems for wind turbines. Inside the nacelle, low-viscosity lubricants keep the gearbox turning and enclosure seals to keep moisture and ice off electronic components. But outside the nacelle, things are different. Ice easily forms on turbine blades possibly adding hundreds…

May I see the Calibration Certificate for your Torque Wrench?

Many companies make the same mistake every year assuming their torque tools are accurate and in working order. They also assume factory torque charts are correct and a certified gauge ensures tool accuracy. It’s a hazardous assumption because calibrated power tools frequently are not performing as expected. Although there are other ways of establishing the…

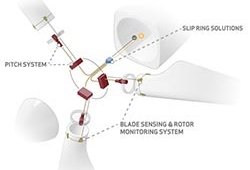

Wind Turbine Reliability – The Importance of Highly Reliable Pitch Control and Blade Sensing Systems

In this 40 minute webinar, learn how two common hazards can hamper a wind turbine’s production. Wind-turbine owners and operators may experience a significant reduction of generated power, reducing overall turbine efficiency, if they don’t take into account: Blade Icing Failed Slip Rings Issues Increased Reliability In this free webinar, we explore how Moog Blade…

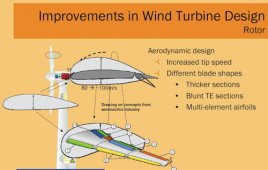

Is a 20-MW turbine possible? The Danes think so

The largest wind turbines have a capacity of 5 to 7 MW. After five years of research at the joint European project, UpWind, led by Risø National Laboratory for Sustainable Energy and the Technical University of Denmark, presented a first design basis for developing turbines of 20 MW. The project started five years ago with…

Wind Wakes May Spill Their Secrets

Wind turbine wakes produce invisible ripples that can affect the atmosphere and influence downstream units. Recent computer research into turbine spacing indicates about 15 rotor diameters are sufficient to dissipate wake effects and maintain the output of downwind machines. Because more detail is needed, researchers have launched a study to make the ripples visible to…

Europe’s Financing Lessons for U.S. Offshore Developers

Turbine manufacturer Areva Wind recently won a contract worth €400 million to supply 40, 5-MW turbines for the Borkum West II offshore wind farm in the North Sea near Germany. Under the agreement with Trianel, an association of German urban electric utilities and communities, Areva will provide the turbines, commissioning, and maintenance services. Foundations, transport,…

Rugged Encoders Ready for Harsh Wind Work

A manufacturer provides a line of reliable encoders to withstand harsh conditions and monitor them in the nacelle, blade, tower and foundation. The ultra-precise magnetic hollow-shaft encoders mount directly onto generator shafts up to 740-mm dia, and a 27-mm profile works well in limited-space environments. HDMag Encoders provide 17-bit absolute single-turn resolution, which delivers accurate…

Couplings Lock Gears, Discs, and more to Shafts

The big advantage for Ameriloc HLD (Hydraulic Locking Devices) is the short time it takes to install. With larger diameters, 530 mm, the HLD can be tensioned in a few minutes, compared to several hours required for another similar design. The hydraulic pump required for assembly can be a stationary unit, but use of a…

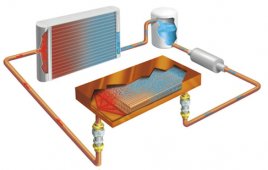

Two-phase Cooling for Wind Turbines

A novel precision-cooled rack is available for cooling critical wind turbine components. Parker’s Precision-Cooled Rack uses proven and patented two-phase evaporative cooling, which uses non-corrosive, non-conductive fluid, as it vaporizes and cools hot surfaces on contact. A small pump delivers enough coolant to the evaporator, usually a series of cold plates optimized to acquire heat…

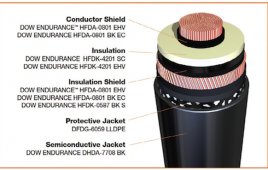

Materials ready for high voltage cables

A complete product line of materials is available to manufacture high voltage and extra-high voltage underground (UG) cables –from 66 kV to 500 kV. The DOW Endurance line, for HV (66 kV to 220 kV) consists of Endurance HFDK-4201 SC compounds for insulation, and Endurance HFDA-0801 BK EC for inner and outer semiconductive layers. For…

Remote Obstruction Lights Powered by Solar

A recent dc-powered lighting package for wind energy met towers uses a solar panel to recharge its batteries. The FTS 2301 dc-powered lighting package is an FAA-approved solar-powered obstruction lighting system. Key market requirements described the need for a compact, low-power unit powered by solar photovoltaic panels. The FTS 2301 addresses each need, and offers…

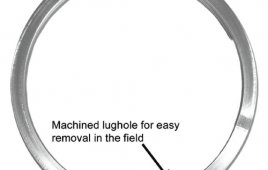

Retaining Rings for Rigorous Conditions

Rotor Clip says its Ventus spiral retaining ring series can withstand the rigors placed on wind turbine components by high wind speeds and other functional stresses. Thus, the component helps reduce costly downtime. A machined lug hole, designed to accommodate Rotor Clip’s V-Orbis tool, makes field installation easier than traditionally designed spiral rings, which cannot…

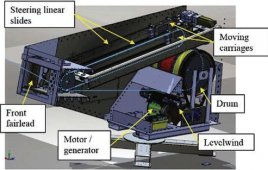

Clever Controls Let This Wing Pull Power Out of Wind

Many remote locations could benefit from a few extra kilowatts now and then. Inventor Matt Bennet has devised a way to provide extra energy in a trailer mounted airborne wind-energy device. In a nutshell, a large airfoil pulls two long tethers wrapped around a drum to drive a generator and store about 12 kW in…

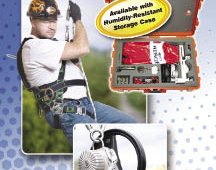

Rescue Assist Rated for Two Workers, Multiple Descents

A proper safety at height program includes the necessary steps for safe and quick rescue in an emergency. The SafEscape Elite RDD is the next generation global solution for rescue and descent that meets applicable safety standards throughout the world. It also lowers cost of ownership, enhances safety, and is easy to use. Companies operating…