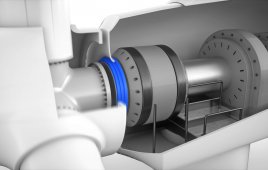

Hydraulics will probably provide the heavy-duty muscle in the nacelle. The systems there will be made of two-position valves, proportional valves for precise control, hoses, lubricants, fittings, and pumps.

Valve selection provides a good example of the complexity that comes in just selecting one component. Selecting a proportional hydraulic valve for pitch control is an important task. From a functional viewpoint, valves in turbine hydraulics are not required to do anything unusual. They simply control the flow of fluid to cylinders in response to sensor signals in a fairly straightforward closed-loop servo control circuit.

However, the valves are subject to temperature extremes, high and variable rotational and vibration loads, and long periods between maintenance. Servicing such valves requires the attention of specialized personnel.

In response to the wind industry’s need for more precise control, proportional valves are being equipped with an improved control interface featuring CANbus communication using the CANopen protocol. These electronic controls are packaged to industry IP67 environmental standards to meet the needs of the next generation of wind turbines.

Fittings and hoses should be considered critical components. They are key components in gearbox lubrication, typically an active system with constantly circulating fluids.

Hoses with class-zero leakage do not weep in extreme temperature variations or on cool down, so selecting them eliminates a potential source of fluid loss. Such hoses also promote a safer working environment inside the nacelle by keeping its floor drier and delivering extended service lives.

Premium hoses made with Teflon PTFE are resistant to bulging under pressure, making them a good choice for critical braking circuits. They are also chemically inert which is important in gearbox lubrication circuits.

Color coding these devices helps prevent assembly errors on shop floors, and potentially catastrophic failures on a system in service.

Filed Under: Hydraulics