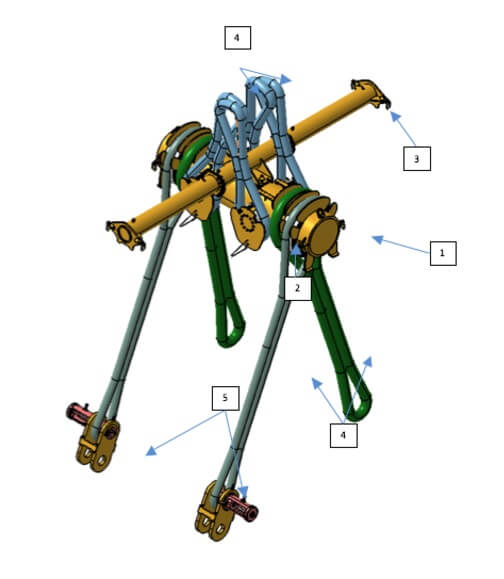

The numbers in the text refer to features on the lifting beam. Synthetic slings are in blue and green.

Wind turbine OEM Adwen needed a new nacelle-lifting toolkit and lifting equipment that was provided by Airpes. The company is in charge of the design and manufacture of this lifting equipment.

This tool consists of a main beam that is a steel tube (1) with two trunnions (2) attached to each side. Also, a beam attached perpendicular to the main beam has the function of helping guide the tool during hoisting maneuvers.

The hoisting is done with a synthetic set of slings (4) that connect both the tool and the nacelle of an AD8, an 8 MW offshore turbine. The main beam and trunnions attached to it can accept aluminum wedges (figure 2) that allow adjusting the tool’s longitudinal and transverse angle.

Additionally, two rear supports (5) with sliding pins allow fast hooking and release of the slings with the rear part of the AD8 nacelle.

The tool was designed for the full nacelle lift (after installing transmission tree or driveline) in the 600-ton ADWEN 8 MW generators.

The slings are made of a synthetic material that connects the tool and nacelle.

The main beam and trunnion can accept aluminum wedges which allow adjusting the tool’s longitudinal and transverse angle.

Also, two rear supports have sliding pins. This allows a fast hook and release of the slings with the rear part of the AD8 nacelle.

Filed Under: Construction