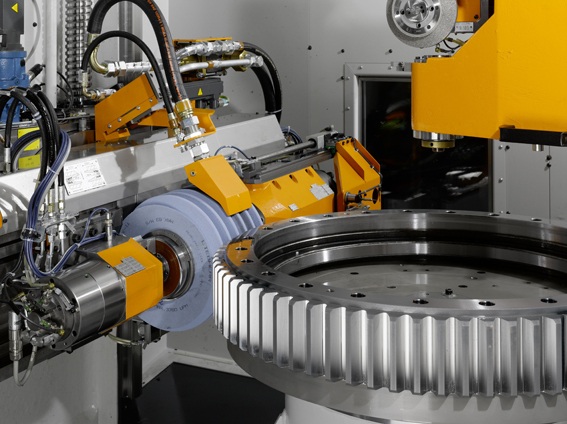

The new LCS 1200 gear grinding machine combines both generating- and profile-grinding into one machine, and now up to a workpiece diameter of 1200 mm.

German company Liebherr specializes in gear manufacturing processes, offering machines for large-module, high-volume gear grinding, and now in an extended platform range up to 1200 mm dia. The machine is well-suited for gear-grinding applications such as bull and output gears for wind power gearboxes.

The company says the LCS 1200 gear grinding machine combines both generating- and profile-grinding into one machine, and now up to a workpiece diameter of 1.200 mm. Gears up to module 12 can be economically processed with the generating grinding method. The machine has the capacity to produce noise-minimized gears in a two-flank grinding process exactly to a specified twist design. With profile grinding, gears up to module 22 or a profile height up to 50 mm can be ground. Tools with either electroplated cBN or dressable tools with corundum, sinter corundum, or cBN basis can be used for both grinding technologies. The high productivity machine can be supported by machine integrated automation, also designed and built by Liebherr in Kempten, Germany.

For the generating-grinding method, the maximum outside diameter of 320 mm on a grinding worm and the minimum usable diameter (which depends on the gear data), built in combination with the tool length of 230 mm, offers the longest tool life in this machine type class on the market, according to the manufacturer.

Liebherr LCS 1200 technical data

max. Workpiece-Ø: 1,200 mm

Axial Travel: 1,000 mm

max. Table Speed: 250 U/min

max. Tool-Ø: 320 mm

max. Tool Length: 230 mm

max. Tool Speed: 12,000 U/min

max. Modul (generating): 12 mm

max. Modul/Height (profile): 22/50 mm

Total Machine Weight 28,000 kg

Filed Under: Components