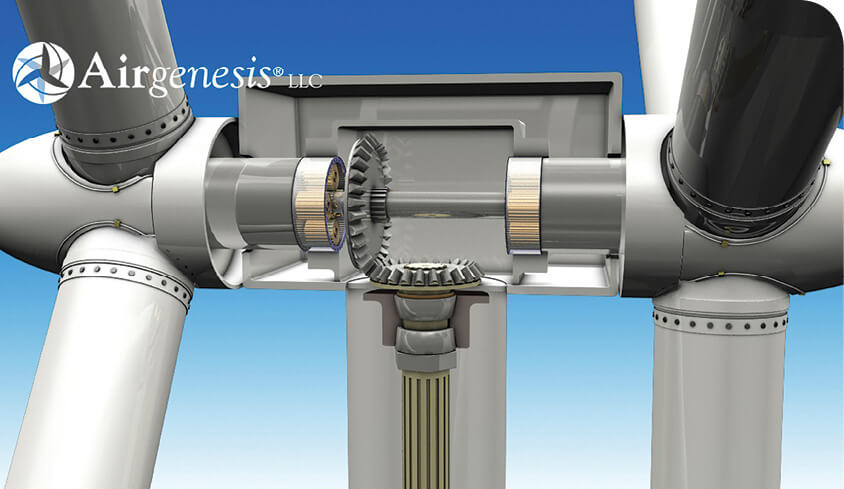

A CANADIAN INVESTMENT FIRM has stepped forward to fund the building of a 5-MW prototype of the two rotor Airgenesis design (airgenesiswind.com). The design was first covered here (tinyurl.com/airgenesis) in 2013. Briefly, the design uses two rotors on the same shaft rotating in the same direction. A right-angle drive in the nacelle turns a drive shaft to transmit power down tower to 11 MW of generators mounted at the base of the turbine. The arrangement opens up the possibility to create more power, takes weight off the tower, and provides for easier maintenance.

Airgenesis Senior Vice President Clayton Troxell says the 5-MW wind turbine, now the M2Y6Y 500 unit, will begin manufacturing later this year with construction to follow on Prince Edward Island, Canada, 2018, thanks to M2Miling Investments Limited (www.M2Miling.com).

The initial 5-MW M2Y6Y 500, designed by Airgenesis, uses two rotors turning in the same direction and mounted on a 78-m tall tower. Planetary gear sets increase the rotor speed while a right-angle drive will send power down-tower by a shaft. Generators at the base will come online as wind speed permits.

“M2Miling Investments will purchase buildings in October on the island,” said Troxell. “The turbine will include two rotors as in the original design, the center-tower drive shaft, and down-tower generators. The 5-MW design turned out to be a great model for the prototype. Once testing completes, plans are to construct full-sized, 5 to 11-MW units for wind farms around the world.”

M2Miling Investments Limited, Kingston, Ontario, Canada has licensed the technology for 10 years and will assist in building and testing of the prototype. “Their plans are to roll out manufacturing quickly after prototype testing. They have wind farms scattered around the world, and they want to implement the Airgenesis technology with others on the wind farms,” added Troxell.

The first order of business, he says, is altering the engineering for the M2Y6Y 500 tower, which involves minimizing the internal parts to handle lower stresses. This includes a clutch system that will engage several generators.

“The company will focus onshore with a 5-MW turbine on a 78-m tower, and eventually blades specific to the design. Their thinking is to develop the 11-MW model M2Y6Y1100 for higher wind onshore areas and offshore by 2020.

The investment company has projects and production facilities for Renewable Energy, research for Bio-Medicine by MariAlgaMed and does Vertical Gardening with IGES Canada.

“Generator sizes are not yet determined but probably start with 500 kW and several others that total 5 MW. They will be in the same pattern but arranged around a flywheel for a clutch system. That arrangement is still in flux,” said Troxell.

“The operation and maintenance companies of M2Miling will be happy with the safer control of all electrical components at ground level of the soon coming M2Y6Y 500”, said the CFO of M2Miling Investments Limited, Ulrich Lindner.

Filed Under: Construction, News, Turbines

Should be dual blade rotors verses tri blade. Save more weight and money. How is high cycle fatigue of downwind rotor avoided from blade and tower passing frequencies? I thought of this design thinking about rear end transaxels and also large vertical turbine pumps that can have several hundred feet of line shaft. How is tower distortion handled with line shaft alignment concerns? Is absence of more complex yaw system helpful?