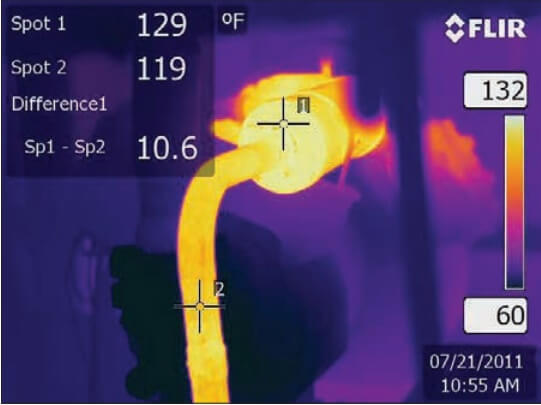

Editor’s note: Wind technicians who work around electrical equipment know that some things get hot without looking hot. An IR image of equipment can pinpoint the hot spots, and that is useful safety information. What surprised this editor is that recent cameras are relatively small and inexpensive.

Buying an infrared camera is a big commitment. Even though prices have fallen significantly over the past few years, you want to make sure that you’re getting the best value for your money and choosing the camera that will serve you well over the long term. For some, cost will be the driving force, while for others, key hardware or software features are more important.

Whatever camera you choose should, of course, offer quality and dependability, along with excellent technical support and service. There are lots of choices in thermal imagers, ranging from extremely affordable point-and-shoot models to highly specialized HD-level science and research cameras.

Finding the right fit for your needs can seem daunting. So along with the twelve things in this booklet to consider, you’ll find it helpful to define what you’re going to use the camera for and the work environments where you’ll be performing inspections.

Do your research on where thermal imaging technology is headed and the potential career and business opportunities on the horizon. In other words, think beyond your current needs to ensure you’ve done your best to future-proof your IR camera investment. If your specialty is weatherization, maybe all you need is a simple, lowercost point-and-shoot IR camera to spot missing insulation, poor weather stripping, and leaking windows.

If you’re an energy auditor, you may want a more advanced model that helps you generate professional, customized reports, or one that allows you to send images via a Wi-Fi mobile device to an agency that subsidizes improvements. Perhaps you need the benefit of higher resolution thermal imagery to help you build a strong marketing campaign for your services. Or you’re a restoration or HVAC contractor who needs a camera that links to moisture meter data to better-quantify the extent of damage or to track down condensation problems and coolant leaks. Predictive maintenance professionals also have a variety of needs that determine the kind of IR camera they should consider.

A utility troubleman may only require a simple point-and-shoot camera to do a safety check of energized equipment before performing repairs or for doing quick inspections of connections. Another member on his crew might need a high-resolution thermal imager to scan substations and power lines from a safe distance as well as gather detailed and accurate temperature measurements. Facility maintenance personnel and electricians might benefit from a camera that provides flexible ergonomics, allowing them to comfortably point the imager around tight corners, down behind motors, or straight up for equipment inspections overhead.

Register and read the rest here: http://goo.gl/QmaBjy

Filed Under: News