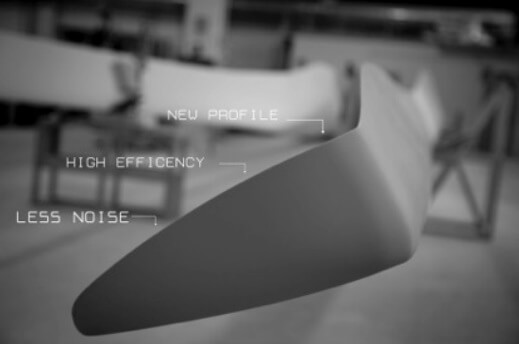

An official recent field test performed on a V47 turbine equipped with the new blade by eTa Blades confirms that re-blading (Replacing new wind turbine blades with new designs) as an efficient solution for aging wind-farms A recent field test, which has been officially performed on a historical Italian wind-farm owned by one of the most relevant Italian energy players and in collaboration with the top industry technical advisors, has shown that the adoption of the eTa4x blade – a specific blade designed and manufactured by eTa Blades – can deliver a net AEP increase of +20% when compared to the original Vestas V47 blades. What’s more, the new designs reduce loads on the turbine and produce no additional noise.

Re-blading becomes therefore an available tool or strategy to eliminate the symptoms of aging wind-farms. Giovanni Manni, eTa Blades’ CEO, says: “This result has been made possible through the adoption of the most advanced design and manufacturing techniques which include new aero-elastic concepts on innovative aero-dynamic profiles, linked to the adoption of new materials originally unavailable or not used for the manufacturing of wind blades.

The goal, says Manni, is to significantly enhance the cash flows of the assets, at the same time optimising the LCOE. eTa Blades, Italian wind blade designer and manufacturer, has introduced the concept of reblading in the wind industry to face the increasing need of reducing the impact of degradation on aging wind-farms and making marginal sites exploitable.

Re-blading is not just the possibility to purchase unavailable spare components, often out of production when it comes to old turbine models, but also the opportunity to increase the electrical output of the assets and reduce the OPEX for a measurable life-extension.

eTa Blades has conceived two possible business models to offer re-Blading: sale of components or long-term full-service. Test results and a case study are available at: http://www.etablades.com/re-blading/

Filed Under: Blades, News, O&M

Dear Robert –

I hope I’m not misunderstanding your point – in case, please advice. Our objective was to completely redesign the blade taking into account all the turbine constraints. It is therefore a new blade, not an upgraded copy of the previous one. The winglet is also our own design and its aim was twofold: to support the power curve enhancement and to reduce noise emission (the new blade is 1m longer than the original one). Hence, nor eTaBlades nor our customers have identified the possible commercial risks that you highlight. Interested in understanding better your point, if possible.

Regards,

Carlo

Hopefully eTa Blades looked at the numerous patents there are on wind turbine blades with winglets. If licenses aren’t in place, there could be an issue for prospective customers using this technology, which represents a commercial risk to the business model they’ve proposed here.