When compared to today’s direct drives, the HybridDrive offers a higher system energy

conversion efficiency, which in turn means a higher annual energy yield.

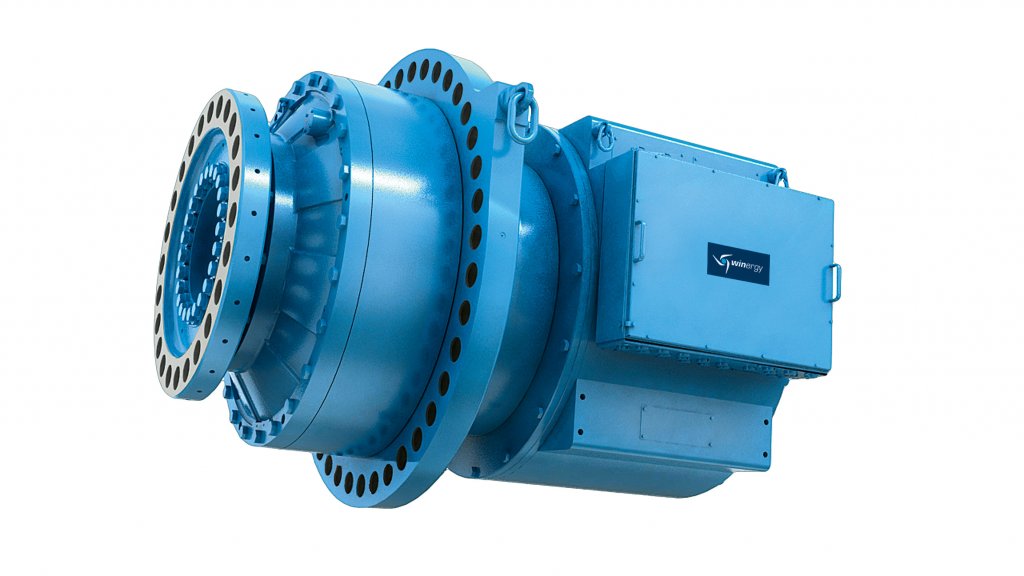

A gearbox manufacturer will show a fully tested hybrid drive, which will be connected to the grid by the end of this year. The cooperation between Winergy, W2E (Wind to Energy), and Fuhrlaender during the development of the FL3000 wind turbine is said to have shortened the overall development time for the turbine as well as the HybridDrive. The unit will be on display at the Husum Windenergy 2012 wind show in Germany in September.

The HybridDrive uses components that have been used in wind turbine applications for many years. These components have now been combined into one system.

Winergy invested in a new electrical system test bench to run system-specific test runs in parallel to development. The first step tested each individual component, and the second step verified the efficiency of the complete HybridDrive. Test results show a system energy conversion efficiency of more than 96%. Individual component tests even confirmed an energy conversion efficiency of about 98% for each component. The 34-ton HybridDrive sports a nominal torque of 2,550 kNm and a power rating of 3MW. The unit is for turbines with a 120-m rotor diameter. Reducing space and weight in the nacelle are key factors when selecting a wind turbine drive train. Another key feature is its lower dependence on permanent magnets and their volatile pricing. This improves the long-term planning options when it comes to purchasing materials.

The HybridDrive is a modular system, which allows replacing the permanent magnet generator with an electrically excited synchronous generator. This technical option is currently under development. Independent of generator preference, the technical basis allows building HybridDrives in a power range between 3 to 8 MW and therefore offers an attractive alternative for offshore applications.

Winergy

Filed Under: Components, Gearboxes, Generators, News