Engineers should be taking advantage of at least five trends forming in the control industry, says S. Arves Stolpe, a product manager with National Instruments, Austin, Texas (ni.com). Stolpe says that drivers for the trends come from ideas such as the notion that complexity translates to value. “The easy control problems have been solved, hence the tougher ones remain, so complexity will add value to a product,” says Stolpe. What’s more, technology advances in about nine month steps, he adds, so that if a product does not get to market in that period after the project start, it suffers the possibility of being second, and being first, says Stolpe, is better than being better. “In addition we see that most successful companies are not doing all development by themselves. Clients are working with us just as they are working with Intel and other large companies. Hence, their effective R&D budget is in the billions.”

Engineers should be taking advantage of at least five trends forming in the control industry, says S. Arves Stolpe, a product manager with National Instruments, Austin, Texas (ni.com). Stolpe says that drivers for the trends come from ideas such as the notion that complexity translates to value. “The easy control problems have been solved, hence the tougher ones remain, so complexity will add value to a product,” says Stolpe. What’s more, technology advances in about nine month steps, he adds, so that if a product does not get to market in that period after the project start, it suffers the possibility of being second, and being first, says Stolpe, is better than being better. “In addition we see that most successful companies are not doing all development by themselves. Clients are working with us just as they are working with Intel and other large companies. Hence, their effective R&D budget is in the billions.”

The key trend that allows the rest to unfold is software abstraction – using simple software to generate more complex control code. Abstraction is separating the important details from the unimportant. “The simpler code generating software lets design engineers get right to work.” Software abstraction also allows speeding up development, reusing code, making it easier to maintain, simulating its performance, and porting to different platforms.

The second trend is an increasing number of embedded processes. Look at Intel and the PC market, suggests Stolpe, and you see they have a single-digit market share when you consider all microprocessors. “It has taken 30 years to get to 1 billion connections , but only five years more to get to 15 billion. Embedded connected devices are a part of large network of machines. These will allow remote monitoring of more equipment, such as that in a nacelle.

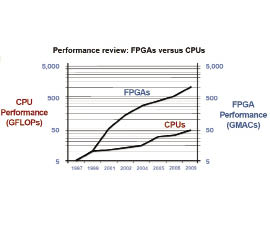

The third trend, reconfigurable hardware, refers in particular to FPGAs, field programmable gate arrays. These processor-like silicon chips work in many devices, such as cell phone and TVs. CPUs are less useful in many electronic gadgets because they need an operating system. ACISs, another processor possibility, are built for specific functions and could cost hundreds of thousands. FPGAs on the other hand, cost tens of dollars and are reprogrammable. So controllers in a nacelle can be reprogrammed for new functions from afar. In addition, FPGA performance far outpaces that of CPUs by a factor of 10. “LabView makes it easier than ever to program FPGAs,” he says, and their capability has been keeping pace with Moore’s law.

Trend four: Proliferation of sensors. Stolpe says expect to find sensors everywhere in part because they are getting cheaper and MEMS manufacturing techniques are making them smaller. “The old saying states a control application is only as good as what it measures; an event cannot be controlled if it cannot be measured. More powerful, less expensive sensors will allow using them in more places than previously possible.”

In addition, smart sensors can make control based decisions at the node, such as turn on devices or flip circuit breakers, or send back trend data. Expect to see more intelligence at the node. The spread of wireless technology is an accompanying trend that will let other controls staying in touch with the sensors.

The last trend to note is that of networking and synchronization, and connected devices. No machine will be an island. Expect to see more connected devices that synchronize their functions. Cars and their onboard computers are examples. These will lead to industrial protocols, more wireless connections, and timing and synchronization possibilities. Only the adoption rate is debatable says, Stolpe, WPE

Filed Under: Turbines