DNV GL Summer Project 2015 presentation to DNV GL’s top management and industry partners at Høvik on August 5. Back row, from left: Mr Kunikata (Japanese Ambassador to Norway), Remi Eriksen (DNV GL CEO), Kristoffer Bjerkelund, Bjørn K. Haugland (DNV GL Chief Sustainability Officer), Lars-Henrik Nysteen, Morten Aslesen, Katrine Storaker, Christian Carstensen, Adrian Mekki. Front row, and left: Kristina Dahlberg (DNV GL Employer Branding), Are Kaspersen (DNV GL Project Manager), Elsa Härdelin, Daniel Jakobsen, Eirin Fjellanger, Egil Gustafsson, Tadashi Uchihira, Karin Cederberg, Zhenying Wu

How can hydrogen help Japan transition to renewable energy? Students working for DNV GL this summer made the case for the floating installation ‘Jidai’ that produces hydrogen from seawater and wind energy.

Following the 2011 disaster at a nuclear plant in Fukushima, Japan reduced its reliance on nuclear energy and now depends heavily on expensive and imported energy, mainly deriving from finite sources. The country is now determined to become a “carbon-free” hydrogen society generated by wind, solar and hydroelectric sources by 2040, and this forms the background for the 2015 DNV GL summer project.

13 students were selected out of 500 applicants to come up with a solution for offshore production, storage and transportation of renewable hydrogen. Results from the project named Jidai could provide Japan with clean hydrogen, energy independence and a greener environment, as well as new job opportunities and more land-space.

Jidai: a new era

Hydrogen represents a significant untapped potential for renewable energy. Recent developments in fuel cell technology have promoted hydrogen as an attractive fuel for transportation and residential consumption.

“We have developed Jidai, a concept representing a new era for hydrogen consumption, as a way of harvesting offshore renewable resources and facilitating a complete value chain of clean energy,” says project manager and student Daniel Jakobsen, a 4th year student at NTNU.

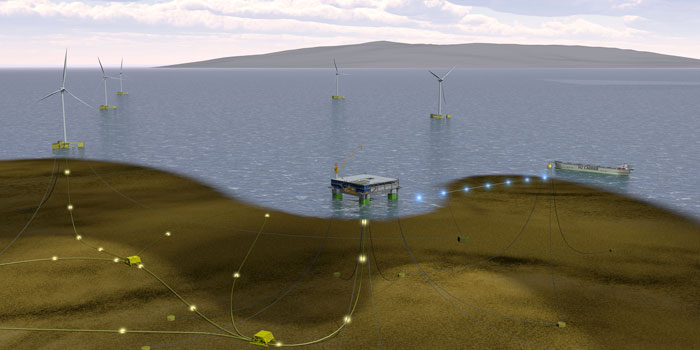

The concept uses floating offshore wind turbines to harvest hydrogen from purified seawater, using a process of electrolysis. The extracted hydrogen is compressed and stored, in readiness for transport by tanker to shore. The project is based on existing technology, and the students have estimated that the technology could be cost-efficient by 2030. Although perfect for the deep waters off Japan’s coastline, the system is easily adapted to a number of offshore destinations world-wide.

The project was presented to DNV GL’s top management and industry partners at Høvik on August 5. You can watch the students’ presentation here, and the animation explaining the concept here.

The Jidai concept uses floating offshore wind turbines to harvest hydrogen from purified seawater, using a process of electrolysis. Click the image to view a larger version. (Image credit: DNV GL)

Sparked industry interest

“The world’s energy mix has to shift,” said DNV GL Group President & CEO, Remi Eriksen, following the presentation. “To achieve that, we need to change the way we generate, transmit, distribute and use energy. This year’s student summer project has shown that use of offshore wind to produce hydrogen offshore is an attractive energy option for the future. The project also shows how technology innovation could create sustainable energy solutions at the same time as national ambitions on energy independence are achieved.”

DNV GL and the industry are interested in accelerating hydrogen energy technology to a commercial scale. Oil and gas companies have been especially looking to learn how decommissioned platforms can find new purpose as hydrogen production facilities.

“We need inspiring visions of the future to create new technologies and solutions,” says DNV GL Chief Sustainability Officer, Bjørn K. Haugland. “A green future presents us with plentiful opportunities for innovation and Jidai is an excellent example.”

The Jidai concept: Utilizing available technologies

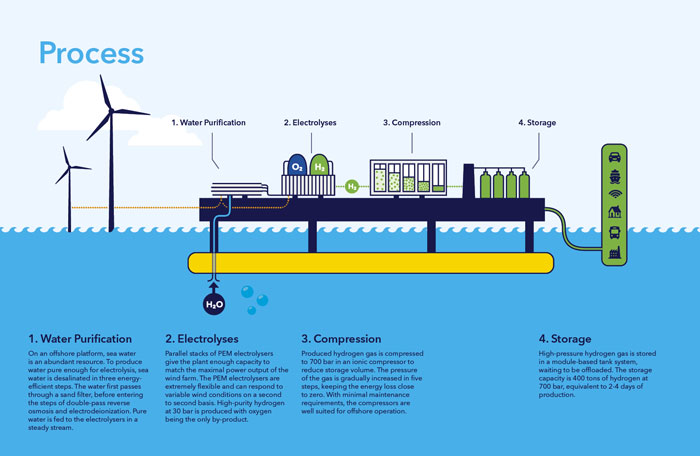

Jidai is a four-step process:

- Hydrogen production requires water with very high purity, and seawater is therefore desalinated in three energy-efficient steps.

- Multiple stacks of polymer exchange membrane (PEM) electrolysers produce high-purity hydrogen and oxygen from water. This gives the plant enough capacity to match the maximal power output of the wind farm. PEM electrolysis is at the heart of Jidai, and the electrolysers are compact and flexible, responding to intermittent power supply on a second to second basis.

- Hydrogen gas is compressed to 700 bar in an ionic compressor to reduce storage volume. The pressure of the gas is gradually increased in five steps, keeping the energy at loss close to zero.

- High-pressure hydrogen gas is stored in a module-based tank system. By using lightweight composite tanks, both weight and cost are reduced. The storage capacity is 400 tonnes of hydrogen at 700 bar, equivalent to three days of average production.

The four-step process of Jidai: water purification, electrolyses, compression, and storage. Click the image to view larger version. (Image credit: DNV GL)

All system components have been specifically chosen to withstand intermittent power supply from the wind turbines as well as frequent start-stop cycles without undue delay or wear. In addition, a combined battery and fuel cell backup system provide the power necessary for keeping critical equipment in operation when wind power is unavailable. As a result, the wind power can be stored and reactivated according to demand.

Even though the technologies in Jidai already exist, they need to be commercialized further before the concept can be applicable. According to project calculations, Jidai could be cost-efficient by 2030, well before Japan’s self-sufficiency due date.

Download the brochure here.

DNV GL Summer Project 2015

DNV GL has held an annual summer project since 2008. Around a dozen fourth year students work to solve a complex and relevant industry challenges. The project runs for seven weeks and is rounded off with a presentation to DNV GL, its management, and industry partners.

This year, the summer project had more than 500 applicants, and 13 highly-qualified students within engineering, nanotechnology, economics, and renewable energy were chosen to participate. The theme for this year’s project is ‘Offshore hydrogen production in Japan.’

DNV GL

www.dnvgl.com/

Filed Under: Featured, Innovators & influencers, News, Offshore wind, Projects

G’day

Not all that sure if relevant — I would have used wave power given that its a floating platform as a more constant power source to wind and can use pressure for desalination and movement for power generation for electrolysis and compression of product. Wave power and or tidal has more capacity in my view than wind due to a lower visual impact. just my option and as indicated — may not be relevant.

All in all a good rounded model.

Dear Jashua

I am a master student of NTNU and our EIT project is the same as what is mentioned here.

I have a question about the size of the electrolyzers and the link of student presentation doesn’t work can you send the correct link to me?

best regards

Seyedeh Fatemeh Hosseini