The Particle Pal Pro is a portable oil-analysis kit that provides ISO Cleanliness readings of virtually any gear oil.

Over 80% of mechanical failures in oil-lubricated machinery are attributable to particulate contamination. Wind turbines offer no exception.

The components lubricants are expected to protect are typically exposed to dust and dirt, given the harsh and variable conditions in which turbines are built. Oil contamination is inevitable at some point, which is why early detection is key to avoid potentially catastrophic machine failures.

An oil analysis assesses the quality of the oil and checks for contaminants. However, conventional methods have proven deficient in many ways. For example, taking a sample for laboratory analysis is time-consuming and inconvenient from the remote location of most wind farms. Laser counters used in particle counting are also less than ideal at recognizing air bubbles and eliminating them from the counts.

This presented a challenge: develop a mobile device that can efficiently take and effectively analyze an oil sample directly at a turbine site. This is precisely what Gemini’s Wind Innovation Challenge asked of its latest round of participants. The Innovation Challenge is a Dutch community-driven initiative and “proven concept of competition,” according to its developers, to solve the unique problems in the wind industry. (Learn more about the awards at offshorewindinnovators.nl)

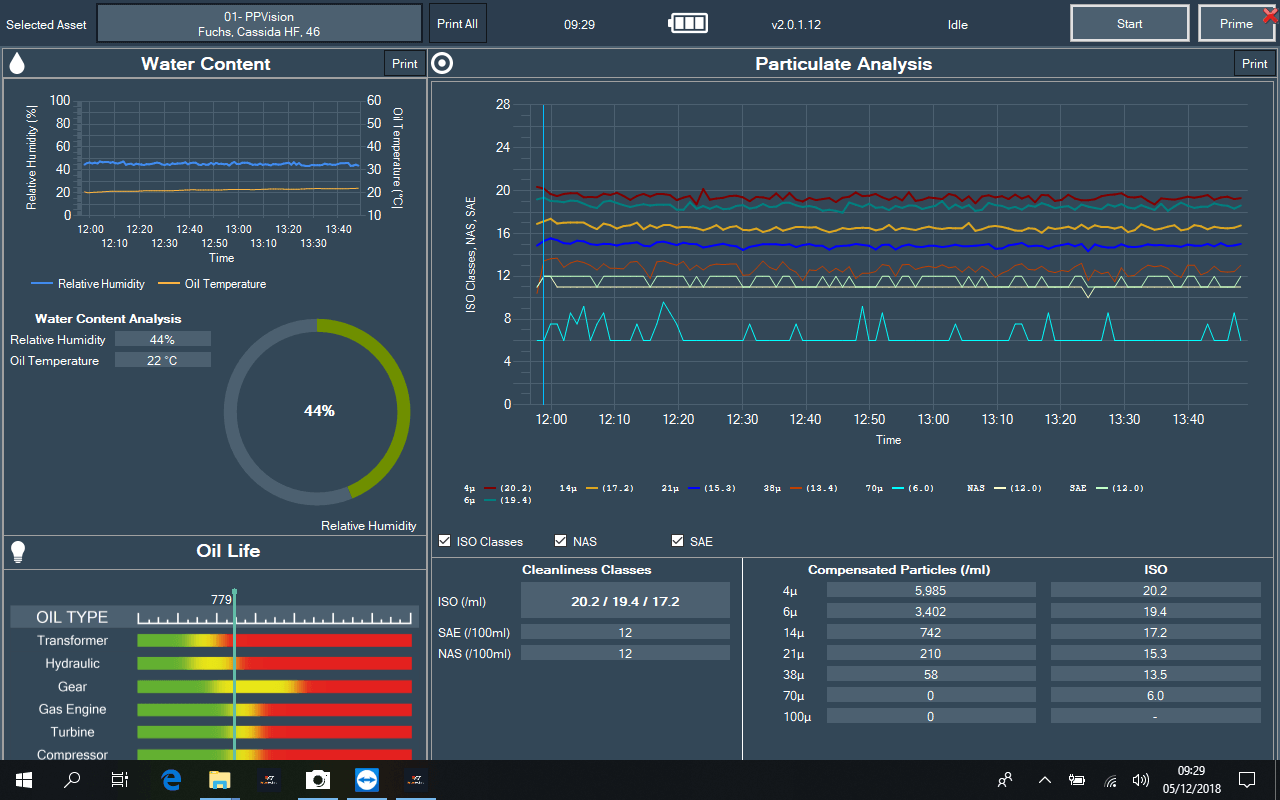

Meet the winner of the oil-analysis challenge: the Particle Pal Pro, which took home top place in the “On the Spot Oil Analysis” category. Particle Pal Pro is a new, tablet-based portable oil-analysis kit that provides wind techs almost immediate insight into the state of turbine gear oil.

This new digital-imaging counter, combined with water content and oil condition sensors, helps engineers quickly understand the current health and remaining life of their oils.

“We believe the product we’ve developed for the wind market will help engineers make informed choices on the spot rather than waiting weeks for lab reports,” explains Richard Price, Managing Director of Filtertechnik, a manufacturer and supplier of oil-filtration systems and co-creator of Particle Pal Pro. “The technology allows on-the-spot oil analysis no matter the viscosity of the oil or the quantity of air present.”

Filtertechnik collaborated with engineering specialists, Mel Systems, to develop a product that offers live readings of particulate counts and shape analysis. The latter lets users identify where dirt originated from for better O&M work. The Particle Pal Pro also provides users with a broader count spectrum and root-cause analysis. It does so by recognizing the shape of particles and categorizing them into “fatigue,” “sliding,” or “cutting wear” particles.

“The Wind Innovators Challenge was a huge catalyst in understanding and overcoming the unique obstacles in taking on the spot-oil analysis readings in the wind market,” says Price. “We moved quickly to adopt radical new digital imaging technology that eliminates air bubbles from ISO counts and provides live particulate root cause analysis.”

What’s more is the Particle Pal Pro assesses the oil’s water content and predicts its remaining life. In addition, the developers built a new pump that can handle highly viscous oils without issues. “This competition, which took place over a six-month period, majorly advanced our R&D efforts in wind energy,” he adds.

Filed Under: Lubricants, News, O&M

Thank you! This is very interesting and could be of great value to a wind site for periodic sampling.