Access to a wind site in difficult terrain can be a big problem for turbine installations. But Leitwind (leitwind.com), an Italian manufacturer of gearless wind turbines, says its direct drive 1.5-MW LTW77 1500 has a modular construction that simplifies on-site assembly with lighter loads. The manufacturer says their experience allows installing wind turbines in remote and difficult mountain areas—places where others companies may not go.

A technician in the rotor mount guides the crane operator during turbine assembly. The LTW77’s modular construction of its machine carrier, generator, tower, and hub allows easy transport and assembly. This means crews can install the turbine at sites with challenging terrain and limited access, such as this one in Bulgaria.

The LTW77’s generator is part of the load-bearing structure, which helps manage weight. The design is also said to eliminate costly external structures, such as transformer stations, by integrating all power electronics—transformer included—into the tower base rather than in the nacelle. This modular design helps lower transportation and installation costs.

The direct drive eliminates the gearbox giving the advantage of fewer moving parts and lower generator speeds. Fewer rotating parts means less friction, and less friction improves the turbine’s efficiency in slower winds. This makes the turbine suitable even in low-density wind power areas. The manufacturer adds that conventional generators take only a few months to go through the number of rotations the LTW77 will perform in its life.

Leitwind also offers ParkManager, which provides an interface to monitor and control wind farms, such as this one shown in Croatia.

Furthermore, a hollow rotor shaft allows safe and easy access to all serviceable generator parts. Technicians can quickly replace rotor components without having to dismantle the entire generator. Therefore, wear, operation, and maintenance costs are significantly reduced.

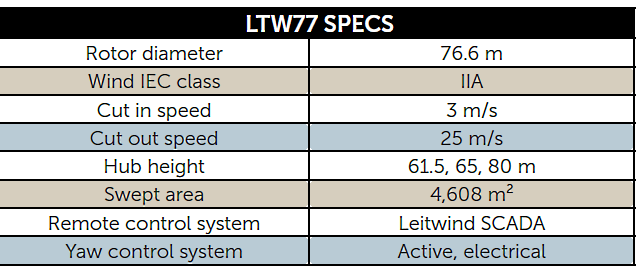

A multi-pole synchronous generator with permanent magnets makes the most out of the wind energy. Permanent magnets also improve yield by eliminating electrical excitation required by conventional generators. Also, a control system monitors turbine performance using variable rpm´s and pitch control to optimize production in partial and full-load ranges. Leitwind says this gives their turbines a huge advantage, especially in the partial-load range.

The turbine’s synchronous generator and frequency converter produces excellent grid compatibility, says the manufacturer. The LTW77’s converter is easily set to a wide range of connection requirements that meet the local grid codes of most any operator.

The grid side of the turbine’s frequency converter handles a wide reactive-power range and can support even weak and unstable grids. The turbine’s full power yield is fed through the Leitwind frequency converter so the generator can be taken off the grid completely when needed. Active and reactive power control and an ability to smoothly compensate sudden voltage drops are said to give the turbine grid connection characteristics similar to conventional power plants. WPE

Filed Under: Featured