Philip Totaro, Founder & CEO, Totaro & Associates

As the renewable-energy industry contemplates the future of technology, we have long contended that materials science will have the greatest impact on forthcoming cost reductions. With significant investments being made in R&D, we see a few classes of materials which deserve special attention, and potentially some additional investment.

Power conversion efficiency

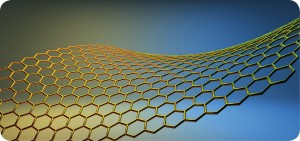

Graphene (pictured) and Germanene are two emerging synthetic materials which could improve system-level electrical conversion efficiency by 5 to 7% while reducing mass of the generation and electrical systems.

While most renewable energy systems operate at over 90% power conversion efficiency, there is still room for improvement. Synthetic materials look poised to make a dramatic impact.

Graphene and Germanene are two emerging synthetic materials which could improve system-level electrical conversion efficiency by 5 to 7% while reducing mass of the generation and electrical systems.

According to the University of Manchester, who first uncovered Graphene in 2004, “It is ultra-light, yet immensely tough. It is 200 times stronger than steel, but is incredibly flexible. It is fire resistant yet retains heat. It is a superb conductor, but not even helium can pass through it.”

Similarly, Germanene developed last year by a team of European researchers, can be used in a transistor that would remain at room temperature but increase output due to the power density of the material. This would mitigate the need for expensive and bulky cooling systems on electrical converters, generators / motors and potentially improve durability by up to 50% for certain electrical system components.

The processing technology for development and mass production of synthetic materials has significantly improved lately, but wide-scale commercial use of power electronics or energy storage products comprising these wonder-materials is still several years off.

In the interim, silicon carbide (SiC) based transistors are actively being investigated for use in converters, and are already commercialized for some solar applications. SiC based IGBTs offer much higher performance at the same temperature levels of conventional IGBTs. Nevertheless, scaling of the supply of SiC based IGBTs will be necessary to achieve a cost / benefit parity.

Aluminum could offer a better battery

The recent discovery of a fast charging aluminum-ion battery with a graphite cathode could potentially revolutionize small electronic devices, but some are hoping to extend this to MW scale storage or EV power packs as well. Unlike lithium-ion batteries, aluminum-ion is not prone to combustion resulting from overheating, and still offers comparable capacity to the best energy storage technology presently available. ‘Fast charging’ could mean almost as quick as a capacitor, but with better charge preservation to enable time shifting of power delivery.

The rising sun

For solar panel technology, capacity factor comparable to wind with equivalent per unit CapEx has been the recent industry struggle as solar strives for parity. Solar does have an advantage over wind in the ease of manufacturing scale, i.e. there is no need to change tooling regardless of project size, so production ramp up due to higher demand will see solar LCOE drop precipitously.

Look for multi-junction lattice matched (MJLM) cell technology to dominate in the future. A capacity factor increase of 12% up to ~43% since testing began in 1999, puts MJLM cells on par with wind. Their development trajectory suggests even more efficiency gains are in the works.

Silicon (Si) wafer and thin film technology have seen plateaus in performance enhancement with a capacity factor approximately half that of MJLM cells. That comes even with the recent LCOE reduction for Si wafer and thin film due to manufacturing scale resulting from increased global demand.

Organic compound cells are a current area of investigation as well, but they have a long way to go before being competitive.

REEs – Medium rare or over done

The desire to eliminate or mitigate rare earth material usage has gained attention in the past five years due to commodity price spikes and supply constraints. As such, multi-ferroics are materials which are capable of ferromagnetism and ferroelectricity concurrently. The ability to control this capability to change polarity at close to room temperature of offers a potential 3 – 5% LCOE impact with significantly lower mass and cost than conventional neodymium-iron-boron magnets.

This attractive class of materials is gaining traction for magnet replacement and / or generator flux enhancement, energy storage applications such as battery backup or in EVs as well as improving charge rate and capacity of ultra-capacitors.

Structural enhancements

Nanoparticles, essentially arrangements of carbon atoms in various configurations, have a multitude of applications from structural enhancement to energy efficiency. They are also currently being explored for their properties related to ice-phobic or erosion protection coatings, to lubricant additives as well as resurfacing agents. While the production of these nanoparticles has become more cost effective, the manufacturing process to apply them to surfaces consistently and uniformly still requires more development.

Metal-composite hybrid materials which combine lighter weight composites with the durability of aluminum, zinc, copper or steel can enable structural components with slightly more mass than carbon fibre but at significantly lower cost. Look for these to show up in wind turbine blades, nacelles as well as solar and wind electrical equipment enclosures.

We’re still a way’s off from 3D printed 80m long wind turbine blades, but expect to see more on this in a few years as sub-components manufactured with this technique are presently under evaluation.

All told, the materials revolution for renewables is set to have a profound impact. A keen eye will spot investment opportunities which will cultivate the next generation of commercially viable and cost competitive renewables.

Totaro & Associates

Totaro & Associates

Filed Under: News