It’s not hard to see the promise in the headline already. Just looks at what drones have done for the wind industry in the last couple years. In autonomous mode, a few can complete a blade inspection in about eight minutes, according to one developer. Damage and repair reports with photos are available shortly after that. And there is more to come, says DNV GL in a recent paper on the topic. The research and forecasting firm says AI, or artificial intelligence, will increasingly automate operations over the next several years in ways that cut O&M costs and improve production.

AI has been creeping into wind-farm operations in several ways over the last few years. As a result, most advances supported by artificial intelligence have been in resource forecasting, control, and predictive maintenance.

The consulting firm’s paper, “Making Renewables Smarter: The benefits, risks, and future of artificial intelligence in solar and wind,” suggests where AI such as machine learning will come into play in the renewables industry. The wind industry is an ideal application for AI because most turbines are outfitted with many sensors that generate mountains of data, and the industry requires complex decisions. Although the algorithms were developed decades ago, the recent advent of inexpensive cloud computing makes AI practical today.

The few wind industry areas ripe for AI include condition monitoring, robotics, inspections, certifications, and supply-chain optimization. The article How artificial intelligence will improve O&M in this issue shows one application of AI is well underway.

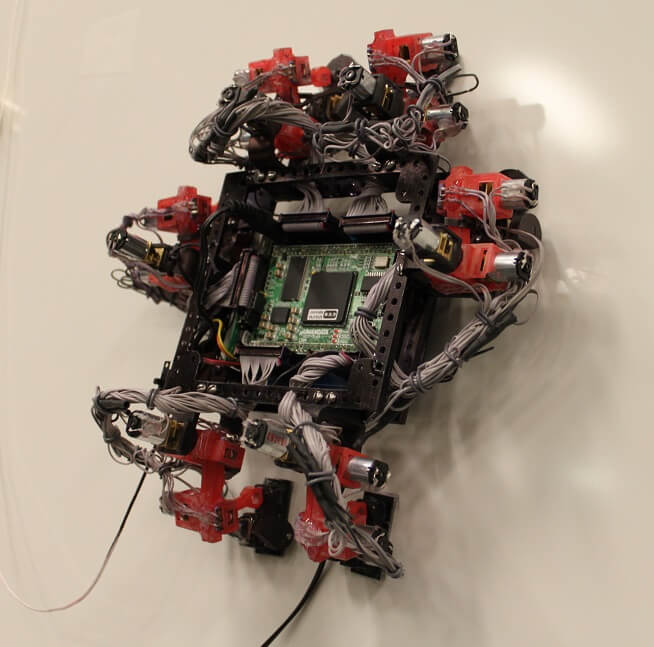

Wall crawling is a first step to an AI blade tech. Abigaille, a wall-crawling robot, was developed by Canada’s Simon Fraser University School of Engineering Science/MENRVA. The six-legged climbing robot is sufficiently dexterous and able to transition from vertical to horizontal surfaces. It clings to surfaces using a gecko-inspired dry adhesive technology.

Drones or flying robots have been the tip of the AI spear. The report suggests watching for robots that crawl, swim, and sail to perform remote offshore inspections and with eventual benefits of troubleshooting and maintenance of difficult jobs.

While the drones are good, a crawling robot might be better. Such a device could travel up and down and close to the surface of a blade, carrying microwave and ultrasonic transmitters and receivers to penetrate into the blade and pinpoint faults in its structure. Once an inspection robot is developed, the repair robot is close behind. Helical Robots have shown potential of its tower climbing unit for similar functions.

With regard to improving the supply chain, the authors of the paper foresee delivery of wind components by self-driving trucks and even the automation of some construction. The latter is not so farfetched. One solution to the automation of wind-farm construction was suggested by a UK firm in its Self-Erecting Nacelle System, SENSE. (tinyurl.com/sense-wpe).

“We expect the installation of more sensors, the increase in easier-to-use machine learning tools, and the continuous expansion of data monitoring, processing and analytics capabilities to create new operating efficiencies — and new and disruptive business models,” commented Lucy Craig, Director Technology and Innovation at DNV GL – Energy in a press release. AI systems are also likely to accelerate due diligence processes. Planning and analysis today might require many hours of human labor to collect and digest thousands of documents. AI may reduce the job considerably and with improved accuracy.

Stanford’s Ocean One is a hybrid between a humanoid robot and an underwater remotely operated vehicle. Photo: Frederic Osada and Teddy Seguin, DRASSM, Stanford.

Diving robots capable of performing undersea chores from inspections to repairs will further remove humans from hazardous conditions. For corrosion detection, autonomous underwater vehicles (AUVs) already carry hammers that tap underwater welds along with sensors and analysis capability. Simply automating the tasks robots are doing now will provide lots of ideas and challenges for applying artificial intelligence.

“AUVs could help in the construction and maintenance of offshore wind farms. One could imagine a situation where, after a severe storm, the onsite drones and AUVs are sent out to inspect the structures above and below the waterline and report on damage or critical issues that need attention,” said Craig.

Filed Under: O&M