The general construction industry has plenty of horror stories of how employees are injured. Bolting tasks should be fairly benign but they are not. Hydraulic and electrically powered equipment generate thousands of foot-pounds to tighten bolts. One stat says about 50% of construction injuries are to hands and fingers.

HTL Group says its hands-free bolting tools are easy to use, and with accessories, they significantly reduce the risk of hand-related injuries and dropped objects.

Although most bolting-equipment manufacturers and wind-farm safety managers constantly preach safety, it takes only a brief lapse of attention to put fingers where they should not be and suffer the painful consequences.

At least two companies that have recognized the hazard have also developed tools to keep construction worker’s hands and those of wind techs on O&M crews out of harm’s way.

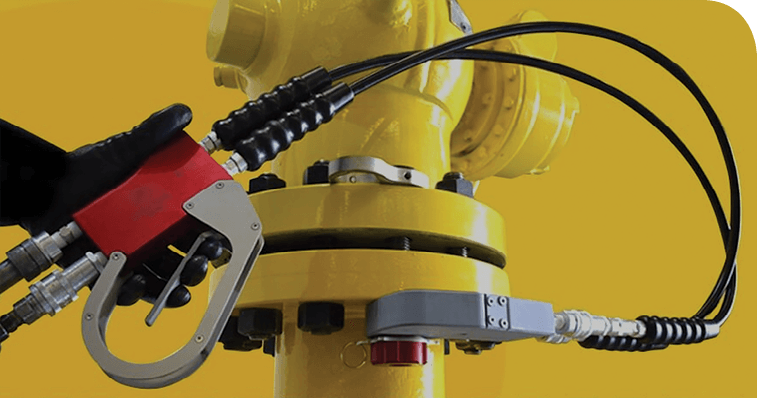

This first one, from UK based HTL Group, comes in a line of tools called Hands-Free Bolting. The company says the product range can help prevent common injuries when using bolting equipment in an array of industry sectors.

HTL adds that although the product has many mechanical applications, the devices are well suited to the controlled-bolting market due to the challenges faced when working on bolted joints on the ground or at height.

The Safe T lets a single person simultaneously operate the wrench and its hydraulic pump. The RSL series (2.5-in. square drive) has only three moving parts and tolerates up to 10,000-psi operating pressure. The square drive is interchangeable with hexagon cassettes.

The products are said to be easy to use while accessories also significantly reduce the risk of dropped objects and hand-related injuries. The patented range includes the No-Flog 2, a backing spanner that provides a safe, self-supporting, and hands-free tool to eliminate the need for a flogging spanner as a backing tool. Other tools in the Hands-Free line include a Back-Up Nut, Safety Valve, Tool Handle, and safety kits.

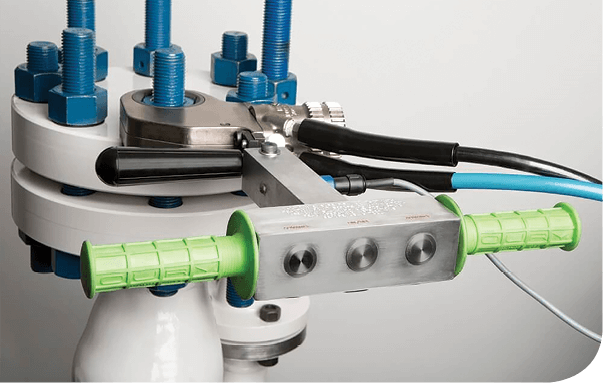

The second pinch-avoiding product comes in two RSL torque wrenches from Hydratight. The company says the wrenches are intended to increase safety and minimize the possibility of pinching during bolting operations.

The Safe T lets a single person simultaneously operate the wrench and its hydraulic pump. The tool houses three control buttons. Two main operation buttons must be pressed at the same time. This avoids the accidental hydraulic-pump activation by pushing only one button.

Should the operator release his or her hands, the torque wrench and hydraulic pump immediately cease to operate. Typically, one technician operates the torque wrench and another controls the hydraulic pump. With the Safe T, any chance of miscommunication in a noisy environment is almost eliminated thereby improving the safety of the operation.

“We’ve designed versions for use with electric and air pumps, and the low-profile design option will work with hex wrenches in tight spots,” said Chad Brooks at Hydratight. “The tools are made with a lightweight, durable aluminum housing and large diameter buttons for ease of use by a single technician. Models RSL20 and RSL30 (output torques of 18,843 and 28,002 lb-ft) have built-in loops for lifting straps. We’ve thoroughly tested the Safe T and it is ready for use,” he said.

Filed Under: Featured, Safety