Winter temperatures in Alaska can drop to -50°C, making power outages bad news. One way to prevent them is an emergency power source that feeds energy into the grid until back-up generation can come online. Battery backup is an economic and ecological alternative to ‘spinning reserve’ – gas turbines kept running in case of an emergency. In August 2010, the world’s largest battery was inaugurated in Fairbanks, Alaska. In addition to stabilizing the local grid, it will reduce power outages in the area by 65%. A consortium led by ABB supplied and installed the system.

A forklift adapted for installing, charging and watering the batteries, tracks a wire guidance system cut into the floor. The guidance system increases its speed while reducing the risk of colliding with the rack or batteries.

Golden Valley Electric Association (GVEA), a rural electric cooperative in Fairbanks, Alaska, serves 90,000 residents spread over 2,200 mi2. The local population needs a reliable supply of electricity because many residents live in remote areas and winter temperatures can fall as low as minus 50 °C. Back-up power therefore has to be available in the event of an outage.

Traditional reserve-power solutions require building and maintaining transmission and generation capacity well in excess of normal demand.

At the heart of the world’s most powerful storage battery system are a converter, designed and supplied by ABB, and nickelcadmium (Ni-Cd) batteries, developed by Saft. The converter turns the batteries’ dc power into ac power, for transmission over the GVEA grid. The batteries can produce up to 27 MW of power for 15 minutes, giving the utility enough time to get back-up generation on line. While the BESS is capable of producing up to 46 MW for a short time, the client’s primary need is for the system to cover the 15-minute period between sudden loss of generation and start-up of back-up generation.

Although the BESS is initially configured with four battery strings, it can expand to six strings to provide 40 MW for 15 minutes. The facility may accommodate up to eight battery strings, that would let GVEA boost output or prolong the useful life of the system beyond its planned 20 years.

The final spec required that the vendor provide a turnkey solution and guarantee for 20 years that the BESS could supply 40 MW for 15 minutes, with a 4 MW/min ramp-down after the 15-minute mark. The system must operate in all four quadrants (ie, the full power circle) and provide continuous, infinitely adjustable control of real and reactive power over the entire operating range. The BESS must also operate in an automatic mode because GVEA does not plan to man the facility.

The BESS can operate in seven modes:

- Var support: The BESS provides voltage support for the power system under steady-state and emergency operating conditions.

- Spinning reserve: In this mode, the BESS responds to remote generation trips in the Railbelt system. It is initiated at a system frequency of 59.8 Hz, with the BESS loading to full output at 59.4 Hz if system frequency continues to drop. Spinning reserve has the highest priority of all the modes and will interrupt any other mode the BESS is operating under.

- Power-system stabilizer, included to damp power-system oscillations.

- Automatic scheduling, used to provide instantaneous system support in the event of a breaker trip on either a transmission line or a local generator. The BESS has thirty independently triggered inputs, which will be tied remotely to the trip circuits of breakers.

- Scheduled load increase: This is initiated and terminated by SCADA and puts the BESS in a frequency and voltage-regulation mode to let it respond to the addition of large motor loads.

- Automatic generation control: In this mode the BESS is capable of operating by AGC, similar to that of rotating machinery.

- Charging: The SCADA dispatcher can control the MW rate at which the BESS will be charged and when charging is to start after a BESS discharge.

- The Alaskan BESS battery comprises 13,760 Saft SBH 920 performance rechargeable nickel-cadmium cells, arranged in four parallel strings to provide a nominal dc link of 5,000 V and a storage capacity of 3,680 Ah. The cells are built into 10-cell modules for mounting in a drive-in racking system. An aisle between the racks provides installation and service access for a swing-arm fork truck. The complete battery weighs some 1,300 tons and its building measures 120 x 26 m.

The initial battery configuration has four individual strings operating in parallel, but can be expanded to accommodate eight strings. Each string has 3,440 cells connected in series.

The battery features a pocket plate construction with thin, high-performance plates. This design allows attaining to the 20 to 25 year life without loss of the beneficial characteristics of Ni-Cd batteries. The type of cell used can deliver 80 % of its rated capacity in 20 minutes. Ni-Cd pocket plate cells can withstand repeated deep discharges with little effect on battery life.

The design’s several advantages:

- Compact arrangement: More rack depth can be used, minimizing the space taken up by aisles.

- Easy installation: 90 % of the connections are made in the factory; only the inter-module connections are made on site.

- Quick change-out: If there is a problem with an individual cell, the module containing that cell can be replaced by another complete module in less than 30 minutes.

- Minimum power losses: 99 % of the inter-cell connections are made with solid copper bars which minimizes power losses caused by flexible cable connections are therefore minimized.

- Spill isolation: The cells sit on a plastic grating, allowing spills to drain into the base of the module. The tray can hold the electrolyte content of all ten cells.

Golden Valley Electric Assn

www.gvea.com

Filed Under: Energy storage, News

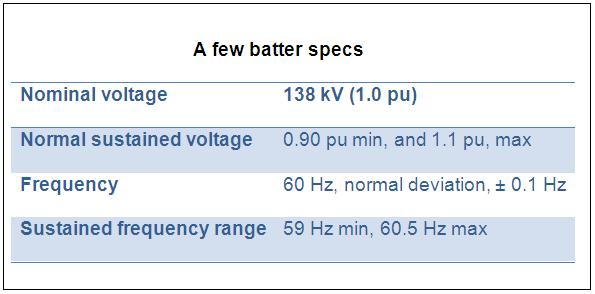

I am not surprised that you are using pocket plate technology. All the hype about lithium ion and like batteries sure makes me wonder, does anyone know what they are talking about. Pocket plate technology is the most rugged and most reliable on the planet. With 1300 ton that must be some install. About your battery chart and 138 Kv battery, are you serious. That is impossible. You would be lucky to have 600VDC for battery, when the voltage gets higher there are serious problems with dielectrics. In closing for power grid applications lead acid vented flooded cells and pocket plate nickel cadmium have proven they have stood the test of time. I am not saying the other plate technologies are not good, they just have not been around long enough and the will tell.

What is the actual operating voltage of each complete bank of batteries? If it is 138KV as as show in the chart above, I am assuming there must be a tremendous amout of circuit isolation insulation. Please note the misspelled word in your chart above. (Batter) Are the Ni- Cd batteries you are using the valve regulated type or flooded cell type? The Electric company I work for is not achieving a good life span on Valve Regulated batteries, certainly no where near the 20 to 25 year lifespan you are hoping for. They are used in our case for substation protection systems.

Thanks