Chris Shroyer / CEO / EdgeData

The concept of big data was once thought to be a route to improving wind turbine inspections. Somehow, more data would provide deeper insight to turbine conditions. Then came high-quality images and meta-data from aerial blade inspections.

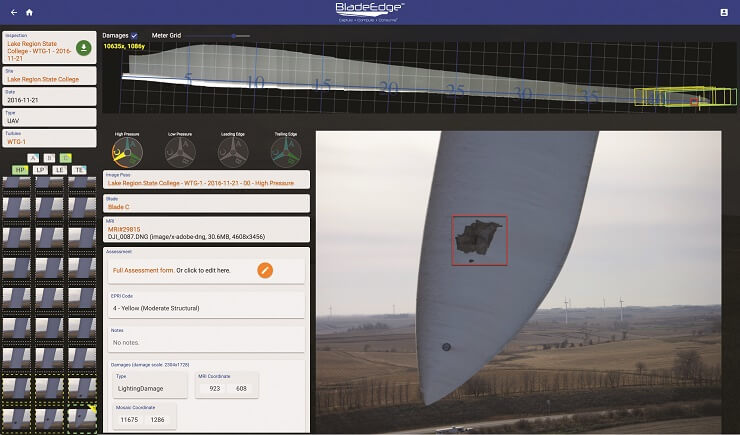

Instead of big data, actionable intelligence is the preferred result of unmanned aerial systems (UAS) or drone wind turbine inspections. More recent advances, such as “deep learning” technology lets computers recognizes damage, pinpointing exact areas that need attention. In addition, with time, the patent-pending analytic software can track trends in wear and damage, and help operators determine proactive plans to maximize infrastructure lifecycles and return on repair investments.

The three process pillars we have found most useful are Capture, Compute, and Consume. These and more have come from collaborating with wind farm owners and operators. By cultivating partnerships with industry leaders, we’re training the next generation of inspectors to capture data that provides actionable information.

Turbine inspections by drones or UAS are still new, but dedicated groups are forming standards for flight procedures. Earlier this year, we participated in developing flight operations procedures and processes for flying near wind infrastructures. Interested readers may find this useful: An Early Survey of Best Practices for the Use of Small Unmanned Aerial Systems by the Electric Utility Industry. It appeared in a publication from Oak Ridge National Lab’s publication. It’s here http://tinyurl.com/small-unmanned-aerial.

One program intended for use in the field, BladeEdge Capture Assistance Tool, ensures that every drone captures quality images. It also packages the images for processing by deep learning algorithms. This is a step toward automated flight assistance.

The future of UAS flights is being shaped by efforts of the faculty at North Dakota’s Lake Region State College (LRSC). Their Wind Technician Program now includes UAS curriculum in which students work towards remote pilot certification under FAA regulations Part 107. They’ll train on the capture assistance tool and best practices for flight procedures that we helped develop. The College’s student will graduate primed for wind industry jobs.

Compute

With LRSC training new wind technicians, a network of capable partners and technology bringing flight-assist software, we can focus on our core competencies: software, big data, and deep learning technology. Each time a UAS collects data, the patent-pending BladeEdge Analytics further trains the software to recognize damage and wear.

Not all flying conditions are created equal. In a perfect world, UAS inspections would be conducted on bright, sunny days. Of course, the weather doesn’t always cooperate. One useful software development is a tolerance for poor conditions, so operators will always leave the field with the data they need.

To store all the data collected, a 16,000-square-foot data center is being built at Grand Sky, a UAS Business and Aviation Park in Grand Forks, North Dakota. The highly secure facility will let us host an optimized environment for operations applications such as BladeEdge.

Consume

For the wind industry, this means operators will have access to better data and complete blade imaging. They’ll be able to make educated decisions for proactive maintenance and damage repair – maximizing energy output (AEP) while negating potential losses.

One output screen from EdgeData. Damage is identified and recorded along with other photos from the same turbine.

This method focuses on delivering cost-effective and scalable solutions through partnerships that serve the entire industry. Years of compiled data will allow making a longitudinal comparison of damages. Trends will show how blades degrade over time. When raw data is turned into actionable intelligence, there’s no telling what improvements will be made. What is sure, the industry will be improved through the programmatic use of currently available technologies.

Filed Under: Blades, News, O&M