This article comes from the network specialists at MOXA

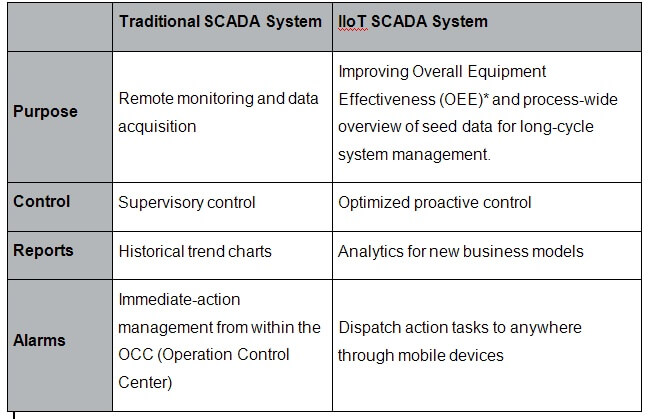

Modern SCADA systems are quickly adopting Industrial Internet of Things (IIoT) technologies, such as cloud services or pub/sub protocols, to collect more data from monitored systems. The fact that the amount of data involved is expanding at an ever-increasing rate means that today’s SCADA systems must manage thousands of times more data than traditional SCADA systems from a decade or two ago.

Smart data acquisition enhances big data integrity

For many years, “updating data by polling” has been the industry standard for SCADA communication between the server and clients. However, polling IIoT devices can result in the collection of tons of worthless data from thousands of sensors, leading to high data storage costs and time consuming data analyses. When sensors spit out data at a frequency much smaller than the polling interval, such as is the case when monitoring a machine’s ON/OFF status, “updating by exception” can reduce the amount of data storage needed and increase the efficiency of data analysis.

When used together, Moxa’s ioLogik 2500 series, MX-AOPC UA Server, and MX-AOPC UA Logger form a turnkey solution that provides real-time data acquisition, data buffering in local storage devices, and automatic data completeness after network failures. MX-AOPC UA Logger imports data from MX-AOPC UA Server into a database in real time. When the network fails and then recovers, the logger automatically retrieves data logs, with timestamp matching the duration of the disconnection, from the data buffers of specific ioLogik 2500 devices, and then pushes the supplementary data into the database.

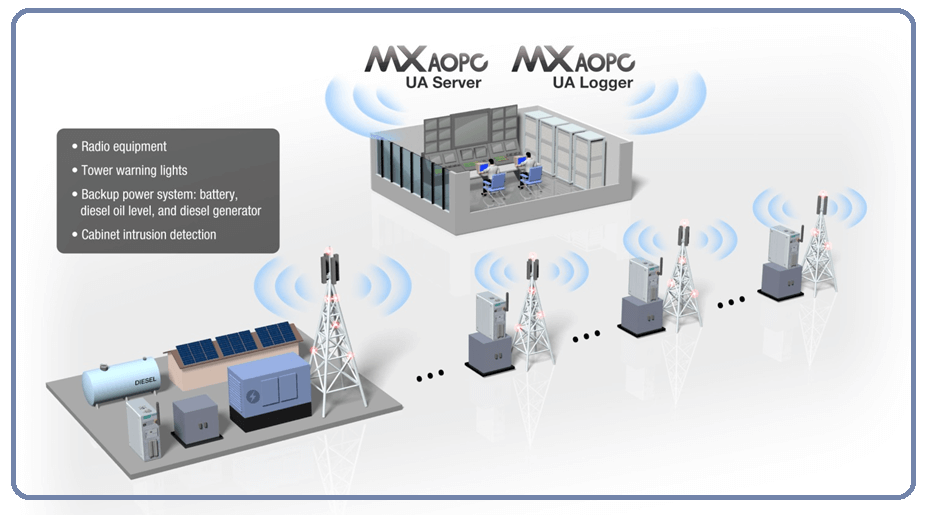

Case study: Radio station equipment monitoring

Many leading wireless carriers throughout the world are looking for cost-effective and efficient ways to manage remote, unmanned sites. The traditional method of sending maintenance personnel on regular, onsite visits is both inconvenient and costly. The obvious solution is to make it possible for maintenance engineers to remotely monitor and manage the unmanned sites efficiently, and proactively maintain and control their systems to prevent system downtime. In addition, since interruptions in wireless transmission are inevitable, during the disconnection period, data is saved to a local RTU. When the wireless network is back online, the data can be sent back to the central database automatically.

One solution provider uses Moxa’s ioLogik 2542-HSPA-T, MX-AOPC UA Server, and MX-AOPC UA Logger combined with their own SCADA software on a private cloud to provide a nationwide solution for radio station equipment monitoring. With this solution, engineers can monitor:

- radio equipment

- lighting on radio towers to ensure compliance with flight safety regulations

- the backup power system, including the battery, diesel oil level, and diesel generator

- cabinet intrusion detection indicators, equipment rooms, and areas that are off limits

In one application, about 100 unmanned sites are being monitored. One ioLogik 2542-HSPA-T is installed at each site. Each ioLogik monitors 12 analog inputs and updates the data to MX-AOPC UA Server using a percentage change strategy. The ioLogik also monitors 8 digital inputs and updates data to the server by exception, resulting in a dramatic reduction in the amount of data that needs to be transmitted. In addition, the amount of storage space required at the central site is greatly reduced. Whenever the connection between the ioLogik 2542-HSPA-T and MX-AOPC UA Server gets disconnected, it saves the data in its local storage drive for backup. Once the connection is back up and running, the MX-AOPC UA Logger automatically retrieves the data from the local storage drive and pushes the data to the central database.

Moxa’s ioLogik 2542-HSPA-T, MX-AOPC UA Server, and MX-AOPC UA Logger not only make it easy for the solution provider to transmit data to the database in real time, it provides complete data by automatically pushing supplementary data, stored locally during disconnection periods, to the central database. The system not only enhances data integrity, it also provides SCADA engineers with prompt and accurate data analysis.

For more information, download our white paper: How OPC UA Software Enhances Big Data Integrity for IIoT SCADA Systems.

A new solution is set to help the large number of substations fitted with legacy devices to migrate to Parallel Redundancy Protocol (PRP) and High-availability Seamless Redundancy (HSR) networks, without the interoperability issues currently giving the industry a hard time.

Get more mileage from substation’s legacy devices

A new solution is set to help the large number of substations fitted with legacy devices to migrate to Parallel Redundancy Protocol (PRP) and High-availability Seamless Redundancy (HSR) networks, without the interoperability issues currently giving the industry a hard time. For substations, this cost-effective solution not only brings a stay of execution for their many SANs (single attached nodes) and DANs (dual attached nodes), but also allows them to reap the benefits of a modern automated smart grid substation. In a nutshell, this new solution helps expand the lifespan of these legacy devices and defer replacement costs.

The search for a viable solution

Since the introduction of PRP/HSR-based networks as standards to address the need for reliable industrial communications, many substations have felt as if they were between a rock and hard place. Generally speaking, substations welcome PRP/HSR solutions that bring zero recovery time and versatile topology capabilities to their networks. In the same breath, however, substations want to move forward without getting rid of legacy devices that required substantial investment. Up to now, most solutions to migrate legacy devices to PRP/HSR-based networks have not been as viable and cost-effective as initially hoped for, since most legacy devices support Rapid Spanning Tree Protocol (RSTP), which cannot be read by PRP/HSR-based networks.

In IEC 61850 substation automation, a huge emphasis is placed on redundancy solutions that achieve “zero time” recovery, also known as “bumpless” recovery, with zero-packet loss as the main objective.

Migration to PRP/HSR networks

With the demand for high-availability and a very short switchover time, the recovery time of commonly used protocols such as RSTP is clearly not acceptable. Although ring coupling methods that integrate the RSTP and PRP/HSR protocols have been available for some time, most substations are still hesitant to embrace PRP/HSR-based networks due to numerous protocol interoperability issues.

A solution that fits all

Thanks to Moxa’s newly launched PT-7728-PTP PRP/HSR switch, which supports the IEC 62439-3 edition 3 standard, the interoperability issue is now a thing of the past. Products that support the IEC 62439-3 edition 3 standard must ensure that RSTP-supported IEDs can migrate to PRP/HSR networks seamlessly, without any protocol interoperability issues. In addition, as the world’s first rackmount modular PRP/HSR switch, the PT-7728-PTP provides users with greater setup flexibility.

Filed Under: Uncategorized