The importance of fastener coatings is becoming more apparent throughout the wind industry. Different coating chemistries have been used to improve corrosion protection, or lubricity, or both. However, increasing demands on field life, global legislation, and worldwide commonization continue to create challenges for many traditional coatings.

A thorough understanding of a fastener’s coating performance can ensure joint integrity, as well as improve field life and serviceability. Global acceptance and availability are also key considerations in choosing the right coating.

The Magni 565 coating allows formulating lubricants into the topcoat, usually eliminating the need for messy post-treatments. This non-electrolytically applied, zinc-and-aluminum-rich coating also eliminates concern of hydrogen embrittlement. The coating can be formulated in many colors. It also comes in several friction levels while providing good consistency across many bearing surfaces.

Advantages of fastener coatings

The importance of corrosion protection and lubricity in the wind industry differs from the building trades or the appliance industry. Varying demands have made it impossible to formulate one universal coating. A short list of what a coating should do includes:

• Improve appearance

• Add lubricity

• Protect against corrosion

Appearance

This is of lesser concern in most turbine joints, but it plays a key role when choosing a fastener coating in the building trades and appliance industry. Electroplated and electrocoated fasteners are predominant in these industries. Because such fasteners are often visible, it is essential to match colors and coat uniformly. Electroplated fasteners offer good uniformity and come in several different colors using different passivation systems, dyes, and a topcoat. Electrocoated fasteners also offer good uniformity but are typically available only in black.

Lubricity

Identifying a coating with the right frictional characteristics is probably the most crucial task. Erratic friction during assembly leads to either a loose joint or too much strain on the fastener. Either event can lead to a failed joint.

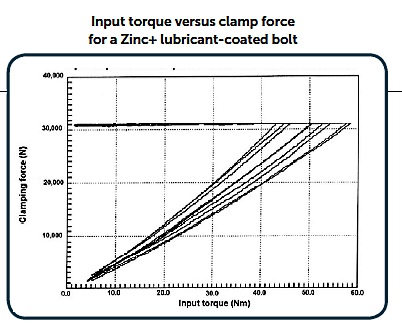

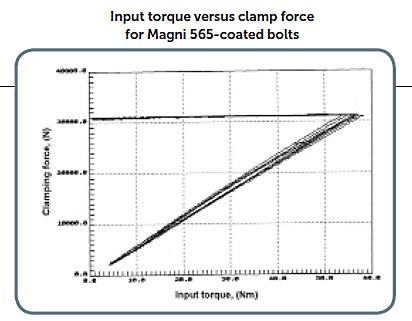

Two important components of lubricity are consistency and efficiency. Both are required to insure joint integrity and easy assembly. Proper lubricity assists the fasteners’ ability to efficiently reach its designed load at a prescribed torque. The torque-tension graphs (next page) demonstrate how properly integrated lubrication can improve joint consistency.

Some alloy platings also have improved lubricity but are typically more expensive than zinc plate or dip and spin coatings.

The three bolts on the left have been hot-dipped galvanized (HDG) and subjected to ASTM B117 for 500 hours. The three on the right, coated with Magni 565, have endured the same test but for 1,000 hours.

Corrosion protection

The harsh environments of wind farms have significantly increased demands on corrosion protection. The increasing demand on field life, as well as the use of aluminum and magnesium in other assemblies, emphasizes the importance of high-performance fastener finishes. Bimetallic assemblies often rely on coatings to reduce galvanic potential or insulate different materials in an effort to minimize corrosion rates. For this purpose, a duplex coating is becoming more prevalent.

Mechanics of corrosion protection

Although there is a myriad of finishes to choose from, there are only two basic types of corrosion protection: Barrier protection and sacrificial protection

Both protect the substrate from corrosion, but do so in distinctly different ways. To better explain these methods of protection, it is first important to review the corrosion mechanism. Iron corrodes by anodic, cathodic, and diffusion reactions. The reactions are described as:

Anodic reaction

Fe →Fe2++2e-

Cathodic reaction

4e- + 2H2O + O2 →4(OH–)

Diffusion reaction

2Fe2++ 4(OH–) → 2Fe(OH)2

Fe(OH)2 + O2 + H2O → Fe2O3 + H2O

Corrosion prevention inhibits the rate of these reactions, with either a barrier or sacrificial coating to the substrate.

Zinc-coated bolts show high deviation in the torque required to get several to a 30,000-N clamp load.

Barrier protection

One way to protect ferrous substrates is with a barrier coating. Here, the coating works as a barrier between a corrosive media and the substrate. Such coatings, often organic and polymeric in nature, come in a wide array of colors and can be applied many different ways, including by electrophoresis (electrocoat). These can be extremely effective, but performance diminishes if the barrier (coating) is damaged during assembly. These defects, macroscopic and microscopic, are inevitable and give the environment access to the substrate. Once this happens, oxidation of iron, along with the cathodic reduction of dissolved oxygen, attributes to the generation of OH¯ (alkalinity). Generated alkalinity can react with the coating causing it to dis-bond or delaminate from the metal interface, ultimately causing coating failures.

Barrier protection works best when coating defects are kept to a minimum. Excessive coating damage diminishes the corrosion protection proportionally and leads to premature failures. Therefore, material handling is critical when this technology is used.

Magni 565 coated bolts provide better uniformity in the torque needed to produces a 30,000-N clamp load.

Sacrificial protection

Another corrosion protection option applies a sacrificial coating. These include electroplating-galvanizing, Hot Dip Galvanizing (HDG), along with inorganic-organic duplex coatings. Although the application method for sacrificial coatings can vary significantly, the protection mechanism is similar.

Sacrificial corrosion occurs when two dissimilar metals come in contact. The more active of the two metals in the cell becomes a sacrificial anode and cathodically protects the other. To protect steel fasteners from corrosion, they are often coated with metals of higher reactivity. Zinc-rich coatings, whether electroplated, galvanized, or non-electrolytically applied, offer cathodic protection for steel fasteners by letting the coating “sacrifice” itself in place of the ferrous fastener. This technology relies on the coating to preferentially corrode.

Sacrificial coatings are affected less by coating defects than barrier coatings. The coating, which contains a more reactive metal, still provides cathodic protection around small voids and defects. However, excessive material handling can diminish the performance of this technology as well.

Understanding how these two systems provide corrosion protection makes it clear why duplex systems, such as Magni 565, can offer high performance to conventional galvanizing. The topcoat’s resistance of a corrosive media’s coming in contact with a sacrificial coating delays the corrosion mechanism. In addition, these topcoats can be formulated to provide specific frictional characteristics. WPE

By: Edward Koneczny, Windpower Market Manager, The Magni Group, Inc, www.themagnigroup.com

By: Edward Koneczny, Windpower Market Manager, The Magni Group, Inc, www.themagnigroup.com

Filed Under: Components