Robert Carlisle / President / Concrete Fastening Systems

It is often necessary to fasten cables, wires, junction boxes, and monitoring instruments to the inside and outside of concrete walls. The fasteners used for holding these categories of static loads come in a variety of types and sizes. To select the most effective fastener for securing wind-turbine equipment to concrete, it is important to consider these several conditions.

Rust resistance

An important question to answer before selecting a fastener relates to exposure: Will the fastener be exposed to rain and moisture or will it be protected from the elements inside a wind tower? The answer matters because of a fastener’s material composition.

For indoor or dry applications, standard zinc-plated carbon steel is sufficient. However, for outdoor, wet applications, stainless steel makes a better choice for durability. Most concrete fasteners are not manufactured in stainless steel, so its selection narrows to a few fastener models.

Load requirements

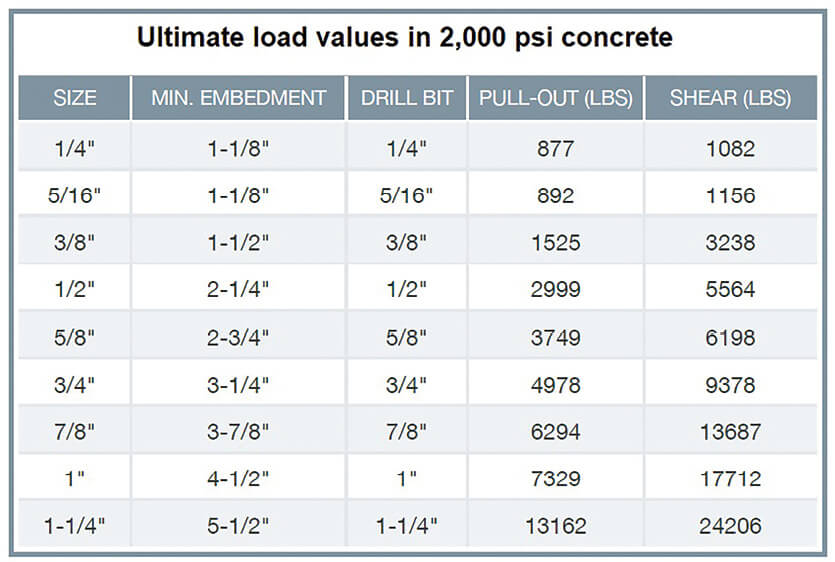

When considering load requirements for concrete fasteners, account for the weight of each item and how many fasteners the load requires. A table of loads is available for every concrete fastener, which describes the average values of pull out and shear for each diameter at the minimum embedment depth.

Load tables provide general guidance and are not a guarantee of accuracy. However, taking the same diameter of all the concrete fasteners and embedding each into the same concrete at the same depth will produce similar holding values.

Embedment depth

To install a concrete fastener, each must be placed and expanded in concrete to a certain depth to obtain minimum holding values. When concrete is used in tower construction, it is important to consider the placement of rebar and particularly in precast panels.

• If rebar is too close to the surface, it may affect the placement or size of the selected concrete fastener.

• Also, as selection diameter increases, so must the minimum embedment depth. For example, a 1/4-in. concrete fastener’s minimum embedment is 1 to 1-1/8 in. while a 3/4-in. anchor can have a minimum embedment of be 3-1/4 in.

Spacing

There are two spacing requirements to consider when selecting concrete fasteners: spacing between anchors, and spacing from an unsupported edge of the concrete.

• Expansion concrete anchors exert an outward or radial force. When this force overlaps with another anchor, it decreases the holding values of both fasteners.

• If installed too close to an unsupported concrete edge, concrete anchors may depreciate the force and lower the holding values. This means holding forces could approach zero or blow-out the concrete when the anchor is expanded.

A rule-of-thumb in the concrete-fastener industry is that the minimum spacing should be 10 diameters from each anchor, and measured center to center. The spacing from an unsupported edge should be at least five-anchor diameters.

Here is a summary of concrete fasteners useful for wind turbines

• Wedge anchors provide the widest range of concrete fasteners, from 1/4 to 1-1/4-in. and are manufactured in zinc-plated, 304 stainless steel, and 316 stainless steel.

• Wedge anchors are packaged complete with nuts and washers ready to install. Hole size is equal to the anchor size.

• Drop-in anchors are internally threaded concrete anchors and manufactured from carbon steel and zinc-plated. Versions in 304 and 316 stainless steel are also available.

• Tapcon screws are concrete fasteners that must be inserted into a pilot or predrilled. The hole tolerance is critical, 3/16-in. screw requires a 5/32-in. hole and the ¼-in. screw requires a 3/16-in. hole.

The pull-out and shear values shown, for a Confast Wedge Anchor are average ultimate values and provide a guide, not a guarantee. A safety factor of 4:1 or 25% is generally accepted as a safe working load. Reference should be made to applicable codes for the specific working ratio. Psi values refer to a compressive strength of concrete using standard test cylinders of six-in. dia. and 12-in. height. For each fastener design, the company provides a table of related dimensions and load values.

Filed Under: Uncategorized

Interesting article. So lif I have to secure a floor safe having a 5 inch base bottom with a 1/2 inch concrete screw i should use a 8 inch screw that should slightly exceed minimum embeddement need. Thought of using a 1/2 ‘wedge anchor too of 8 inches but should I need to move then an embedded wedge anchor is nonremoval where a screw anchor likely removable. Size drill bit u should use for a 1/2 screw is what 7/16?