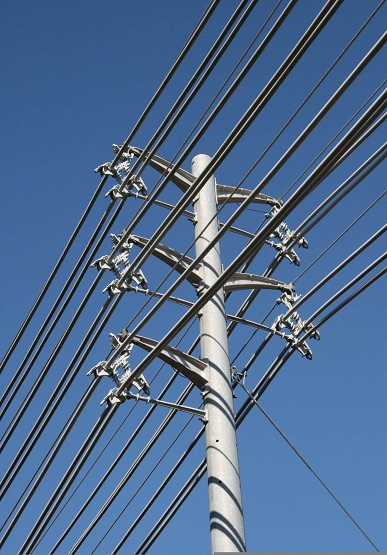

Growing communities need more electrical power and usually more electric lines strung conveniently

Hendrix Spacer-Cable systems feature a compact configuration and reduced requirements for clearance which means multiple circuits (lines) can be installed on a single pole.

overhead on poles. When a conventional pole carries its max number of lines, the local electrical company has several options. The experience of a small electrical cooperative is useful in understanding the general transmission problems in a growing community, and a few solutions.

The problems

Fort Loudoun Electric Cooperative (FLEC) faced the challenge of keeping up with the growth in its area. According to Chad Kirkpatrick, VP of Operations and Engineering, the mountainous Tennessee geography and limited rights-of-way required looking for alternatives to traditional open-wire structures, especially at substation exits. One solution selected was a cable-spacing system that features a compact configuration that reduces clearance requirements for wire on poles.

The cooperative gets power from more than 3,200 miles of line, and a mix of nuclear, coal, hydro, solar, and wind power provided by the Tennessee Valley Authority.

The fix

FLEC had used spacer cable in the 1970s to under-build a congested area, letting engineers add a new line by weaving it through the area without having to reconstruct the existing open-wire structure. The spacer cable was supplied by Hendrix, a New Hampshire-based firm that provides underground cable, cable spacers, tree wire, insulators, and other overhead transmission-pole products.

The spacer-cable system solves several tight space constraints. Kirkpatrick cites three reasons that it’s a good selection. Limited right of way is the driving factor because there is no way to obtain additional land for more open wire circuits. Second, the spacer cable gives designers flexibility with the number of circuits in the right-of-way corridor along with configuration and clearance requirements. Finally, the spacer cable allows use of existing poles. “We do not want to have to change poles, and it is relatively easy to add an additional circuit on an existing line using spacer cable,” says Kirkpatrick.

The power lines exit a substation serving a mountainous Tennessee community. Limited right of way is a big challenge when putting up new power lines because there is no way to obtain additional land for more open wire circuits.

Because much of the service area is in the foothills of the Smoky Mountains, FLEC tends to leave hardwood trees close to the circuit. So, falling softwood trees tend to be caught by the hardwood instead of falling on the line. FLEC still maintains clearances, but not as much as are needed with conventional open wire structures.

A closer look

Spacer-cable systems feature a compact configuration and reduced requirements for clearance which means multiple circuits (lines) can be installed on a single pole. Over or under-building spacer-cable systems in substation exits can greatly reduce the cost of adding capacity.

A spacer-cable system includes a messenger cable that supports the structure. For high-speed current collection, it is necessary to keep the contact-wire geometry within defined limits. This is usually accomplished by supporting the contact wire from above with a second or messenger wire. Its mechanical strength makes it suitable for long spans and it also serves as system neutral and lightning shield.

The system also includes polyethylene spacers to keep cables from rubbing and wearing. A series of spacers are clipped to the top of the messenger wire. The spacers support, separate, and clamp the phase conductors in a triangular or diamond-like configuration.

Spacers, placed between spans every 30 to 40 feet, install and come off easily. No ring ties are required. A built-in clamp accommodates a full range of conductor and messenger sizes. A wedge-shaped messenger hook provides maximum grip.

The spacers also have good weather-washing characteristics and their design provides high strength against short circuits. They are highly resistant to shock, impact, and rifle fire, and can be installed with hot-line tools.

Covered conductors consist of stranded, hard-drawn aluminum with three extruded layers, the thickness of which depends on a voltage rating. Hendrix’s proprietary, high density outer layer resists abrasion, electrical tracking, and UV degradation.

Also, reduced phase spacing is possible due to a three-layer covering that withstands temporary contact with tree branches and other vegetation, thus reducing outages and improving power quality. Along with the compact configuration, the system greatly reduces need for vegetation removal during circuit installation, thereby significantly trimming tree-trimming costs. The covering also protects wildlife from exposure to lethal currents.

Hendrix

Hendrix.com

Filed Under: News

What is the longest pole mounted arm you can get for spacer?

I am comparing this cable system (Hendrix) to the Ericsson Universal Cable system used in Europe….do you know anything about that cable and the pro’s and cons against the Hendrix system…..I knwo the Ericsson one is not sold in NA but it looks interesting….