Natural gas and wind power should be natural allies. They are not yet, but market forces may insist on the union.

Charles Vansant PE • Consultant, Golder Associates • www.golder.com

For the time being, there seems sufficient transmission for wind generated power. Natural gas, however, faces the challenge of getting to where it can be used.

Some of the biggest competition for wind power comes from natural gas. It’s abundant and low-priced, at this writing. (Ed. note: $3.69/Mbtu as of 9-5)

In many parts of the world, it’s difficult for wind power to compete without policies and programs that many governments have developed to help the industry establish itself. With significant growth in opposition to those support programs –and with some voices pointing to cheap, abundant natural gas as a better source of energy –many in the wind-power industry see natural gas as a competitor.

Understanding the relationship

To understand how gas-fired generation can actually be a friend to the wind power industry, consider some of the well-known barriers facing the greater growth of wind.

Being somewhat unpredictable, wind power’s availability does not correlate exactly with demand. Lacking anything like the ability of hydro-electric projects to store capacity behind a dam until power is needed, wind power is lost if it is not used when generated. Also frustrating for utilities, electricity generated through wind power suffers from quality issues, being variable in frequency and voltage.

Many members of the wind power industry are hoping that improvements in large-scale power storage will come to their support. Battery storage has significant potential to store most or all of the energy from a wind farm at night when prices are low and discharge it to the grid during peak times, while regulating the output of the entire facility.

It will be interesting to see how System Operators deal with this technology, because stored energy need not be discharged into the grid unless the price is right.

In the meantime, powerful political and economic forces are lining up against wind power and the subsidy programs that support it, threatening the ability of the industry to thrive until it develops large-scale power storage solutions. So, while those solutions are in process, there is need for a solution that makes wind power more acceptable to the market. Part of that solution may be natural gas.

Is current plentiful natural gas a bubble?

Some wind proponents might like to think that the current glut of natural gas, and consequent low prices, are transitory. However, much of the increase in supply is due to fast developing hydraulic fracturing technologies which can pull oil and gas from “tight” rock formations such as shale, which previously was uneconomic for the oil and gas industry. While there is significant opposition to hydraulic fracturing, largely because of the amounts of water it requires and its potential to contaminate aquifers, the benefits of made-in-North-America energy, and the strategic value of increasing U.S. energy independence, are likely too strong to put this technology back in its box.

One challenge facing natural gas, however, is getting it to where it can be used. An earlier gas glut in the 1980s encouraged the building of many pipelines to carry gas from the U.S. Southeast to the Northeast. Similar expansions have been good for delivery to market as well.

So with increased supply and availability of natural gas at historically low prices and quite possibly for long-term, is natural gas a viable way to help wind power? That is, can natural gas smooth out supply, meet peak power demand, and improve power quality by reducing fluctuations in voltage and controlling frequency? Let’s look.

Working together

Some types of gas turbines are not up to the task. Turbines designed for base load production are most efficient when operating at capacity and can meet environmental pollution requirements. When required to change their output level, they suffer significant losses of efficiency. Increased pollution would be the result if they were called upon to balance fluctuations in the power supply from wind.

Many of the most efficient installed turbines are combined-cycle. That means the exhaust heat from burning gas is used to heat water in a boiler, gaining more generation capacity per unit of gas consumed. However, older combined-cycle plants, in the 450 to 750 MW range, are particularly prone to lose efficiency when required to cycle up or down.

Many of the most efficient installed turbines are combined-cycle. That means the exhaust heat from burning gas is used to heat water in a boiler, gaining more generation capacity per unit of gas consumed. However, older combined-cycle plants, in the 450 to 750 MW range, are particularly prone to lose efficiency when required to cycle up or down.

Combined-cycle plants also need a good supply of water for their boilers, which limits where they can be located. They must also have a cost-effective and permitted way to dispose of the water removed from their boilers, called “blowdown,” which often contains a higher percentage of naturally occurring organic and inorganic materials such as metals, minerals, salts and other Total Dissolved Solids. What’s more, combined-cycle plants can be highly complex operations, requiring ongoing attention from skilled personnel.

Partly because simple-cycle gas plants (no boiler. The gas is used to run the turbine and the heat is vented to atmosphere) are easier to operate and can stay efficient even with rapid and frequent changes in demand, they may be a good fit with wind power. Simple-cycle plants do not require the 6 million gallons of water per day that a 750 MW combined cycle plant would need.

Small simple-cycle generators, in the 10 to 20 MW range or midsize in the 100 to 200 MW range, are particularly suitable for regulating wind power. That is, a simple-cycle plant of between 10 to 20 MW in size may be able to regulate five times that amount in wind-generated capacity. A 20 MW gas turbine may be able to regulate a 100 MW wind farm.

However, simple-cycle units are much less efficient than combined cycle. Gas turbine manufactures have invested heavily in fast start, combined-cycle plants, which have potential to integrate well with renewable resources. Features on newer turbines will let the plant vary from less than 50% of its rated output to 100%.

One reason gas-supported wind power works is that in many cases, the parts of North America with a strong wind resource (Wyoming and Kansas for example) also happen to be located close to gas resources or at least near a natural-gas pipeline.

It is not necessary to have the gas turbines located on the same site as the wind power project, although for smoothing, and voltage and frequency regulation, it is best to have the gas generator somewhere along the power corridor supplying the substation that connects the wind power and the load to the grid.

An example of cooperation

Eight 100 MW gas turbines provide high reliability as well as a sufficient output range. If each turbine operates between 50% and 100% of its rated load while complying with its emissions requirements, a minimum 50 MW output can economically rampled to 800 MW.

We are just now glimpsing the future of gas and wind working as partners. CPV, a major provider of asset-management services to natural gas-fired generation facility owners as well as a wind and solar power developer, has announced the CPV Sentinel Energy Project (SEP) for the Palm Springs, Calif. area. This is to be an 800 MW natural gas powered electric generation facility that consists of eight General Electric LMS100 aero-derivative combustion turbines. This project is intended to support the reliable integration of variable renewable energy resources into California’s electric grid.

Installing eight 100 MW gas turbines provides a great range of output and high reliability. If each turbine can operate between 50% and 100% of its rated load while complying with emission requirements, its minimum output is 50 MW (not 375 MW for a 750 MW 2×1 combined cycle), and plant output can be increased to 800 MW in an economic fashion. This project taps the idea of gas helping regulate renewable output, but does not actively regulate the output of a specific wind farm.

Another idea is to have the wind-farm owner predict wind output for any one period in the day-ahead market and hedge it with a natural-gas turbine at the same point of interconnection or equivalent.

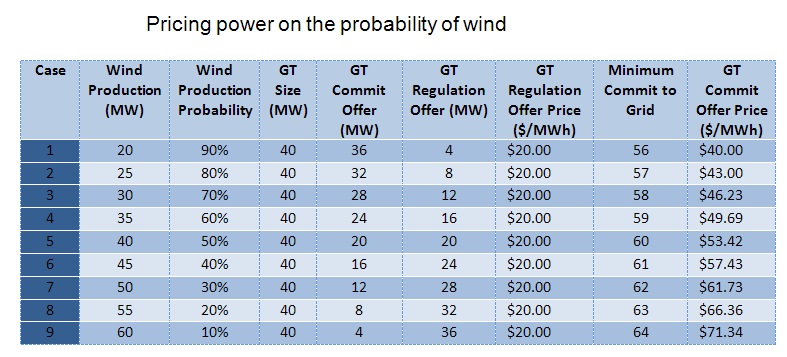

For another example, a 100 MW wind farm installs a 40 MW gas turbine to regulate its output. From the point of view of a system operator, the smallest output from a wind farm will be the rating of the gas turbine, and the largest output would be the rating of the wind farm plus the rating of the gas turbine. Hence, the wind farm could bid a mix of wind and gas based on the Wind Production Probability, Energy Price, and Regulation Price in the accompanying table.

Depending on the accepted offer from the system operator, the wind farm adjusts the output of the gas turbine (GT) to the “Minimum Commit to Grid” value. The higher the “GT Commit Offer,” the lower the amount of “GT Regulation Offer” can be offered and will ultimately be balanced by the “GT Commit Offer Price” which is determined from the “Wind Production Probability” and the wind farm’s appetite for risk. The wind farm accepts the risks of the “Minimum Commit to Grid” and should be compensated fairly when the minimum is met, and penalized when the minimum is not met.

In the above example, if system operator accepts the Case 9 price (in the table) of $71.34 per MWh, the wind farm accepts the risk of producing the difference between the rating of the 40 MW GT and the 64 MW “Minimum Commit to Grid”, or 24 MW using wind energy. The probability of generating 24 MWh by wind is a little more than 85% and the higher price should reflect the wind farm’s risk profile. Therefore, under the Case 9 pricing, the turbine generates enough power such that it produces a minimum of 64 MW. If the wind farm produces more than 24 MWh, the GT ramps down its production to something less than 40 MWh and saves on fuel costs. This example could be applied over a full 24-hour day, for 1 hour, or even for 15 minutes depending on the individual wind farm production characteristics and regional market structure.

As the “Wind Production Probability” changes in the accompanying table, so will the price offer for energy. Instead of having a total transmission system waiting to see how the wind blows, it would be better to have a gas turbine regulating a supply from a specific facility or area, to stabilize the power flow.

Unfortunately, the markets currently do not allow bidding a turbine into the market with increasing production costs, as was done in the example.

The market dictates that a turbine must bid in all of its capacity, even though the turbine is regulating the output of a renewable source and providing stability to an area. For this wind-farm example, as the wind produces more energy, less carbon is emitted, and the wind operator saves on fuel costs. This concept works well when gas is expensive, but because gas is now cheap, other incentives must be brought into the market to make this system economically viable.

Once energy storage devices such as batteries become commercially economical, they will tend to operate in a manner in which the size of storage facilities will be proportional to the size and production variation of an intermittent resource.

At a wind conference in February, Elliot Mainzer, Executive VP of corporate strategy for the Bonneville Power Administration, was reported as saying that his organization is studying the feasibility of market tools and an energy imbalance market, through a Northwest Power Pool group. WPE

Filed Under: Construction, News, Policy

The operator worries about the frequency anyway, why not allow the wind facility to bid their power into the market and aid the operator by providing some predictability on where the power is coming from?

Why limit wind penetration to 18% when you could have more, lots more? By requiring a the regulation a variable resource output by using a gas turbine or eventually energy storage, the need to consider variable resource penetration is reduced or eliminated. In addition, the utilization rate of the electrical lines built to transmit peak wind production will be much higher and will have the effect of reducing transmission costs for variable resources.

Synchronous generators provide smooth voltage transitions as they are analog based while wind facilities normally rely on Static Var Compensator (SVC) and capacitor banks devices which are digital in nature and produce sharp, stepped transitions when switched in and out of service that can cause additional wear on system components.

Charles Vansant

Golder Associates, Inc

A few points in response:

First, large amounts of wind energy are already being reliably integrated without new energy storage or new flexible power plants. There is plenty of very low cost flexibility already built into the existing power system.

http://www.awea.org/Issues/Content.aspx?ItemNumber=5452

This is because only a small increase in existing reserves is needed to reliably integrate wind. Grid operators already hold large quantities of flexible reserves to accommodate fluctuations in electricity demand and abrupt failures of conventional power plants. Even with 10,000+ MW of wind on the ERCOT power system, the total cost of increased reserves is about 50 cents/MWh of wind, or roughly 1% of current PPA prices. MISO also reports the impact of 10,000+ MW of wind on its reserve needs has been “little to none.”

http://www.uwig.org/slcforework/Ahlstrom-Session1.pdf

http://www.uwig.org/san_diego2012/Navid-Reserve_Calculation.pdf

As this article correctly notes, it does not make sense to have flexible resources dedicated to wind energy. Flexible resources are a resource to the power system, not to any one resource. The grid operator doesn’t care what one wind plant is doing, or even what all wind plants are doing, but rather they only care about the aggregate supply and demand of electricity. Changes in wind output are often counteracted by opposite changes in demand or in output deviations at conventional power plants, so trying to balance out changes in wind output is often counterproductive. As an analogy, it would be highly inefficient and counterproductive to have a dedicated resource accommodating fluctuations in the electricity demand at your house, as nearly all of those changes are canceled out anyway by other changes on the aggregate grid.

As a side note, Spain has been able to reliably integrate large quantities of wind and solar energy (Spain got 18% of its electricity from wind in 2012) with a large fleet of gas combined cycle plants and, to my knowledge, no combustion turbines.

Finally, wind can provide voltage support quite well on its own. As explained by NERC, the entity responsible for maintaining grid reliability in North America, which noted that modern wind turbines “may provide voltage regulation and reactive power control capabilities comparable to that of conventional generation.” (http://www.nerc.com/docs/pc/ivgtf/IVGTF_Report_041609.pdf, page 22) In fact, grid codes in most countries require wind plants to regulate voltage within a very tight band, just as conventional power plants do. Modern wind turbines have sophisticated power electronics that allow the turbine to provide significant voltage control at all times, even when the wind turbine is not producing electricity. As compellingly illustrated by the actual power system data presented in the chart in the middle of the following blog post, wind turbines can significantly improve power system voltage stability, indicated by the fact that power system voltage is much better regulated when wind turbine generators (WTGs) are online than when they are not.

http://aweablog.org/blog/post/correcting-fossil-fuel-industry-misinformation-about-germanys-success-with-renewable-energy

Michael Goggin,

American Wind Energy Association

A