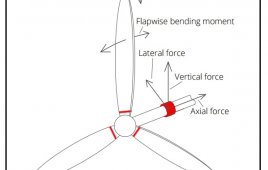

A physics based modeling approach can be used to establish a relationship between the forces acting on a component and the consumption of the component’s useful lifetime.

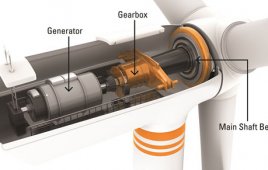

New Timken bearing aimed right at wind turbine main shafts

Timken Tapered Double Inner (TDI) Roller Bearing is designed to extend bearing life and improve system performance for three-point mount wind turbines.

Moventas Extra Life service concept expands to kilowatt-class gearboxes

Moventas has launched a kilowatt-class suite of life-extending services, Extra Life for kW. As older, kilowatt-class gearbox fleets age around the world, Moventas is ideally suited to extend the life of these components with its core technologies. Kilowatt-class gearbox fleet represent 12% of all gearbox fleets globally and 15% in Europe. Service for older gearboxes…

Kluber Lubrication offers rolling bearing grease for enhanced protection against friction and wear

Klüber Lubrication, a worldwide manufacturer of specialty lubricants, has announced the availability of Klübertherm HB 88-182. This new product is a versatile long-term grease that provides good corrosion and wear protection for rolling bearings subject to high loads and medium speeds at temperatures of up to 180° C. Klübertherm HB 88-182 is fully synthetic and based…

AeroTorque Corp announces the Double Your Warranty Program at WINDPOWER 2016

The new program, called “Double Your Warranty” offers

added protection for new bearings installed up tower

Motion Industries launches bearings.com knowledge website

Site visitors have access to a wide array of content on the subject – including articles, videos, white papers, training materials and more.

Bearing manufacturer Timken selected as one of world’s most ethical

Timken is one of 131 organizations selected as a 2016 World’s Most Ethical Company.

Getting blade bearings in shape for the turbines of the future

Blade bearings might not exactly be the most expensive components in a wind turbine, but damage to this fundamental part of the system can result in considerable downtimes and costs. By designing and testing blade bearings under realistic conditions reliable operation of future turbines shall be improved. In the HAPT research project (short for “Highly…

Global wind turbine bearings market projected to reach $7.8B by 2020

Wind power generation has been a proven technology and emits no carbon dioxide. It has gained widespread acceptance as the cleanest and most environmentally friendly form of energy. The increasing reliability of the system, especially the wind turbine, while reducing the operating expenditure remains a challenge in the wind power industry.

A little flexing and synthetic lube may be better for wind-turbine and tidal-water gearboxes

A flexible-pin gearbox that improves load sharing between the various gear elements makes it valuable for high peak load applications, such as wind and tidal-power turbines.

Timken expands its service center in Pasco, Wash.

Large electric motor, wind generators and industrial gearbox repair services available for customers in the Pacific Northwest The Timken Company has opened a 70,000-square-foot, state-of-the-art motor and gearbox repair facility adjacent to its existing service center in Pasco, Wash. Built to enhance service to Timken Power Systems’ (TPS) customer base throughout the Pacific Northwest, the…

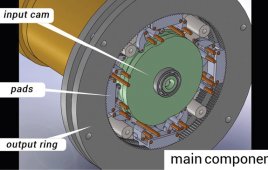

Unconventional speed reducer could take weight & cost off a turbine

If wind turbines are to be built larger, their designers will have to think differently about building larger components. An inventor in Dallas wants to assist with a recent design for a pitch drive could take weight off a rotor and a turbine’s main bearing. The clever cam-activated mechanism turns a ring gear by “walking”…

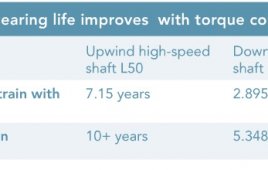

Gearbox model predicts longer bearing life with controlled torque reversals

RECENT PERFORMANCE MODELING of wind-turbine-gearbox bearings with field data suggests that taming torque reversals could lengthen a gearbox-bearing life up to two fold. The field data was collected by engineers at AeroTorque and supplied to bearing simulation and prediction firm Sentient Science. The later company has collected data on millions of military aircraft bearings and…

Manufacturer duplicates bearing race smearing in lab and identifies a resistant coating

Wind turbine gearboxes are a little more reliable since researchers at The Timken Company have been able to reproduce smearing damage on bearings in the lab. Producing it means they know what causes it, and later tests on selected surface treatments show that one works well eliminating the damage. “Smearing is a damage mechanism in…

Bearing sensor could let wind-turbines bearings talk

Engineers from the University of Sheffield have developed a novel technique to predict when bearings inside wind turbines will fail. A method, published in the journal Proceedings of the Royal Society and developed by Mechanical Engineering research student Wenqu Chen, uses ultrasonic waves to measure the load transmitted through a ball bearing in a wind turbine.…

Morgan offers new grounding brushes and holders for longer bearing life

Morgan Advanced Materials’ Electrical Carbon business recently announced new grounding brush holders, designed for stability and reliable dissipation of current to prolong bearing life. The grounding brush holders have a contact drop of less than one volt because to their high quality silver-graphite brush. DC motors applied on static drive systems and AC motors on adjustable-speed drives…

Timken researchers address critical issue for wind turbine operators

Research conducted by The Timken Company to address a critical issue for wind turbine operators received the 2015 Wilbur Deutsch Memorial Award from the Society of Tribologists and Lubrication Engineers (STLE). Timken researchers solved customer problems in the wind energy sector and underscored the value of Timken wear-resistant bearings in helping to prevent smearing damage to turbine…

Turbine components: bearings

Where are bearings used in a wind turbine? Although bearings are used many places throughout a nacelle, such as in the yaw and pitch bearings and on the generators, those on main shafts and gearboxes are most problematic. In main-shaft bearings, modular wind-turbine designs commonly use spherical-roller bearings (SRB) units that are more than 1m…

Morgan’s electrical carbon business offers grounding brush holders for longer bearing life

Morgan Advanced Materials’ electrical carbon business recently announced the release of its grounding brush holders, designed for stability and reliable dissipation of current to prolong bearing life. The grounding brush holders have a contact drop of less than 1 volt due to their high quality silver-graphite brush. DC motors applied on static drive systems and AC…

Trends in bearings

Bearing trends mainly focus on extending bearing life and reducing issues with wear, which is the primary cause of turbine-component failures, a problem that has long plagued the wind-energy industry. Due to this, many OEMs have accepted the challenge to developing and perfecting a high-performance bearing. The goal is to catch a bearing problem before it…