By Neel Sheth, Wind Power Application Engineer

Mersen | mersen.com

Brushes play an important role in wind-power generators. A brush is an electrical conductor subject to friction. It works as a mechanical and electrical component that has the function of transferring a current (ac or dc) between the rotating part of a machine and its fixed external power supply or power converter.

A brush is typically expected to operate efficiently within a wide or narrow range of speeds and electrical loads. How it performs, however, depends on the brush material (also called brush grade) and the system assembly. Choosing a brush for an application consists of best matching its mechanical and electrical properties to the operating conditions of the machine.

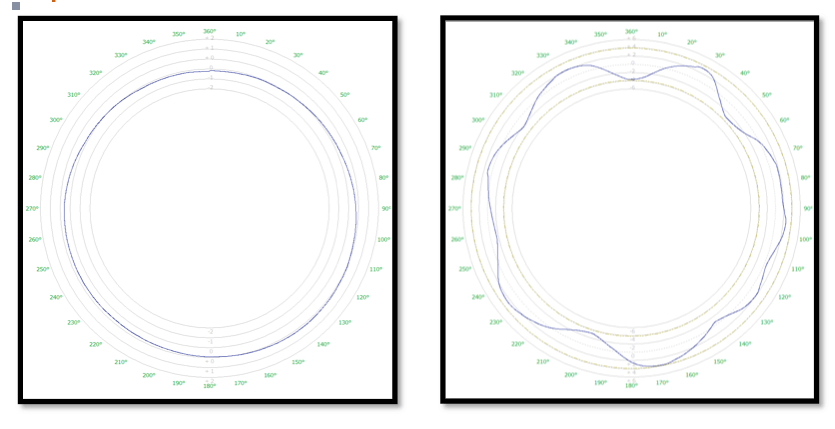

Slip-ring profiles obtained using an advanced digital profiler tool. The diagram on the left shows an almost perfect ring, while the one on the right shows a damaged ring in need of immediate attention. Advanced digital tools are available on the market to analyze slip rings and provide outputs as shown.

Although a relatively small component, the performance of brushes in wind-turbine generators is key to efficient operation.

What makes a good brush?

A good brush must have a set of electrical and mechanical properties, some of which are more important than others. Two essential properties include reliable wear and compatibility with the slip ring.

- Moderate wear: A brush is a wear item — a consumable. That means it has a minimum life, which is important to note for its intended application to best optimize replacement schedules and maintenance intervals for the rotating machine.

Excessive brush wear typically causes carbon dust generation in the slip-ring cabinet, which increases the risk of reduced internal insulation. This may lead to additional maintenance costs and the risk of an arc flash (also known as a flashover), as a result of the phase-to-phase conductive dust covered surfaces in the slip-ring cabinet.

Moderate or adequate brush wear is key to proper generator and wind-turbine O&M.

- Slip-ring compatibility: A brush must maintain a good surface finish of the slip ring on which it’s operating. The surface finish must remain stable so there is no diminishing of brush performance over time. This includes surface roughness and runout (which is the shape profile or “roundness”) of the slip ring. Unfortunately, repair or replacement costs of a damaged slip ring are high, and can cause unexpected shutdowns and equipment downtime.

Finding a match

A quality brush application must also consider the slip ring’s material. This is because a good brush features a long life without damaging or wearing into the slip-ring surface. Together, the two components must work together while minimizing wear of the brush and slip ring.

The optimum brush is found when its mechanical properties match the specific application without compromising a slip ring, and while fulfilling its electrical requirements. A damaged slip ring may be a sign that the brush used is unsuited for the application.

Damage detection

An improper brush can damage its slip ring. The most frequent damages and their root causes are:

- Slip-ring wear: Optimizing metal content and material hardness of the brush material is critical. Improper spring tension or an excessively hard brush grade can cause high friction at high speeds, and cause slip-ring wear by mechanical abrasion. Therefore, spring tension and metal content of a brush slip-ring system is an important consideration during the design stage.

- Abnormal temperature rises: If the temperature of a brush or slip ring exceeds the manufacturer’s recommendations, damage is likely to occur. This could happen because of a mechanical issue (such as high friction) or an electrical issue (such as electrical loads exceeding the current carrying capability of the brush).

- Arcing, burns, or micro-pitting: These are indications of fatigue failure on the surface of a material, typically seen in rolling bearings and gears, although they also show up in slip rings as well. Such wear typically means a brush is unable to handle the electrical loads, or that the brush material or the surface of contact between the brush and the slip-ring are incompatible. This electrical phenomenon can cause local or repetitive deformations. It can also do worse damage and destroy the slip-ring surface making it abrasive to the brush and resistive at the same time.

- Slip-ring deformation: This happens when a slip ring is “out of round,” which can occur on both phase and ground rings. On grounding applications, shaft currents leaking into the grounding system can lead to rapid slip-ring deformation when the application uses an improper brush grade. High-frequency ground discharges act as electric discharge machining on the ring, causing low or flat spots on the ring over time. This phenomenon is often referred as ghost marking.

Slip-ring design

Choosing the right brush for the application is only part of the answer for the best brush and slip-ring performance. The proper slip-ring design is just as critical.

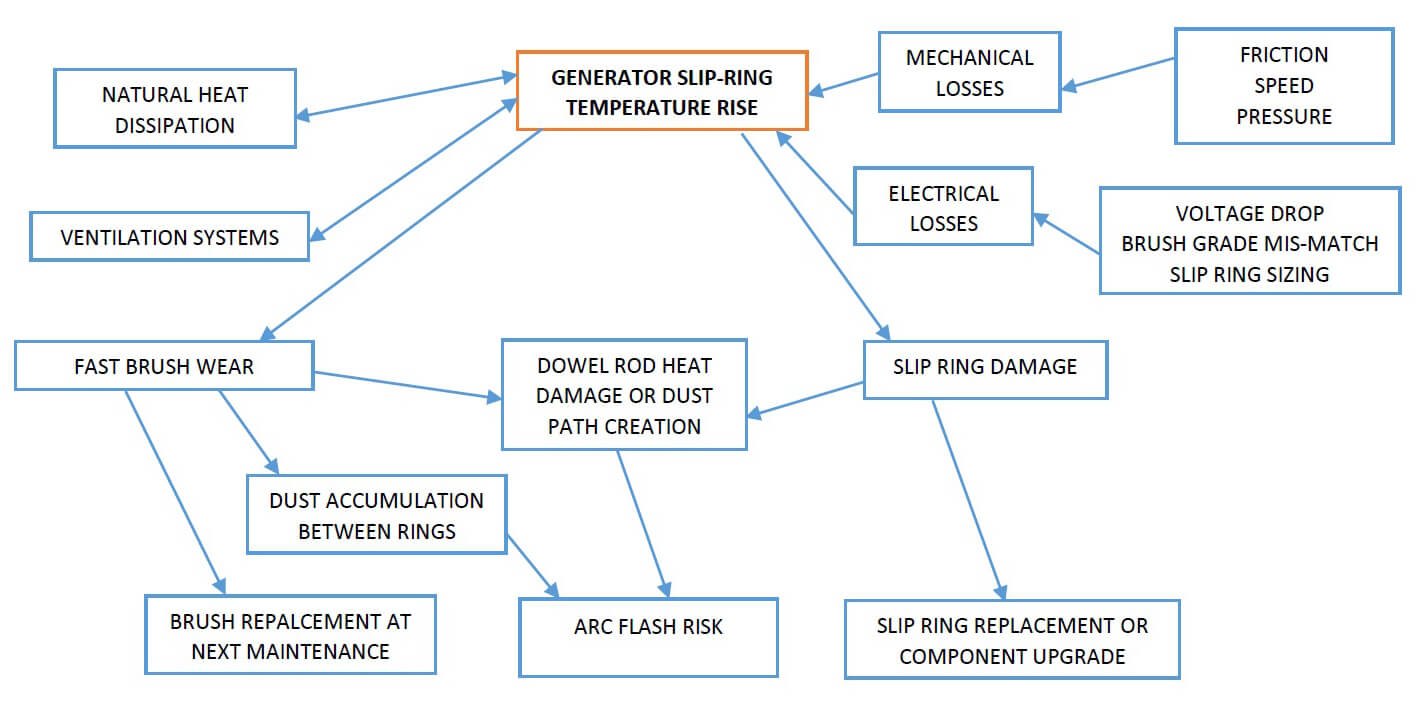

As the system temperature in a wind-turbine generator increases abnormally, the risk of excessive wear increases for the brushes and slip rings. This may lead to arcing from the brushes to the ring or across rings — from phase-to-phase or phase-to-ground. Incorrect system design can also contribute or accelerate the failure rate on these components. This flow chart shows the relationship between various factors, which affect slip-ring temperature, and how it may affect the general condition of a machine.

A number of slip-ring designs are currently available for wind-energy applications. Design criteria should account the electrical loads (rotor current loads) of the turbine generator. The generator rotor electrical loads, in comparison with the targeted slip-ring S-factor (surface factor), define the slip-ring sizes required for an application.

The S-factor is a simple key design factor used by experts to accurately size slip rings for a machine. It is calculated as a ratio between the slip-ring surface width over the nominal current, and is directly correlated to heat dissipation factor of the system. This S-factor co-efficient can be used to quickly evaluate the degree of difficulty of a motor or generator, and guide installers to the right brush grade for the application. A brush-slip ring manufacturer should use this outline as the basic design guide when designing or customizing systems for today’s highly demanding applications.

The choice in ring material or design of slip-ring ventilation directly affects the acceptable S-factor requirements. A well-ventilated bronze slip ring would typically offer better performance than an equivalent size stainless steel ring with poor ventilation, even when featuring the same S-factor.

Bronze generator slip rings are becoming more common in the wind industry, and were introduced as replacement components for the original stainless steel versions. Bronze slip rings for generators significantly improve the overall performance of these systems. In fact, brush wear rates and operating temperatures drop by as much as 30 to 40% when a slip ring is correctly designed based on these factors.

The ideal brush

Motors or generators (synchronous and asynchronous), and all rotating systems using slip rings, employ technologies that are different from those used on dc motors. The technological requirements also differ.

Many factors come in consideration when choosing the right brush grade, such as:

- The slip-ring design: Alloy, size, and helical groove

- The brush-holder design: Number of brushes and coverage ratio of the ring

- The system design: Current loads, rpm, spring pressure, and ventilation

A detailed understanding of a heat source or hot spot in a brush slip-ring system is necessary before identifying a heat dissipation method. Of course, this method depends on system size. Therefore, it is important to consider the brush grade and design along with the slip-ring design.

The choice of metal content (typically copper) is also an important consideration. Brushes that wear evenly across all phases indicate good performance over a given set of operating conditions. The brush-contact-surface aspect is also a good performance indicator. Pitting marks or heavy streaking on the other hand, are signs of overload or grade mismatch. There is a wide range of brush grades for slip rings, and the metal content can vary from 0 to more than 90%.

The number of brushes and brush sizes needed in a system is determined by the current load to transfer. The current capability of the brush grade chosen is typically quantified in terms of “Current Density” (Amps/cm2). The higher the metal content of a brush grade, the higher the current density (or current capability), but the lower the peripheral speed of the slip ring. The metal content in the selected brush should be inversely proportional to machine speed. Based on the intended application, manufacturers normally recommend a speed range for a brush grade.

In summary, the application’s component wear and operating temperature indicates whether or not the brush grade is appropriate.

This article was part of our 2018 Renewable Energy Guidebook. View the full publication here.

Filed Under: News

Hello,

I have an Aleko 48v wind turbine. When it was shipped I noticed two of the brushes were broken.

I fabricated some replacements from parts of a previous turbine.

As I read about this wear phenomenal it seems it is more complex than just the brushes (and potentially more damaging). Obviously the really critical part of the whole equation is not wanting to spend the time replacing the brushes when the entire unit could crap out at any time. Right now, performance (power delivery) has dropped significantly.

I live in the tropics in a very saline environment. Are there any units in the 2000-3000w range you’d recommend for durability and over quality, including resistance to corrosion?