The Dearman Generation 2 engine appears to be a two-cylinder version. By running on liquid air, the exhaust would be… air, and no NOx of any sort.

A clever Englishman and inventor, Peter Dearman, suggests running cars and trucks on a fuel limitless in supply: liquid air. Think about it. A liquid-air engine would have zero pollution and lack the complexities of a lithium battery or fuel cell. You might be surprised to learn that the idea is not new. Earliest reports of it arise in the late 1890s!

Of course, liquid-air is not really a fuel, something that would combust, but rather something that would expand in a warm cylinder (warmer than -320°F) to push a piston. This should interest the wind industry because air liquefiers would run by way of electric motors, lots of electric motors, which would boost the demand for power and spur more growth in the electric power industry than the anemic 13% expansion (not annually) that Federal agencies expect over the next 10 years.

The Dearman website says it is delivering clean ‘cold and power’ and that it is developing a portfolio of proprietary technologies, products, and services to deliver significant reductions in operating cost, fuel usage, and emissions, at low capital cost. The company has also announced that testing of its engine has begun at its new liquid air R&D facility.

The first application of the engine will attempt to cool London’s refrigeration trucks. Oddly the Lair engine will drive conventional compressors. Current refrigeration units are powered by unregulated diesels that, by one calculation, pump the equivalent of 49,120 tons of CO2, 163 tons of NOx, and 22 tons of particulate matter into London air every year. And if the test is successful, the next possible target: automobile engines.

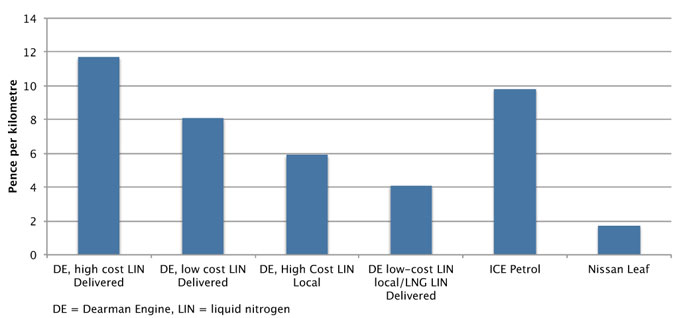

Of course, a few questions remain, such as: How will it function in winter? What power can it develop? What would be the cost per mile?

Graph: Cost per kilometer of Dearman engine car compared to ICE and EV (Source)

The physical properties of air provide some clues. At standard temperature and pressure, air has the density of 1.2754 kg/m3. It liquefies at -355° F and has a density about 870 kg/m3, so the expansion ratio is about (870/1.2754) 682. The engine would operate more like a steam engine than an internal combustion variety. It would have high torque at low speed and the liquid air could probably go through several expansions, although the site suggests the current design uses just one expansion.

Miles per gallon will be meaningless for comparison to convention engines but Mr. Dearman has anticipated the question and so provides the accompanying blue bar chart. Read the Dearman manual at this link.

One significant advantage of such an engine over an EV or fuel-cell car is fast refueling. Dearman says liquid air can be transferred between vessels at high rates. The industrial gas industry has developed filling systems capable of >100 liter/min (more than 25 gal/min) transfer rates.

As for availability of the fluid, U.K.-based Spiritus Consulting estimates that excess nitrogen (78% of air) production capacity in the U.K. already amounts to at least 8,500 tons/day. Current practice returns the gas to the atmosphere because argon or oxygen is more valuable. The thermo-physical properties of air and nitrogen are similar, and either could serve as a cryogenic energy vector. In the early stages of a liquid air economy, therefore, waste nitrogen gas could be liquefied to use in place of liquid air. If the entire estimated daily nitrogen surplus was used for this purpose, it could absorb 4.6 GWh of ‘wrong time’ wind generation and at 60% round-trip efficiency, potentially powering the equivalent of 6.5 million car-kilometers daily.

The idea might be a bust again but until then, its concept offers another option to power our economy. And if moderately successful, it could serve to store excess electrical energy. Right now, everything hinges on a successful refrigeration test.

Added July 15: By way of an update, a company spokesperson says that on-vehicle testing is going well and the company anticipates its first commercial field trial to commence in the coming months of 2015. The Chief Technology Officer, Nick Owen, has written a neat piece on how the Dearman refrigeration system works, and explains the economic and environmental benefits of using a cryogen as our working fluid.

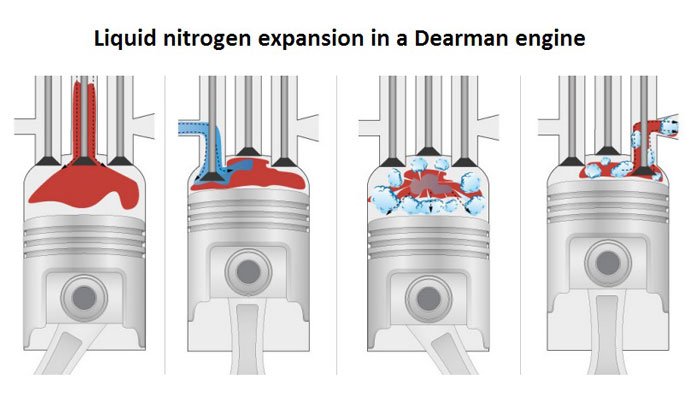

How a Dearman engine works

The Dearman engine builds on well-understood piston engine technology but includes proprietary heat exchange techniques that increase the efficiency, applicability, and cost benefits of the engine.

The engine works like this, from left to right:

- A heat-exchange fluid (red) is pumped into the engine, filling most of the cylinder volume.

- Cryogenic nitrogen (blue) is then introduced to the cylinder, coming into to contact with the heat-exchange fluid where it begins to expand.

- Heat from the exchange fluid is absorbed by the expanding gas, causing near-isothermal expansion.

- The piston is forced down, the exhaust valve opens, and a mixture of gas and heat-exchange fluid exhausts from the engine. Also, the heat-exchange fluid is reclaimed, reheated, and reused, while the nitrogen or air is released back to atmosphere.

Filed Under: Featured, News

Good article. One error though: the inventor is Peter Dearman. Michael is his son who also works at Dearman as a self taught senior engineer!

Ferdinand Berger

Sponsoring Peter’s invention since April 2002; presently senior non exec Director Dearman Engine Company.