A compact, fine-dust sensor, the FDS 15 from Dr. Födisch Umweltmesstechnik AG, provides a smart instrument that determines fine dust concentration (PM 2.5).

Each person daily inhales about 15,000 liters of air. Unfortunately, the air contains invisible pollutants, which vary in composition and concentration depending on the location. The respirable particles with a diameter of less than 2.5 µm (PM 2.5) are considered particularly dangerous. For instance, according to a current study conducted by the Max Planck Society, worldwide 3.3 million people annually die prematurely due to air pollution.

European emission limits and emission guidelines should control the respirable dust pollution. A limit value of 25 µg/m³ has existed since 2015 in the annual average throughout Europe. This value will be reduced in 2020 to 20 µg/m³. The conformation of the limitation values were controlled by 170 regulatory measuring stations of the Federal Environment Agency in Germany. According to their results, the fine dust pollution has diminished over the last few years at both national and regional level, but the trend stagnated since 2013. (Source)

Comprehensible to everyone is that fine dust pollution rises in urban and suburban spaces, whereas in rural areas the values decrease. Combating the causes is more difficult than the responsible persons thought.

Weather-related influences adversely affect the measurement. Regulatory measuring stations, as required to gain reliable measuring values, are technically sophisticated and cost-intensive. Currently six regulatory measuring stations in Stuttgart were installed.

A compact fine dust sensor, the FDS 15 from Dr. Födisch Umweltmesstechnik AG, provides a smart, fine-dust-measuring instrument that determines the fine dust concentration (PM 2.5). Previous trials in Germany and China correspond well to the regulatory measuring stations. Every two seconds, a measuring signal is transmitted to the receiver. Depending on the customers’ requirements the determined values can be averaged over minutes or hours. Due to the continuous measuring principle, the values contain a high level of information density and have therefore also a great expressiveness.

A WLAN-capability allows connecting several sensors to precisely tell where and when fine dust pollution comes from. This is shown by the evaluation of our test results.

How it works

Two optical sensors form the centerpieces of the FDS 15, which determine the dust content on basis of the scattered light method.

The air drawn in is preheated to 50°C and maintained constantly on this level. In this context, it doesn´t matter what the weather is like or which measuring location is selected. A fan produces flow and guarantees air exchange. With the establishment and design, we have put emphasis on compactness. For more technical details, the technical datasheet is here.

One fine-dust sensor, many application possibilities

This device is applicable to stationary or mobile use to control air quality indoor and outdoor, which plays an important role in workplace air quality monitoring for instance in factory buildings. The FDS 15 can also be integrated in urban agglomerations e.g. on street poles or transport hubs. Airports, public buildings and industrial areas were also addressees.

The fine dust sensor FDS 15 can be used very versatile for example:

- Air management system (ventilation control)

- Air quality system (supplement to air quality monitoring systems, CO2-concentration measuring systems in rooms

- Workplace Monitoring

- Filter Monitoring in terms of air return

- Ambient Monitoring

- Controlling tool (detection of diffuse emission sources)

- Benefit-Kit (additional device for meteorological stations)

The advantages are clear:

- Regardless of weather conditions

- Continuous fine dust measurement

- Attractively priced, industrial-suited measuring device

- Easy data-output via standard interface

- Low maintenance operation

- Robust construction and compact design

This makes the FDS 15 to a manageable and true all-rounder looking for their equals.

Precise fine dust monitoring under test conditions

The FDS 15 was tested under different conditions in practice. Three results are here:

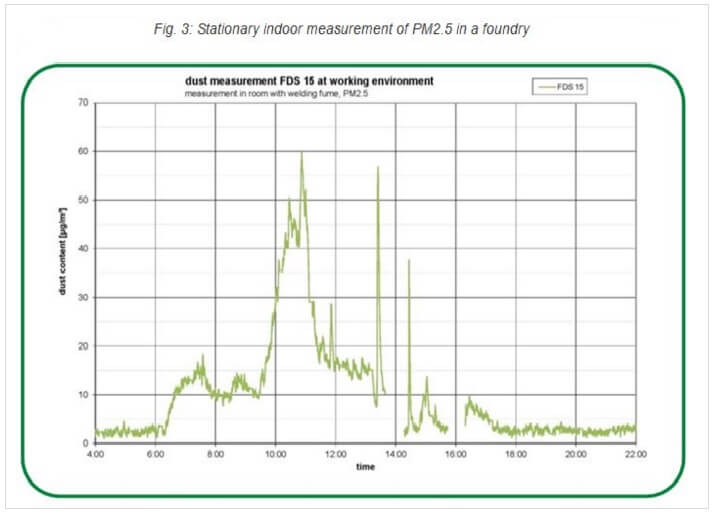

At New Year’s Eve the fine dust pollution reaches concentrations that were never as high as on this annual event. The analysis of the measuring results clearly shows the impact of weather phenomena on dust content. A change in the weather facilitates air exchanges. In the rain, air pollutants can be “washed out”. Normally, the lower air layer is warmer than the layer above. In times of atmospheric inversion, the upper air layer is hotter than the layer beneath, so that the air exchange is blocked. The pollutants contained in the air were captured at ground level and accumulated over hours and even days. We observed these high air pollution concentrations on 02.01.2016 in Leipzig.

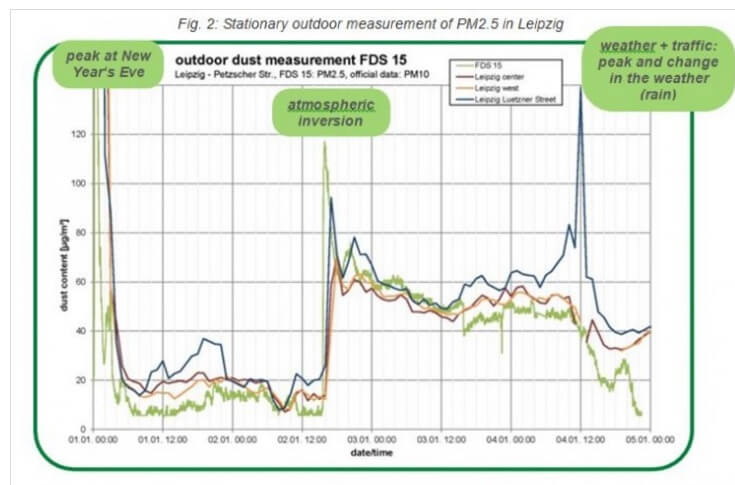

In a foundry we determined the fine dust concentration, averaged over five minutes, caused by welding fume. The analysis clearly shows at what time production-related work peaks occur. The continuous measuring principle offers the opportunity to monitor air quality at the work place and to control exhaustion and filter systems in order to improve the quality of production processes and preventive health care of employees. Therewith energy can be saved since the exhaustion capacity is adjusted depending on the real measured dust load.

Not least because of our mobile measurements, performed together with our cooperation partner G. Lufft Mess- und Regeltechnik GmbH and the mobile weather sensor MARWIS, unveils excellent results, above.

In 1991, the company called Dr. Födisch Umweltmesstechnik AG was founded to develop advanced measuring devices to monitor environmentally harmful and health-damaging exhaust gases in the air. This led to a product portfolio comprising over 25 devices that measure in a variety of ways dust, gas concentrations and volume flows. The measuring principle of the FDS 15 is based on an optical measuring method that provides a basis for further updates of the dust measuring devices. The optical determination of any type of dust concentrations will also be integrated into future developments to make the measurement both more effective and precise for the user.

More than 11 000 dust-measuring devices and gas analyzers are already today in use all over the world. At the head office in Markranstädt near Leipzig, 72 employees develop and produce measurement devices “Made in Germany” and implement individual system solutions.

A record turnover of €19.5 million was generated by the end of the year 2015. Among other things, this is attributable to the entry in new sales markets such as China, where the degree of the air pollution is far larger than in Germany. The export share amounts 56%.

The present customer base consists of power plants, waste incinerators, biomass and sewage sludge, installations of the chemical and metallurgical industry like foundries or copper production industry. By means of the fine dust sensor, the customer base should be extended to automobile manufacturer and suppliers, municipalities, meteorological institutions or airport operators.

Visit our website at www.foedisch.de. E-Mail: vertrieb@foedisch.de

Filed Under: News, Sensors