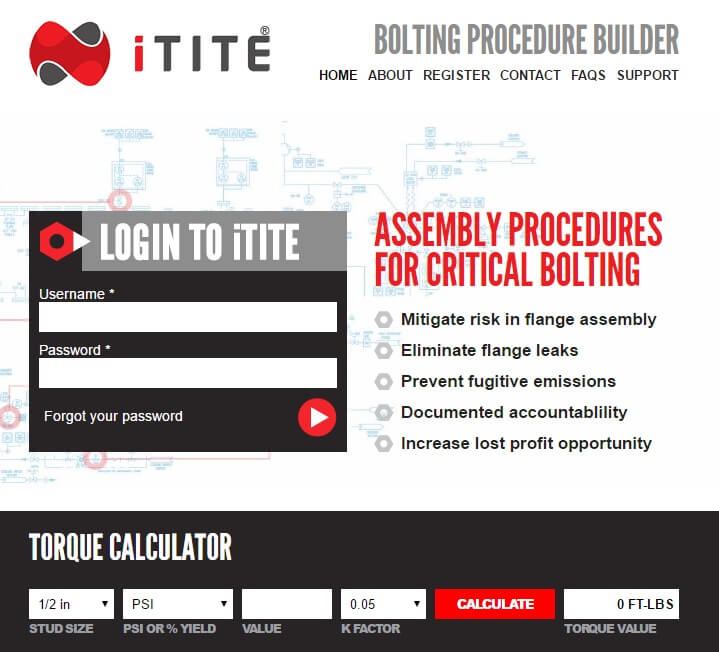

iTITE, a cloud-based Engineering Tool, calculates bolt load, determines torque or tension values, and then applies them to an Assembly Procedure based on the latest engineered standards as found in ASME PCC-1-2013 and others. The software allows managing bolt patterns and flange procedures.

In a simple three step process, iTITE identifies the maximum limit of bolt stress allowable on custom or ANSI flanges and populate this data into an easy to read graph that displays limiting factors for the flange size entered. The system provides for the maximum bolt stress allowable without damaging the following components:

In a simple three step process, iTITE identifies the maximum limit of bolt stress allowable on custom or ANSI flanges and populate this data into an easy to read graph that displays limiting factors for the flange size entered. The system provides for the maximum bolt stress allowable without damaging the following components:

The flange

Based on finite-element analysis, the system catalogs the FEA results of ANSI flanges and uses that data to identify the point at which plastic deformation or flange rotation will occur. Based on that data, it is compared to other factors and a recommended bolt stress is safely reduced below that level. The assembly data will be specified as a bolt stress without risk of deflection or mechanical failure.

The bolts

Based on the material of the bolts, iTITE determines how much bolt stress can be generated. The system also takes into account the nut factor, or “K” factor used when torque is the method used in assembly.

The gasket

iTITE calculates the gasket stress based on the gasket type selected and the size of the gasket based on ANSI dimensions or custom values the user inputs. The system calculates gasket stress into bolt stress based on the flange dimensions entered providing the user with the final limiting factor. The system has been in use since 2011. For more: http://alltite.com/

Filed Under: Construction, O&M