The Composites in Wind Workshop, held at NREL’s National Wind Technology Center in Boulder, Colorado, featured over a dozen sessions led by subject matter experts.

Over 150 students, academics, technicians, and business owners from 27 states now have a better understanding of the latest developments in advanced materials and processes, thanks to attending a two-day school presented by Composites One.

The Closed Mold Alliance and Magnum Venus Products (MVP) is in partnership with the Institute for Advanced Composites Manufacturing Innovation (IACMI), one of eight organizations comprising the National Network for Manufacturing Innovation. The Energy Department’s National Renewable Energy Laboratory (NREL) also participated in producing the workshop.

“The Composites One – IACMI partnership continues to grow, and the goal of educating the next generation of composites professionals, along with today’s workforce is coming to fruition,” said Composites One Director of Marketing Communications Marcy Offner. “Comments from attendees were all positive, and companies like Siemens, GE and Vestas were all impressed by the content of the workshop.”

IACMI – The Composites Institute CEO Craig Blue agreed, adding, “Training the workforce to support the anticipated growth in the advanced composites industry demonstrates IACMI’s commitment to the State of Colorado and other partners. Successful integration of innovative technologies such as advanced composites depends on a number of critical factors, including availability of a skilled workforce with hands-on training in advanced materials.”

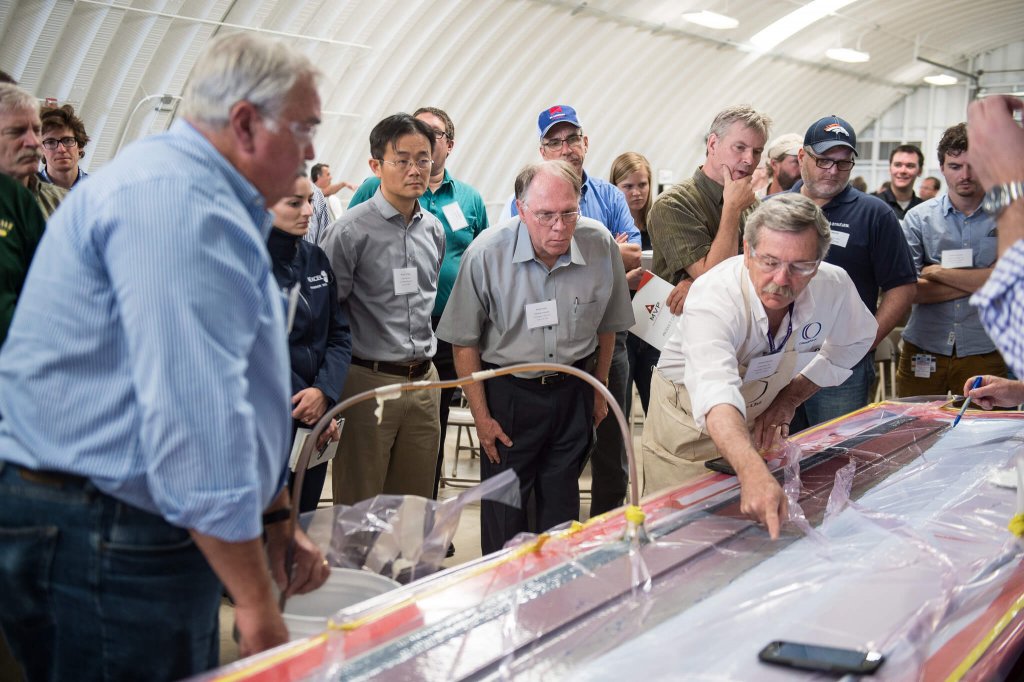

Held June 14 to 15 at NREL’s National Wind Technology Center in Boulder, Colorado, the Composites in Wind Workshop featured over a dozen sessions led by subject matter experts from Composites One, the Closed Mold Alliance, IACMI – The Composites Institute, NREL, and Magnum Venus Products (MVP). They included live demonstrations of Vacuum Infusion, Light Resin Transfer Molding, and repair methods.

Ed Pilpel, President of Polystrand, presented a keynote address discussing advances in thermoplastics.

The two-day Composites in Wind workshop brought together over 150 wind-industry professionals for training in advanced materials and processes.

“The Composites in Wind Workshop would not be possible without the expertise and support of our supplier partners,” said Offner. They include 3A Composites, 3M, Airtech, Ashland Performance Materials, Chem-Trend, Chomarat, Gurit, ITW Wind Group, MVP, Mankiewicz, Owens Corning, Polynt, Pro-Set, SikaAxson, Soul Composites, United Initiators Inc., and Vectorply.”

Following this event will be two more workshops this year (check compositesone.com for dates and registration details):

- Process & Advanced Materials Workshop – West Lafayette, Indiana

- Process & Automotive Market Advances in Composites – Detroit, Michigan

All are designed to help participants become more adept in advanced and closed mold processing, out-of- autoclave production, additive manufacturing (3D printing) light-weighting of products, prototyping, selecting systems and equipment, advancements in composites and high performance materials, data acquisition, modeling, and simulation.

Experienced process experts will lead sessions from Composites One and the Closed Mold Alliance, a resource dedicated to helping manufacturers make a successful conversion to closed mold and other advanced processes, and IACMI. Along with Composites One, the Closed Mold Alliance founding members include Magnum Venus Products and RTM North Ltd.

Filed Under: Blades, News, Training