Several wind companies will present techniques for uptower repairs, including demonstrations on blade fillers, sealants, and structural repairs.

Registration is now open for Composites in Wind, a free, two-day school on advanced materials and processes for wind energy applications, presented by Composites One in partnership with the Institute for Advanced Composites Manufacturing Innovation (IACMI), one of eight institutes comprising the National Network for Manufacturing Innovation.

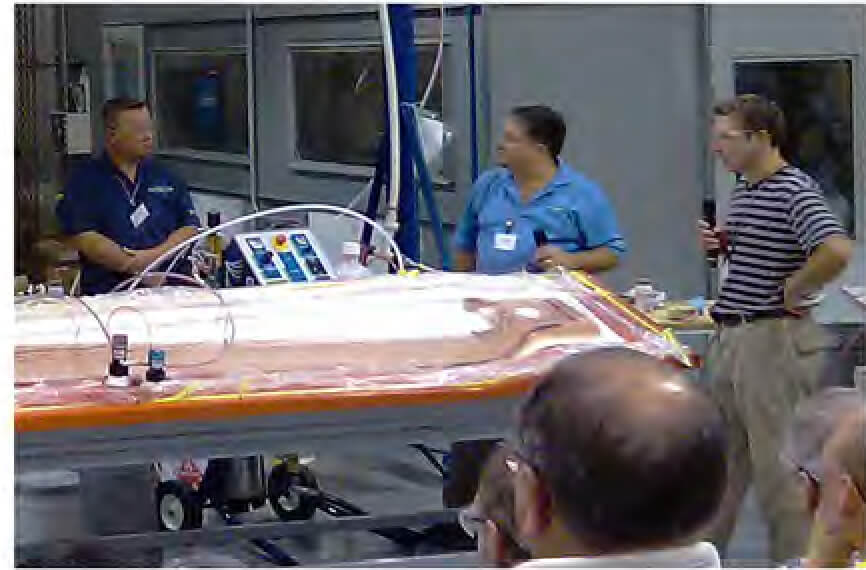

Featuring live demos, a repair and rehab workshop, and presentations on the industry’s latest developments, the event will take place June 14 to 15, and will be hosted by the Energy Department’s National Renewable Energy Laboratory (NREL) at their National Wind Technology.

“This is a very exciting event for us,” said Composites One Marketing Communications Director Marcy Offner. “Of the live demos and educational workshops that we’ve presented the past few years, we have always drawn large crowds focused on advanced materials and processes for wind energy components. This is an opportunity to go beyond those programs and present the latest advancements at NREL’s National Wind Technology Center, the nation’s premier wind energy technology research facility.”

IACMI CEO, Craig Blue agreed, adding, “This collaboration reinforces our mission to advance and expand the existing composites workforce ecosystem in preparation for rapid developments in composites manufacturing.”

According to Offner, NRELs National Wind Technology Center is the perfect venue for this session. Located at the base of the Rocky Mountain foothills, it occupies a 305-acre site that experiences diverse wind patterns, occasionally exceeding 100 miles an hour, which makes it ideal for testing the reliability and performance of wind turbines.

Major wind manufacturers and OEMs will discuss changes in composite materials and material qualification processes, as well as provide information and demonstrations for controlling the rate of leading-edge erosion on blades.

At Composites in Wind, attendees will be able to tour NRELs wind testing facilities first-hand and:

- See LIVE demos of vacuum infusion building a wind blade, and Light RTM building a nacelle.

- Hear about the latest developments from wind OEMs and operations professionals.

- Experience an up tower wind blade repair and rehab workshop.

- Find out about the latest advancements in plugs and tooling.

- Learn how to ensure worker safety, control blade erosion and more

Experienced process experts will lead sessions from Composites One and the Closed Mold Alliance, a resource dedicated to helping manufacturers make a successful conversion to closed mold and other advanced processes, and IACMI. Along with Composites One, the Closed Mold Alliance founding members include Magnum Venus Products and RTM North Ltd.

“Composites in Wind would not be possible without the expertise and support of our supplier partners,” said Offner. They include 3A, 3M, Airtech Advanced Materials Group, Ashland Performance Materials, Chem-Trend, Chomarat, Gurit, ITW Polymers Sealants – North America, Owens Corning, Polynt Composites USA, Inc., Mankiewicz, PRO-SET, SikaAxson, and Vectorply.

This is the second of four schools in advanced composites being presented this year by Composites One and IACMI. Following this event are these workshops (check compositesone.com for dates and registration details):

- Process & Advanced Materials Workshop – West Lafayette, Indiana

- Process & Automotive Market Advances in Composites – Detroit, Michigan

Space is limited. Sign up here.

Filed Under: Blades, News