Editor’s Note: Des-Case, a developer of contamination control products for industrial lubricants, recently released a whitepaper titled “Taking fluid cleanliness to the next level with permanent offline filtration.” In it, the company discusses the benefits of permanent offline filtration solutions over portable units. The introduction of the article is presented here. Download the whitepaper at this link.

Introduction

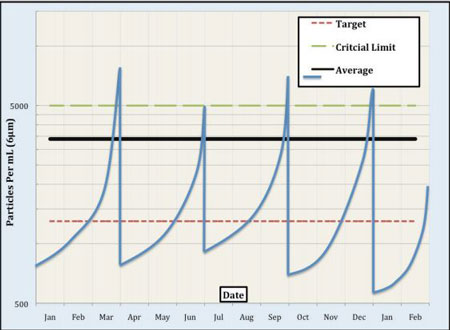

Figure 1: “The target cleanliness for the gearbox is only met for a short time after filtration. With a target of 19/17/14, the 6m particle concentration should be below 1300 particle/mL. With quarterly filtration, the average particle concentration in this size range is 3,900 which corresponds to a particle count of 20/18/15. While this only represents an increase of one ISO code, the actual number of particles is almost 3 times the target. With a permanently installed filtration system, this system would likely be cleaner than the target.”

In recent years, portable filtration units, often referred to as filter carts, have become a common tool in the lubrication professional’s arsenal. Increasing demand for these systems has led to the development of a wide range of new products and driven down prices, which is a good thing. When filter carts first came onto the scene they were primarily used by service providers for decontaminating large systems. These early models were typically designed for low viscosity oils in large volume systems and were on the expensive side, making them unsuitable or impractical for many applications.

As awareness of precision lubrication and contamination control grew and maintenance programs began utilizing these services more often, many began purchasing their own filter carts, but usually only one unit for an entire plant. Very quickly, plants began to realize they were wasting time and money by switching products, so they started dedicating filter carts for particular lubricants in order to avoid flushing requirements and to increase their capacity to decontaminate systems. Now, the next evolution in offline filtration is permanently installed kidney loop systems. While portable systems will always have their place, permanent solutions offer several benefits including better average fluid cleanliness and far fewer man-hours.

Ideally, portable filtration should be used as a “condition-based” activity, providing a means to decontaminate systems when the particle count exceeds an acceptable limit. Having this option offers the ability to decontaminate any system in a plant when many of those systems can’t justify their own dedicated filtration system. These systems provide additional value with the inclusion of water absorbing filters, offering the ability to remove water from small systems as well. The potential problem with portable filtration comes with the required resources for moving and setting up the system. If the filter cart was used with another lubricant previously, there are also flushing requirements and possibly filter changes as well. The time requirements may be minimized by properly fitting the reservoirs with quick connect fittings, but it is still a significant drain on resources. This is not really a problem for on-demand or condition-based filtration, but when the task is performed regularly, such as every month or every week, this time can really add up.

An additional consideration is that periodic filtration is potentially unable to maintain target cleanliness levels. It may be that fluid cleanliness targets are only met for a short period after filtration and then remain unacceptably high until the next scheduled filtration task. The chart in Figure 1 illustrates this potential problem in a gearbox for which the target particle count is 19/17/14.

To continue reading, download the whitepaper at this link.

Des-Case Corporation

descase.com/

Filed Under: Components, Filters, Lubricants, News