The Air Blades are assembled in such a way to allow field configurability of three, five, or seven blades letting the installer optimize a turbine for the wind regime present at the installation site.

Although small-wind systems involve a significant initial investment, they can be competitive with conventional energy sources when accounting for a lifetime of reduced utility costs. As fuel costs escalate, small wind systems become more competitive.

The cost of buying and installing a small wind energy system typically ranges from about $4,000 to 7,000/kW for a grid-connected installation, less than half the cost of a similar solar electric system. The length of the payback period (or, the time it takes to “break even”) depends on the selected system, the wind resource at the site, the power provider’s electricity rates, and the available financing and incentives. Small wind owners with strong average wind speeds who can take advantage of rebate programs can usually recoup investments within 15 years.

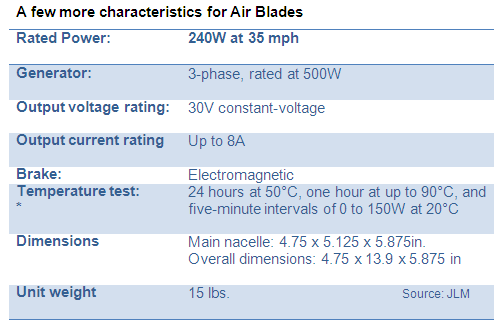

The system that takes advantage of these conditions is called Air Blades. It was designed using analytical, computational fluid dynamics, and empirical techniques. The blades were tested at various wind speeds to provide optimal cut-in speeds without compromising the power output at higher wind speeds. Air Blades are manufactured using high-tech composite materials to provide stiffness at a low weight.

The Air Blades are assembled in such a way to allow field configurability of three, five, or seven blades letting the installer optimize a turbine for the wind regime present at the installation site. What’s more, developer JLM has implemented a gearing mechanism for using an array of these turbines.

A few other features include the SmartGearbox which implements an entire gearing mechanism using smart micro-controller technology. The nacelle contains all necessary hardware and software to convert the wind’s energy to electrical power with the output voltage holding steady at 30V and a current ranging from 0 to 10A. In addition, the nacelle houses the BreezeBox and BrakeBox modules.

The metal housing is zinc plated, epoxy dipped and powder-coated, providing a NEMA-4 (IP65) housing that is guaranteed for 15 years. The AutoFurl function activates at 35 mph for the seven-blade rotor and is built into the nacelle.

Since the Small Wind Certification Council (SWCC) does not recognize the array configuration, qualifying our wind turbines using a single string inverter would be impossible. On the other hand, owners are excited to use multiple wind turbines, configured in an array, to produce a substantial amount of energy.

To provide maximum flexibility in configuration and installation of our arrayed wind turbine technology, each Zefr wind turbine interfaces with its own dedicated micro-inverter. The micro-inverter, while common in the PV Solar industry, has never been used in wind turbines due to complex technology barriers. JLM’s Zefr is the first wind turbine in the world that has been successfully interfaced with a micro-inverter. The micro-inverters used by JLM are UL1741 / IEEE1547 certified and are warrantied for 5 years. In addition, they are compatible with 208V, 3-phase or 240V, single phase grid configurations.

JLM

Filed Under: Financing, News