To ensure a wind turbine is designed to meet each country’s safety codes, regulations should be compiled in a safety design manual, much like this example, called “Engineering EHS Turbine Design Manual.”

Michael Hughes, CIH, CSP | Global Head of EHS for Onshore Wind

Siemens Energy, Inc.

A commitment to safety underpins the design of a wind turbine, while designers focus on transportation, practicability, cost, and functionality. Balancing these design goals must occur in a manner that does not compromise the safety of those who manufacture, install, or service the turbine over its lifecycle.

The best way to control operational risk is to eliminate hazards during a turbine’s design or planning stage. Safe design integrates hazard identification, risk assessment, and control methods early in development to eliminate or minimize risks to the long-term integrity of the turbine.

The first challenge is to ensure a turbine design meets or exceeds all Environmental, Health, and Safety (EHS) requirements applicable to all countries where installation is planned.

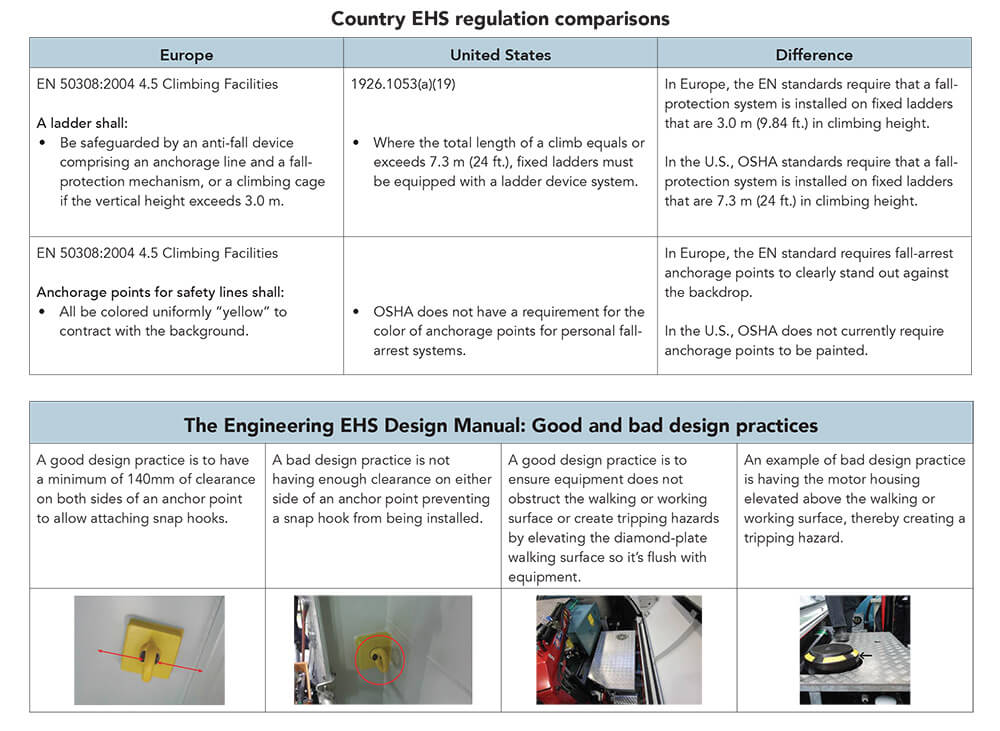

This is often an issue because turbine designers aren’t always familiar with all locations their turbines may be installed. The design team’s location determines the baseline design criteria of the turbine. For example, when a team is located in Denmark, the EN standards serve as the baseline design reference. When teams are in the United States, OSHA or ANSI standards provide the reference.

If these baseline references are not adjusted to the countries where the turbine is eventually installed, it may be out of compliance with regulatory requirements in those locations.

Hundreds of EHS regulations may add to the challenge, depending on the country. Therefore, it’s important to identify all EHS regulations applicable to the design before development begins. Ideally, the regulations and internal requirements should be compiled in a manual, much like the one displayed, called Engineering EHS Turbine Design Manual.

This manual can include supporting information, such as pictures of best practices, mistakes that have led to retrofits, and other safety issues. Clarity and consistency are also keys to the success of this manual. It’s important the EHS regulations are filtered for the applicable requirements based on where the turbines will be installed, and that this information is presented in a manner that’s easily understood by the design team. Consistent updates and ongoing reviews are necessary to ensure the manual incorporates new regulatory changes and that the changes are properly communicated to the design team.

This engineer is performing a virtual or 3D Concept Design Risk Assessment. This is where a consultant validates that a turbine design meets the regulatory requirements of a specific country.

Once a team has a firm understanding of the EHS regulations, then turbine designing can begin for the target market. After completing a design model, it’s important to perform a virtual or 3D Concept Design Risk Assessment. This is where the Engineering EHS organization, and either an EHS representative from the target market country or an EHS consultant, validates that the turbine design meets the regulatory requirements. This person also ensures there’s sufficient clearance to perform the many installation and maintenance tasks necessary at a wind site.

For instance, the design of an electrical panel may meet the regulatory requirements for work clearances, but its position in the nacelle might obstruct a technician’s ability to complete routine component changes. A virtual walkthrough of the turbine can simulate actual work positions and limitations where alternatives may prove effective and can be modeled. This ensures selecting the most effective solution and provides for a reliable turbine design that meets all EHS regulations.

After the Concept Design Risk Assessment is completed and deemed sufficient, a Detailed Design Risk Assessment should follow. This assessment is completed during the prototype phase and provides an opportunity for the design team, including representatives from the EHS organization, to physically validate that all EHS risks are accounted for and are not an issue. The team should also assess the effectiveness of the controls and mitigations, and make necessary adjustments before a turbine goes into serial production.

This final risk assessment ensures the production of a fully compliant turbine with the least likelihood of risk throughout its lifecycle. The goal is to remain committed to safety in the design and production of turbines, while delivering a machine that provides maximum output with the latest advances in design expertise and technology.

Filed Under: Projects, Safety, Turbines

The referenced standard 1926.1053(a)(19) is a construction standard. That standard would apply while the wind turbine was being erected. When in operation, during service work, etc., the 1910.27 standard would apply. The 1910 and the 1926 are very different regulations.