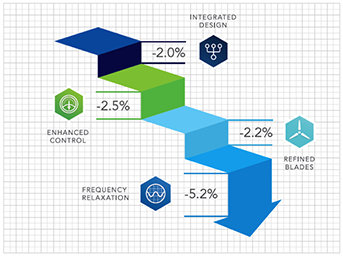

This chart presents a levelized cost of energy savings from Project FORCE for a typical offshore site.

DNV GL’s recently launched project FORCE (For Reduced Cost of Energy) has identified potential savings of at least 10% of the cost of offshore wind energy, if an integrated approach to four market-ready technologies is adopted.

Project FORCE was set up to explore how the idea of “integrated design” could reduce offshore wind costs when applied to the wind turbine and its supporting structure for a typical project. Twenty-five DNV GL engineers from disciplines including cost modelling, offshore load calculations, blade design, controller design, and structural design were brought together to work on the problem. Through the combination of four technologies (integrated design, relaxation of frequency constraints, enhanced control systems, and slender, faster blades) aggregate cost savings of over €1Bn in NPV terms could be achieved over the next decade.

“The cost savings identified by the FORCE team could be exploited by industry right now,” says RV Ahilan, executive vice president for renewables advisory at DNV GL. “The problem is the misalignment between the design-risk of the changes needed and the cost-reduction reward delivered by those changes. Whilst the former mostly lies with the wind turbine manufacturer, the latter benefits the complete offshore wind asset. The technology is there – we now need to smash down the commercial barriers to make it happen.”

In order to remove these barriers, DNV GL believes a rapid maturation of industry practice is needed via an integrated and collaborative approach to design, engineering, and procurement.

“Ultimately healthy levels of collaboration are as important as healthy levels of competition,” says Tim Camp, head of turbine engineering. “Whilst we have made significant progress on improving supply chain competition over the last few years, it is now time that we start acting like a mature industry – embracing both collaboration and integration.”

DNV GL

www.dnvgl.com/energy.

Filed Under: Financing, News, Offshore wind