By Leland Teschler, Executive Editor

Design World

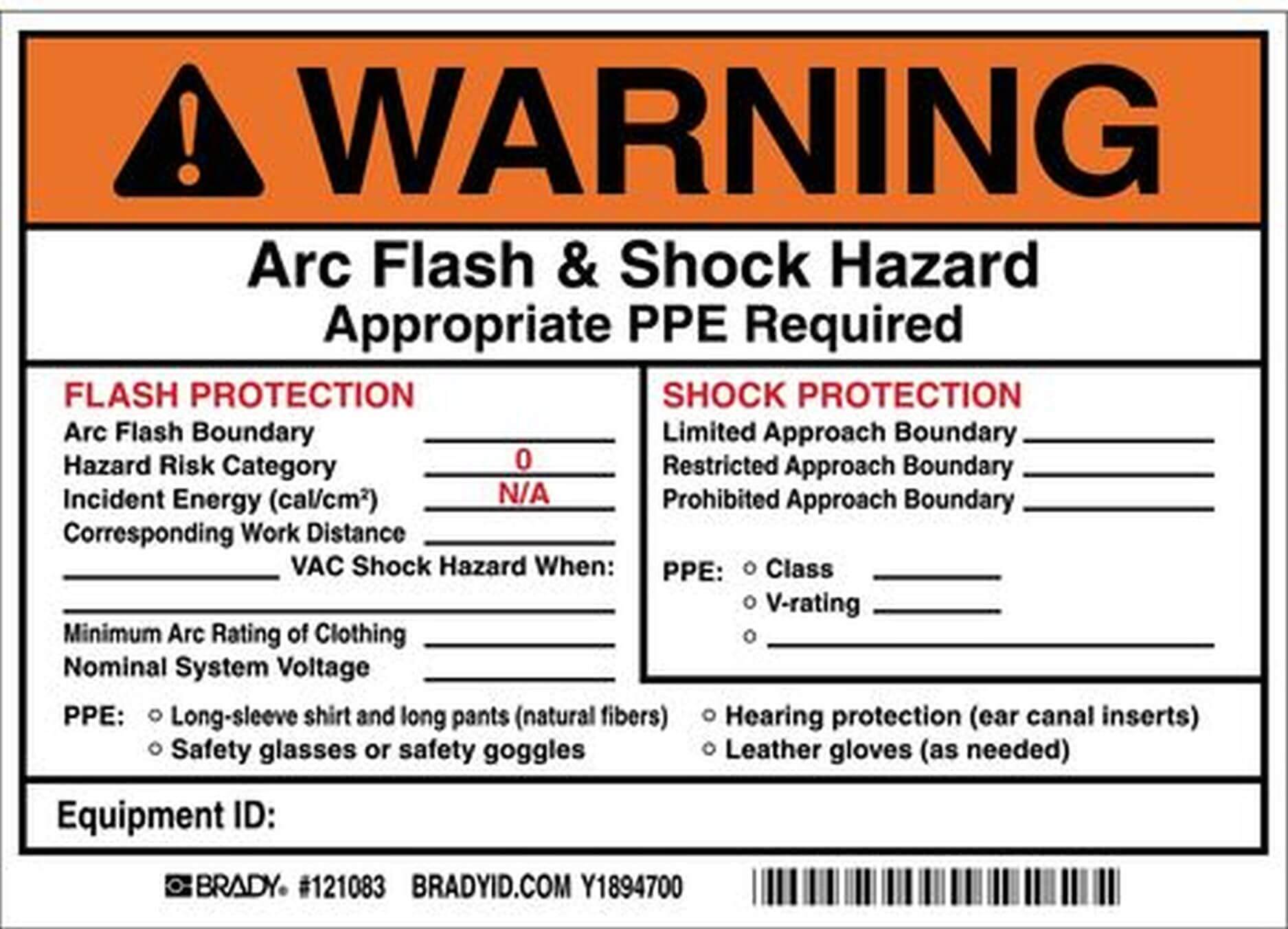

A typical arc flash hazard label, this one from Brady (bradyid.com). Label information is verified by conducting arc flash hazard studies.

Electrical safety instructor Redwood Kardon tells this story about arc flash problems on wind farms: “Five years ago, when I would go out to a facility, they would say, ‘Oh, we’re going to start (arc flash analysis),’ or, ‘We’ve hired an engineer.’ They didn’t have arc flash labels in place. Now, most facilities have arc flash labeling but the workers don’t know what the labels are for, and they aren’t trained in how to interpret them.”

An inability to understand an arc flash label can be a potentially lethal shortcoming. Viewing a few of the numerous YouTube videos of actual arc flash events generally gives viewers a healthy respect for these mishaps.

An arc flash, of course, is the conductive plasma that can arise because of a short between high-voltage and high-current conductors such as bus bars. The massive energy discharge vaporizes the copper conductors and causes an explosive volumetric increase that comprises the arc blast. The fiery explosion can destroy everything close by, creating deadly shrapnel.

One of the primary defenses against arc flash injuries takes the form of warning labels. The National Electrical Code dictates that warning labels are displayed anywhere there is an arc flash hazard. The warning label must spell out the flash protection boundary, the incident energy level, and the kind of personal protective equipment (PPE) needed for safely working in the area.

But labels offer little protection if workers fail to understand them. “People get confused about the protection boundaries mentioned in the labels,” says Kardon, who also founded an arc flash teaching company called the Code Check Institute.

Arc flash labels are one of the end results to come out of a formal arc flash hazard analysis. In a hazard analysis, data is collected about the physical arrangement of the facility’s power distribution system. The data includes the arrangement of components on a one-line drawing. (A one-line drawing gets its name from the fact that it is a schematic representing the three phases of a three-phase system with a single line.) Also included are the lengths and cross-sectional area of all cables.

With the data collected, next comes a short-circuit analysis followed by a coordination study. A short-circuit analysis establishes the right interrupt ratings on protective switchgear. It is meant to head off the possibility of an electrical fault exceeding the interrupt rating of the device that is supposed to stop it. A coordination study ensures faults are interrupted by the protective device nearest to them. It also helps avoid nuisance trip-outs from transformer inrush or motor starting procedures.

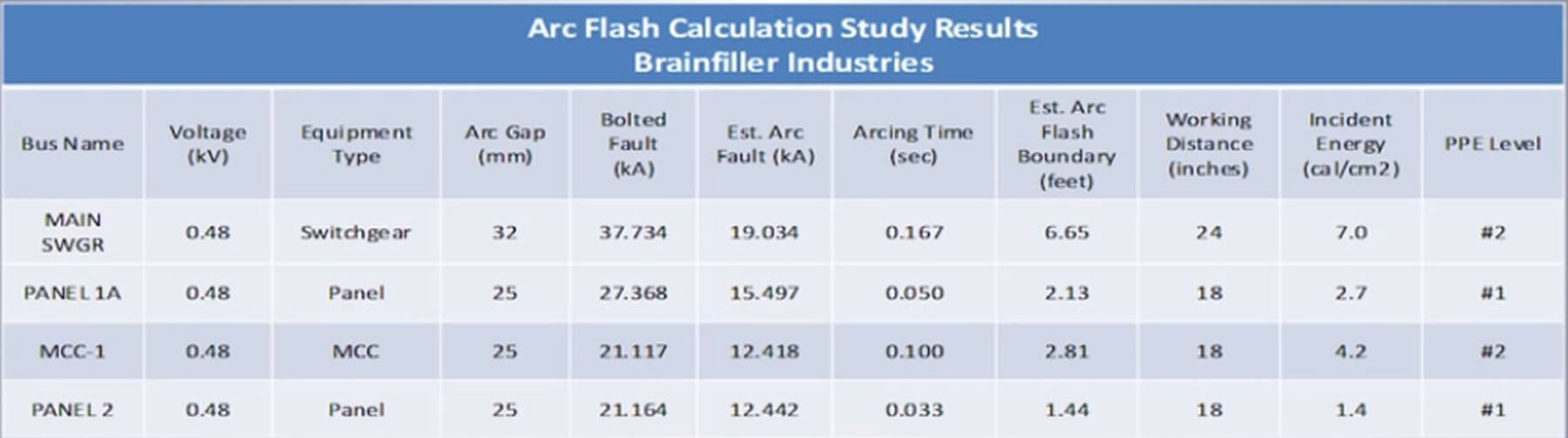

An example of an arc flash study comes from Brainfiller Inc. Engineers would focus on the highest incident energies and make sure they are below the arc rating used for the equipment in question.

Data from these studies get fed into equations described by either NFPA 70E-2000 or IEEE Standard 1584. These equations will produce the flash protection boundary distances and determine the incident energy and thus the PPE for personnel in the vicinity.

Wind-farm operators who conduct arc flash studies often do so at the direction of OSHA. “Some states administer their own program. But OSHA says that you must have a workplace free from recognized hazards,” says Jim Phillips, a P.E. who specializes in electrical power systems and founded an electrical training company called Brainfiller Inc. “OSHA references what’s called an industry consensus standard. The one that is used most widely is a standard called NFPA 70E. It is 70E that calls for an arc flash study.”

Several factors complicate the procedures surrounding arc flash analysis. One of the more fundamental issues is the question of who is qualified to do the analysis.

“That’s controversial,” says Phillips, who also chairs the committee updating the IEEE 1584 standard for performing arc flash hazard calculations. “When we wrote the first draft of the IEEE 1584 standard, we included wording to the effect that only a licensed P.E. could perform the study. But we were practically tossed out of the room by people who weren’t P.E.s. So we had to backpedal a bit.

There are different levels of personal protective equipment (PPE) proscribed for use during electrical work depending on the expected arc energies. This technician is working on a transformer in a nacelle. (Image: Code Check Institute)

The standard now states the analysis must be performed by somebody who is trained and knowledgeable, but it has to be done either by or under the direction of a licensed P.E. Of course, people who are not P.E.s just ignore that.”

Consequently, the quality of arc flash studies can vary. “I have been contacted by many people asking about how to perform these studies,” says Phillips. “The questions they often ask are so fundamental, it makes you think they have no business doing one. Technically, there is no hard and fast guidance on who can perform arc flash studies, but individual state engineering licensing boards should probably call the shots.”

The end result of an arc flash analysis is a set of warning labels designed to both caution workers about arc flash dangers and provide guidance about how close workers with specified levels of protective clothing can approach. One problem is that arc flash labels can be confusing to the untrained eye.

“They’re labels with a lot of details,” says Phillips. “The label will spell out something called an arc flash boundary. I don’t want to call that boundary a safe distance, but it is a safer distance for unprotected people to stay behind. The label also designates the kind of protection to wear, and it can do so in different ways. It can use either the calculated incident energy, which is basically the severity of the arc flash, or it can use what’s called a category scheme, which dictates certain levels of protection. Basically, the label is for the worker to look at and recognize, ‘Oh, unprotected people should stay back X distance. And if I’m doing the work, I have to wear X type of PPE.’”

New arc flash calculations

A further complication for those in the process of setting arc flash limits is that the calculations used in the IEEE 1584 arc flash standard are about to change. Expectations are that revisions to IEEE 1584 will be out by the end of the year.

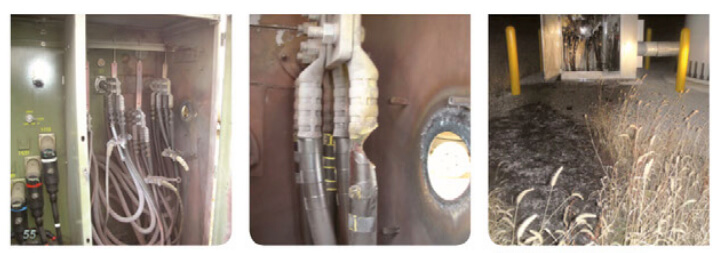

The aftermath of an arc flash event in a switchgear enclosure of a wind turbine. (Image: Code Check Institute)

“I often get asked what changed. The easier question is, What didn’t change? The title is still the same. Everything else has changed, top to bottom,” Phillips. For example, the equations are completely different. There’s the first round of calculations and then there’s a whole series of adjustments for your specific voltage. It’s a really complex calculation.”

However, the software normally used for running arc flash calculations will be updated as soon as the new standard emerges. “Each of the major software companies have representatives on the committee,” says Phillips. “As we’ve been developing the equations, they have been getting geared up. They’re just waiting for somebody to say, ‘Go,’ and all the new software will be out.”

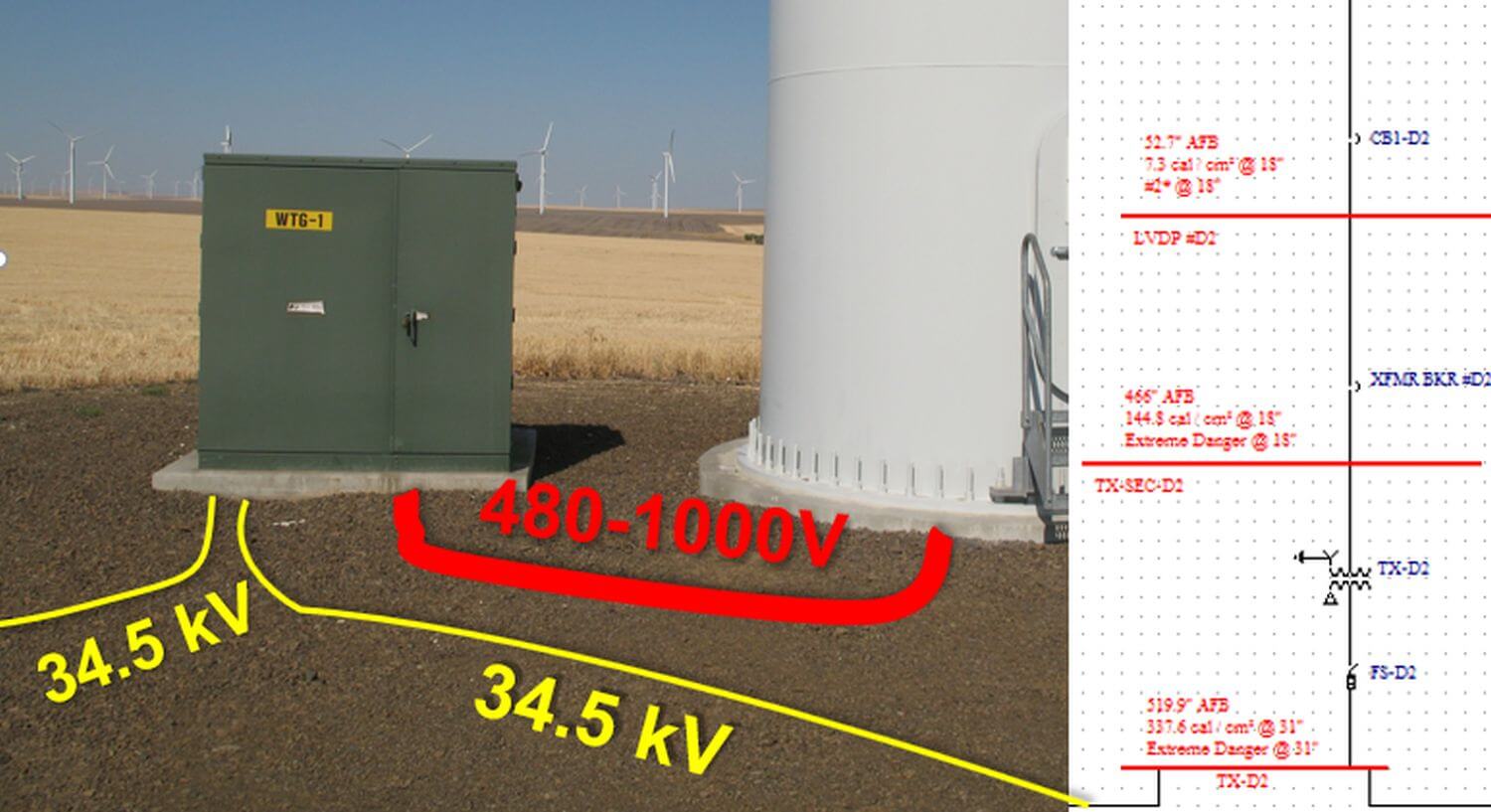

An example of a one-line drawing used in an arc flash study of a wind turbine. (Image: Code Check Institute)

One change that is likely to impact wind farms is a move to have the standard cover a wider range of enclosure sizes. The original 1584 spec only mentioned two enclosure sizes. “The new standard covers a lot more choices for enclosure sizes and adjustments for enclosure sizes,” says Phillips.

Also changing is something called the 85% rule. “The 85% rule is going away,” says Phillips. This rule pertained to calculations of arcing short-circuit current and under what circumstances estimates of its intensity could be relaxed somewhat for calculations of fault clearing time. Also gone from the revised standard are provisions for 125 kV-A transformers. “The thought was if you’re down to 208 V and have a limited short circuit current, the arc would be less likely to sustain and be substantial. We found in the lab that this is not quite the case so that rule is being changed dramatically,” says Phillips.

Those are the highlights of the new standard. There are other aspects of it that may yet change before its release at the end of the year.

Filed Under: News, Safety

Good article, but the new format is not. The text is hard to read. Darken it a little and things will be fine.