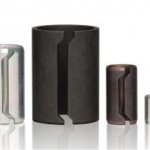

A recent brochure from Spirol Corp. covers many uses for coiled spring pins and the company’s many other specialty fasteners. The pins use a 2¼ coil cross-section to make them self-retaining pins that compress when installed into a host component. The manufacturer says they are the only pins with uniform strength and flexibility after insertion. The pins come in three “duties” so a designer can choose a best combination of strength, flexibility, and diameter to suit different host materials and application requirements. The shock-absorbing design dampens forces and vibration to prevent hole damage and prolong assembly life. Coiled pins have square, burr-free ends and lower insertion forces than other pins, which make them well suited for automated assembly systems. The company also manufacturers a dozen other fastening devices such as slotted spring pins, solid pins and drive studs, and rolled tubular components.

A recent brochure from Spirol Corp. covers many uses for coiled spring pins and the company’s many other specialty fasteners. The pins use a 2¼ coil cross-section to make them self-retaining pins that compress when installed into a host component. The manufacturer says they are the only pins with uniform strength and flexibility after insertion. The pins come in three “duties” so a designer can choose a best combination of strength, flexibility, and diameter to suit different host materials and application requirements. The shock-absorbing design dampens forces and vibration to prevent hole damage and prolong assembly life. Coiled pins have square, burr-free ends and lower insertion forces than other pins, which make them well suited for automated assembly systems. The company also manufacturers a dozen other fastening devices such as slotted spring pins, solid pins and drive studs, and rolled tubular components.

The pins use a 2¼ coil cross-section to make them self-retaining pins that compress when installed into a host component. The company says they are the only pins with uniform strength and flexibility after insertion.

The company suggests those seeking a custom fastener might be interested in the its Optimal Application Engineering program. This is a five step procedure for designing and delivering the fastener more useful than one off the shelf. Step one, with the client, defines product performance, assembly, and commercial objectives. This includes gathering sample components, the drawings of the individual components, and assembly-level drawings. This stage also defines commercial objectives such as a target product cost, product packaging and labeling, and delivery requirements.

Step two calls for a comprehensive engineering evaluation after gathering product, assembly, and manufacturing objectives. Spirol says its application engineers can help find a best solution for the particular application.

In step three, the company provides a formal technical and commercial proposal, including prototypes for evaluation in the client assembly. The proposal will detail other products considered for the application, and why the recommended part is the best design.

Step four: When installation equipment is involved, Spirol can design a fixture to hold and align components during insertion. The company also builds, tests, installs, and certifies the machine, and educates operators and maintenance personnel.

Dowel bushings and spring dowels, other company products, can maintain alignment and are used to locate components with respect to each other. These roll-formed, hollow alignment dowels have lead-in chamfers that facilitate insertion into the holes of both mating components.

In step five, the company plans production to meet client-delivery requirements and will ship certified products anywhere in the world. Spirol says it provides a formal technical and commercial proposal, including prototypes for evaluation in an assembly. The proposal will detail other products that were considered for the application, and ultimately why the recommended part is the optimum solution. The brochure is available at the URL below.

Spirol International Corp.

http://www.spirol.com/library/main_catalogs/SPIROL_Corporate_Brochure_us.pdf

Filed Under: Construction, News