A Dirt-Gate reservoir breather keeps reservoir air at a low relative humidity, and more importantly, at a lower dew point temperature than ambient temperature. Eaton says 80% of hydraulic system problems are related to inadequate contamination control.

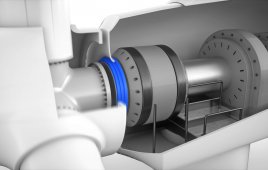

Eaton’s Vickers Filters handle flows to 450 gpm and pressures to 6,090 psi. Bypass valves, pressure drop indicators, and media grades facilitate filter installation and provide needed system cleanliness. A closer look at reservoir vent filters shows its useful features.

These sport visual indicators and corrosion-resistant housings. In addition to particle control, these filters also feature water and moisture control needed in harsh wind-turbine environs.

The Dirt-Gate Reservoir Breather, in particular, filters out airborne particles before they contaminate the oil. Hydraulic reservoirs “breathe” air in and out as the oil level rises and falls. This air contains water and particles that are destructive to machinery over long periods. The H20-Gate Reservoir Breather filters out particles and moisture before they contaminate oil.

During an oil tank’s “inhalation” cycle, the H2O-Gate proprietary media blocks water vapor from entering the reservoir. During “exhalation”, the media lets moisture in the reservoir air exit. Moisture is carried off the media by the exiting air, restoring the media’s water barrier capacity. Eaton says the moisture barrier mechanism is unaffected by the amount of moisture exposure.

The company adds that it is committed to contamination control and superior performance of its products. To prove it, the company will extend the standard warranty by three years of all Vickers products used in a system protected by Vickers filters when they are applied consistently to principles of the company’s PAM program.

Filed Under: Hydraulics