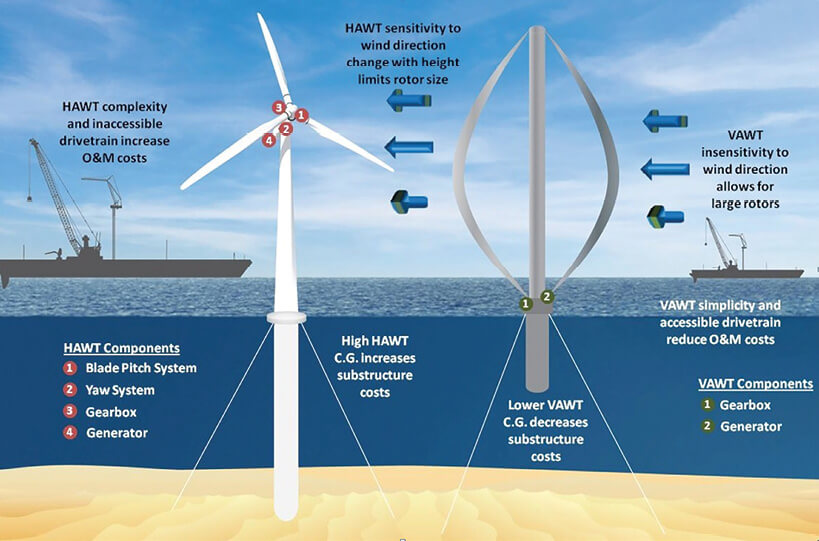

There are still many advantages to Vertical Axis Wind Turbines (VAWTs) over the conventional three-blade designs, especially when considering offshore duty. Engineers at Sandia National Labs are working on models for an offshore VAWT and offered this mid-project report.

“The goal of the project is to advance the rotor technology of large offshore vertical axis wind turbine from concept to lab-scale prototype stage through four major research thrusts,” says project supervisor D. Todd Griffith. The steps include:

- Innovative aeroelastic rotor conceptual design

- Deep-water system design and cost analysis

- Rotor material and manufacturing strategies, and

- Subscale rotor prototype design and testing.

The project aims to capitalize on the VAWT advantages for offshore cost reductions while addressing the key VAWT technical, design, and manufacturing challenges.

The overarching project objective, says Griffith, is to investigate the feasibility of the VAWT architecture for very large-scale deployment in the offshore environment. “The most critical barrier to offshore wind, its high cost of energy (COE), is specifically targeted with the overall goal of achieving a 20% reduction in COE by applying VAWT rotor technology,” he says. His team will achieve this goal by

- Developing innovative VAWT rotor designs that enable reliable, cost-effective, and easily manufactured rotors for deep-water offshore machines at the 10 to 20-MW scale;

- Demonstrating the potential for greater than 20% reduction in COE for a deep-water, floating VAWT system compared to current shallow-water horizontal-axis wind turbine (HAWT) systems;

- Developing manufacturing techniques, certification test methods, and a commercialization plan for offshore VAWT rotors to accelerate deployment; and

- Testing in a wind tunnel and combined wind-wave tank, a proof-of-concept subscale, deep-water floating offshore wind turbine employing a VAWT rotor.

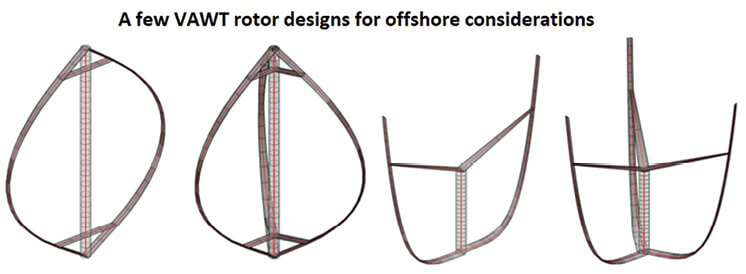

An initial research focus has been VAWT code development and code coupling, and design studies for VAWT rotor and floating platform. The figure above shows several rotor configurations that Griffith’s team has analyzed. In addition, we have performed structural dynamics and resonance impact analyses to investigate the effect different support structures and number of blades on VAWT vibratory response and vibratory loading, which are key design drivers. Future work includes plans for detailed system design studies and subscale testing.

Filed Under: Featured, News, Offshore wind