Editor’s note: This article, from ABB Review: Corporate Technical Journal, should be of interest to all power producers because the right electric bus, battery, and charging scheme has potential to take dirty diesels out of city centers and create demand for more electric power. DOE reports that power consumption increased less than 1% in 2015. Ideally, the power consumed from an electrical transport system would be generated by renewable energy, and preferably wind generated power.

If you thought charging electric vehicles was all about fiddling with charger cables and long and unproductive periods, think again. ABB and partners has developed an electric bus that charges in 15 sec, provides many seats, and runs efficiently. The TOSA bus’ secret is an overhead high-power charger that makes contact when it pulls into a stop. There it tops off its batteries while passengers get on and off.

Bruce Warner and Olivier Augé, ABB Sécheron S.A., Geneva, Switzerland

bruce.warner@ch.abb.com, olivier.auge@ch.abb.com

Andreas Moglestue, ABB Review, Zurich, Switzerland

andreas.moglestue@ch.abb.com

The world is becoming increasingly urban. In 2008, for the first time in the history of humanity, more than half the planet’s population lived in cities. Cities bring with them many challenges, not least of which is the efficient organization of transportation. To avert gridlock and reduce pollution, planners across the globe encourage the use of public transportation.

The TOSA demonstration bus sports numerous environmental bonuses. For instance, it is silent, entirely emissions free, uses long-life and small batteries while the visual clutter of overhead lines and pylons often a barrier to trolleybus acceptance is made a thing of the past. The system is inherently safe because the overhead connectors are only energized when they are engaged, and the electromagnetic fields associated with inductive charging concepts are avoided.

Public transportation in cities can take numerous forms, but what they all have in common is that they require transmitting energy from a fixed supply to a moving vehicle. This transmission takes one of two forms: Power is either stored on the vehicle, usually as diesel fuel, or transmitted electrically which requires a continuous contact system as is common on metros, trams and trolley buses.

The latter transportation forms are typically seen on heavily used corridors where the significant infrastructural investment is easier to justify. The former solution is typical for more lightly patronized corridors where lower startup costs permit routes to be created or modified more flexibly. This status quo has worked for many decades, but how much longer can it do so? Rising fuel prices and the reduced acceptability of noise and pollution have led manufacturers and operators to think about alternatives to diesels for powering buses. Solutions implemented to varying degrees include less conventional fuels (such as natural gas) and adopting alternative propulsion concepts, for example hybrid buses, battery buses and trolleybuses.

A feature shared by the latter three is that they use electric motors, permitting energy to be recovered when the bus brakes, creating an opportunity to reduce energy waste. Recovering energy is not, however, strictly the same as reusing it. Hybrid and battery vehicles use batteries to bridge the mismatch between supply and demand, whereas in the case of trolleybuses this can be handled by the substations and grid.

The limitations of battery buses

Despite considerable progress in battery technology, their energy density is orders of magnitude lower than that of diesel fuel 1. The weight that batteries add to the bus reflects negatively on its energy footprint, and the space they require can reduce passenger-carrying capacity. This can be countered by using fewer batteries (and recharging them more often) but such additional visits to the charging station come with a time and productivity penalty.

The trolleybus trumps these disadvantages. The absence of a larger on-board energy store reduces vehicle weight and permits better acceleration using less energy. The disadvantage, however, lies (or rather hangs) in the overhead lines. These are costly to install and maintain and are not always welcome due to their visual impact. Is there a way to keep a battery bus on the road without resorting to either large, heavy, and space-consuming energy storage or to frequently take the bus out of service for a deep and full recharge?

Transport passengers, not batteries

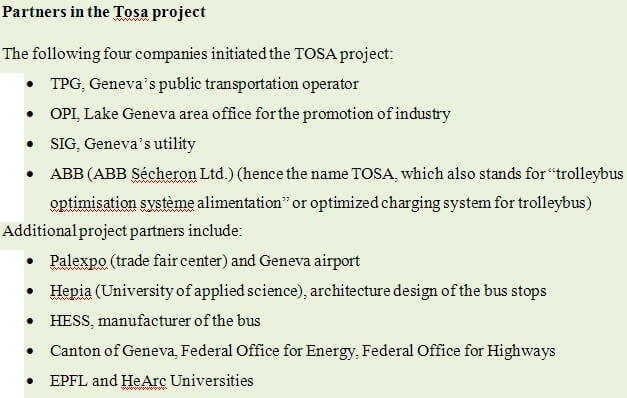

A fundamental difference between buses and automobiles is that buses follow fixed routes. The question of range, which is significant to electric cars, is reduced to the more manageable “distance to next recharging opportunity” for a bus. With buses predictably stopping at regular intervals, charging points can be located at the stops. With the bus able to top up its charge at these points, avoids need for large and heavy batteries making the vehicle lighter, more agile, more energy  efficient as well as providing more space for passengers. Furthermore, if charging time can be limited to the time the bus halts at a stop, negative effects on the schedule can be avoided. Together with partners, ABB has created the TOSA (Trolleybus Optimisation Système Alimentation or Trolleybus power system optimization) bus as a solution based on this idea.

efficient as well as providing more space for passengers. Furthermore, if charging time can be limited to the time the bus halts at a stop, negative effects on the schedule can be avoided. Together with partners, ABB has created the TOSA (Trolleybus Optimisation Système Alimentation or Trolleybus power system optimization) bus as a solution based on this idea.

Flash charging and smart grid

A high-power (400 kW for 15 s) charge of the high-power density batteries on the bus can result in load peaks affecting the local grid. A flash charger station, however, flattens the demand by charging super capacitors over a period of a few minutes while drawing a lower current from the grid. Because this current is up to one-tenth that would be the case without storage, the connection can be made with a cheaper and more readily available low-power supply. In addition, recharging the supercapacitors is timed so that they are left discharged for longer periods when the bus service is running at lower frequency. As supercapacitors are aged by higher voltages this “smart” function allows  doubling the life of the supercapacitors. With limited time available at stops (passengers typically get on and off in 15 to 25s), as little time as possible should be lost in establishing the electrical connection. The electrical connection is established in under a second. As the bus approaches a stop, the driver must oversee the safety of the passengers and pedestrians, and keep an eye on surrounding traffic. To avoid placing additional demands on the driver, the connection system is automatic.

doubling the life of the supercapacitors. With limited time available at stops (passengers typically get on and off in 15 to 25s), as little time as possible should be lost in establishing the electrical connection. The electrical connection is established in under a second. As the bus approaches a stop, the driver must oversee the safety of the passengers and pedestrians, and keep an eye on surrounding traffic. To avoid placing additional demands on the driver, the connection system is automatic.

A laser aligns the moving equipment on the bus roof with the static overhead receptacle. The connection is made as soon as the brakes are applied. By virtue of the receptacle’s height above the road surface, and furthermore by being energized only when a bus is present, this is an inherently safe solution.

Timetables define service and economics

Operating costs for a bus service are highly dependent on driver wages, schedule frequency, and fleet size. Therefore, the change from diesel to electric supply should not reduce the commercial average speed nor require an increase of the fleet size to provide the same service.

This requirement that led to the creation of two types of feeding stations along the route: The flash station and the terminal station. As described, the flash stations provide a short high-power boost of energy. However, drawing 400 kW for 15s is not sufficient to fully recharge the batteries. More prolonged charges of three to five minutes at 200 kW are thus delivered at the terminus where buses are scheduled to stop for longer periods (to give the driver a break and provide some recovery buffer in case the bus is running late). The time required for recharging at the terminus should thus not risk causing the bus to fall behind its schedule or to be unable to catch up when it running late.

The terminal charger consists of a simple 12-pole diode rectifier. This converts incoming ac supply to dc in a way similar to that used on dc railways, trams or, trolleybuses. The voltage used in this case is 500V. This solution is simple and cost effective as well as extremely reliable.

The flash charger has a more complicated but more flexible power-electronic configuration. It uses a controlled rectifier to charge the supercapacitors. This is able to regulate the amount of charging current. When the bus connects the controller closes a contact on the output side of the supercapacitors to discharge them into the bus. During operation, the batteries receive further top-up charges as the bus brakes. Rather than using a friction-based system that converts all the kinetic energy to heat, the bus’ motors can switch to generator mode and return much of this energy to the batteries. The battery charge for a typical trip is mapped in Short top up charges. The graph shows how the batteries are topped up at stops while a far larger charge is received at the terminus stop.

There is a third type of charger for the depot, where a longer charge is applied to compensate the energy required between the operating line and depot location. At the depot, the bus is plugged into a dedicated supply using a cable. A total of four buses can be connected to a depot charger which charges them sequentially.

The electrical configuration is the same as that of the terminal, a 12-pulse diode rectifier, however the power rating of the depot is 50 kW as opposed to the 200 kW of the terminal.

Renewable energy

The TOSA bus is inherently suitable for using renewable energy. In contrast to classical electric vehicles, which typically recharge when they arrive home in the evening, the bus recharges during the day and can thus make direct use of solar energy as it is produced. The ability of flash charging stations to store energy for short periods and flatten out charging peaks can also protect the system against short-term fluctuations in solar generation.

The TOSA demonstrator bus ran in public service on a short line in the Geneva, Switzerland (between the airport and the convention center PALEXPO). The demonstration ended in April 2014. The bus performed flawlessly. As a next step, the technology will be introduced on a full length bus line in Geneva.

ABB’s flash charging system for buses is competitive today, and will become more so in the future. An economic comparison of flash charging to other modes is shown in Flash charging is already competitive. The future scenario predicted is based on assumptions of rising fuel costs and CO2 duties and the diminishing costs of batteries. With diesel buses becoming increasingly less attractive, both financially and from an emissions point of view, and operators seeking an attractive modern form of transportation without having to hang wires in the street, flash charging is well situated to replace both existing trolleybus routes and urban diesel routes.

Filed Under: News