David Danielson / Asst. Sec for Energy Efficiency and Renewable Energy

The 53rd R&D 100 Awards ceremony took place recently in Las Vegas, Nevada. Going all the way back to 1963, these prestigious awards have identified and honored significant major technological developments every year.

My office at the Department of Energy (DOE), the Office of Energy Efficiency and Renewable Energy (or EERE), has a proven track record of supporting the invention and development of game changing new clean energy technologies. We invest in the nation’s top scientists, technologists, and entrepreneurs to deliver the technologies required to achieve our mission to create and sustain American leadership in the transition to a global clean energy economy. Our R&D partnerships with DOE’s National Laboratories, including through our National Lab Impact Initiative, are particularly important for achieving our bold clean energy innovation goals.

This year, nine EERE-supported technologies invented by our National Laboratories were recognized with R&D 100 Award winners in the fields of bioenergy, advanced manufacturing and vehicle technologies. I want to personally congratulate the award winners for their exciting achievements!

Editor’s note: Of the nine recognized technical developments, the one of most interest to the wind industry is that from Zeptor Corp.

High-capacity anode for rechargeable batteries – Lawrence Berkeley National Laboratory and Zeptor Corporation

Zeptor has developed an innovative silicon anode that enables battery makers to produce Lithium ion batteries that exceed 700Wh/L.

With the support of VTO, Lawrence Berkeley National Laboratory developed a silicon-based anode that can increase the capacity of a state-of-the-art lithium-ion battery by 40%. Working with Zeptor Corporation, they have incorporated this anode into a high-capacity rechargeable battery.

This is a major step-change forward in battery technology because silicon-based anodes have higher capacities than currently used graphite-based anodes. Currently, a number of major companies are testing the batteries at a pilot scale, including Microsoft, Apple, Facebook, Intel, General Motors, and BMW. GM and BMW are planning to use this technology in their next generation plug-in electric vehicles, which could substantially increase their all-electric ranges.

Zeptor’s mission is to enable the use of high-capacity material in Li-ion batteries without incurring additional manufacturing cost. Specifically, our technology enables a standard slurry process for the manufacture of silicon anodes.

Zeptor’s approach has always been about cost effective manufacturing. To that end, the core of our silicon anode technology lies in one of the simple components of the battery; the current collector. Our 3D current collectors are easily fabricated in a single-step, room temperature, atmospheric process and they allow us to make high-capacity silicon anodes with the same process as used for carbon anodes today.

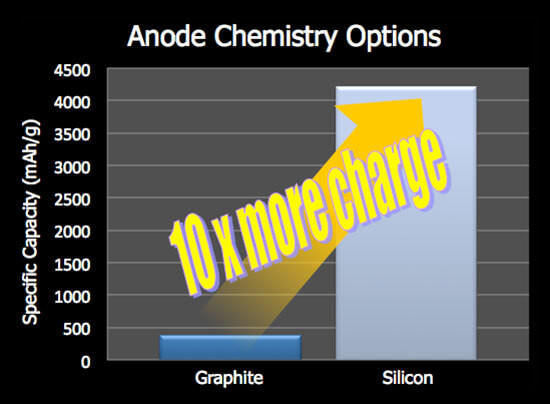

Capacity

Conventional Li-ion batteries utilize carbon graphite as the active material in the anode. Graphite has a theoretical capacity of ~370 mAh/g. By replacing graphite with silicon, the anode capacity can increase to a theoretical value of ~4,200 mAh/g. The upshot is higher energy density for anything that uses Li-ion batteries.

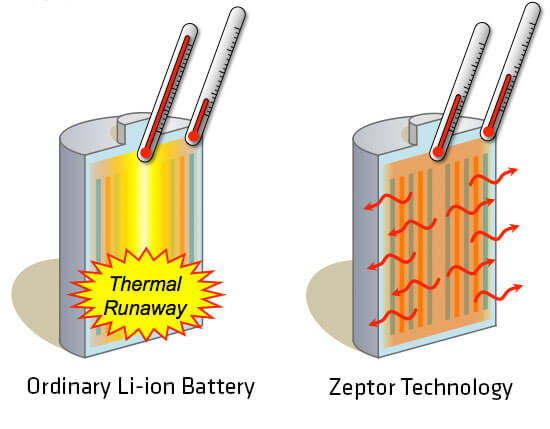

Safety

Our silicon anode has high thermal conductivity, up to ~3.7 times that of ordinary electrodes. Thus heat can more readily be drawn out of the core and transferred to the outside of the battery where it can be vented to the environment. Additionally, this gives a more timely temperature measurement for the system failsafes. Thus, Zeptor technology can play a crucial role in thermal management and reduction of thermal runaway and catastrophic explosion.

Compatibility

The anodes can be dropped into almost any current battery manufacturing line. Thus any battery producer can leapfrog to the next generation with our plug-n-play anodes.

Filed Under: Energy storage, News