About a year ago GAMESA made an important decision acquiring 50% of NEM Solutions in the effort to speed up its big-data operations and maintenance business. NEM’s entry in GAMESA with their product A.U.R.A was a long process involving intensive technical diligence in which GAMESA also tested other companies and different technologies worldwide.

Gamesa deals with vast amounts of data, turbine variables, productions, alarms, maintenance interventions work orders with the detail of material consumption, and meteorological data.

A year later, Pedro López, who was Director of Services in Gamesa for 16 years and is now a member of the board for NEM Solutions, explains that “NEM’s approach is different from that of all the other companies we have tried and assessed. NEM Solutions analyze normality and they do it well. Furthermore, not only they have excellent experience in the wind energy sector, but also in the railway sector, which we have found to be very similar to ours in terms of digitalization. The exchange of experiences between both sectors has been rewarding so far and has proven to be beneficial for both parties and for A.U.R.A’s evolution as a multi-technological product”.

Gamesa’s case is no different from any other big company in the sector. It has lots of data, a lot of knowledge, and technology is giving them the chance to take a great evolutionary leap in the way they work. Alberto Conde Mellado, founder and CEO in NEM Solutions, talks about the relationship with GAMESA in this way. “Gamesa deals with vast amounts of data, turbine variables, productions, alarms, maintenance interventions work orders with the detail of material consumption, meteorological data, etc. It is important that the data analytics we are doing, enriched with GAMESA’s technological know-how, is perfectly aligned with the business needs and the staff’s knowledge. It is not easy to find companies willing to listen to their teams and make their knowledge be part of decision-making processes. That is where NEM and the A.U.R.A technology help, we provide the interpretation of data depending on the business”

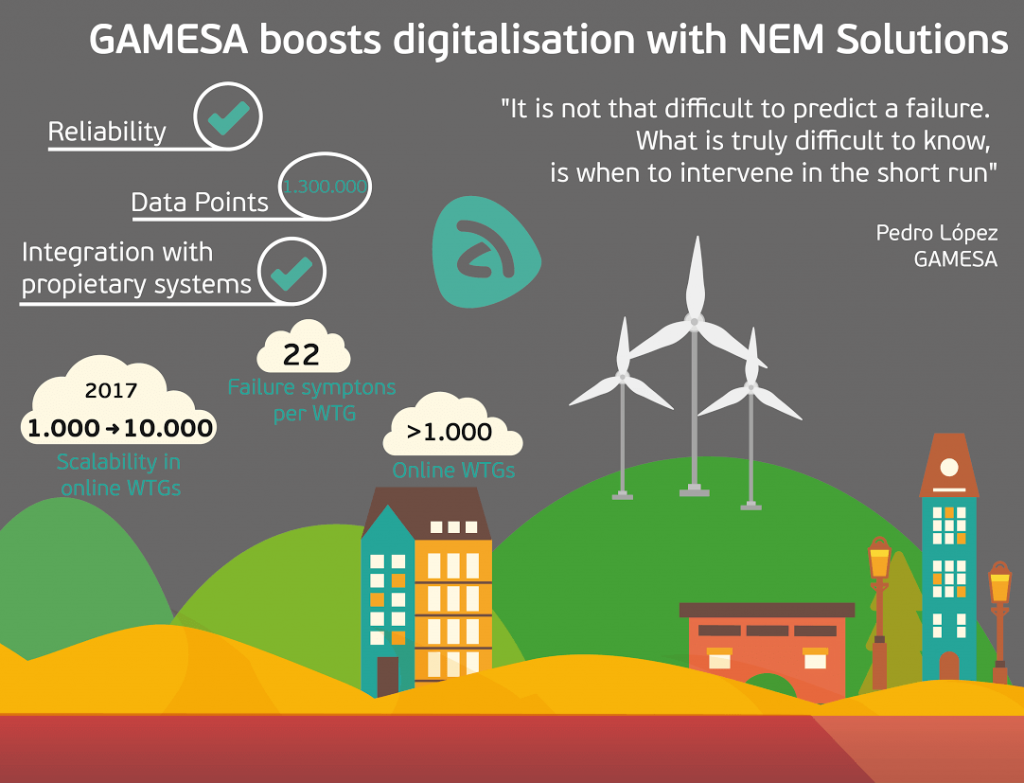

The first acid test that NEM had to overcome was a blind test on the historical SCADA data of different types of turbines resulting in a relevant success in the prediction of masked failures in the turbines without any kind of help. It was the best result received by GAMESA in a similar test with commercial solutions. BY the end of 2016, with more than 1,000 MWs already online in A.U.R.A and in the context of 14 GWs signed for the next years, GAMESA and NEM Solutions, will be able to predict with enough anticipation most of the corrective maintenance interventions.

“The truth is that the set up and commissioning of this technology and working together with NEM Solutions and their platform A.U.R.A is allowing us to move forward very quickly in the adjustment of our processes: the way in which the field information is collected and how the maintenance operations are displayed in GAMESA.

NEM Solutions is helping us with one of the critical backbones of our improvement plan, anticipating failure and prognosis”, comments Pedro López who states that “it is not that difficult to predict that a specific component will fail in a certain number of turbines next year as you can apply statistical methods associated to the operational experience. What is truly difficult is to know the best moment to intervene, anticipation in the short run − not the long run. This dynamism really improves maintenance operations and provides a differential feature”.

For this purpose, NEM relies on a thorough roadmap, based on the technology scalability and reliability, according to Mellado. “We have been working with the same objective since 2007. Competitiveness in this sector does not allow us to have a tool or software platform on which to work every day. It requires solutions that eliminate work and provide valuable information for the kind of decision making demanded in such a dynamic business as the wind energy sector,” he said.

A.U.R.A is already automatic in the generation of normality models, the rule assignment and the boundary conditions according to the type of machine, and the set up validation. It is greatly automatic as well in the maintenance and constant adjustment of the intelligence used for diagnosis. Besides, our customers count on our team for permanent support.

Filed Under: News, O&M