Kraken Robotics announced that its wholly-owned subsidiary, Kraken Robotic Systems has entered a strategic partnership with Avitas Systems, a GE Venture. The companies will integrate Autonomous Underwater Vehicles (AUVs), acoustic and laser sensor technology, and artificial intelligence-based navigation software into unique subsea inspection solutions for the offshore renewable energy and shipping industries.

AquaPix sensors are capable of providing detailed seabed images with a constant resolution that’s better than 3cm x 3cm out to a range of 300m from each side of an underwater vehicle (600m swath). It can also produce 3D bathymetric data with a resolution better than 25cm x 25cm out to full range while delivering very high depth accuracy, in compliance with IHO S44 special order requirements.

“Integrating our technologies with Avitas Systems will significantly enhance subsea asset management and provide improved safety, reduced costs, and actionable intelligence for operators,” said Karl Kenny, Kraken’s President and CEO. “We look forward to announcing our first contract during 4Q 2017.”

The announcement was made during GE’s Mind + Machines event in San Francisco, California last week.

Routine subsea inspections can be slow and costly and often include manual visual inspection with large margins of error. By using enhanced imaging technology and inspection solutions, it improves the jobs of inspectors and increase safety, accuracy, speed, cost efficiency, and asset longevity. Avitas Systems will be able to complete subsea inspection with reduced cost and time, and operational footprint.

Kraken Robotics Inc., a global provider in marine technology, brings a broad range of cost-efficient AUV technologies, such as underwater sensors, pressure tolerant batteries, thrusters, and control electronics. Avitas Systems will integrate these technologies into an autonomous subsea inspection system. The data from this inspection will be uploaded into a state-of-the-art platform that includes robust data ingestion, automatic defect recognition, predictive analytics and a cloud-based visualization portal for oil and gas and offshore energy customers.

Across industries, Avitas Systems provides autonomous inspection with robots that can target specific points on industrial assets and follow precise paths from digitized 3D models. The paths’ repeatability enables artificial intelligence-based change detection and automated defect recognition for smarter inspection scheduling based on anticipated risk.

Early detection and resolution of potential industrial issues means safer, more reliable operations and enhanced asset integrity. Working with Kraken Robotics, Avitas Systems will now be able to apply this process to underwater inspections.

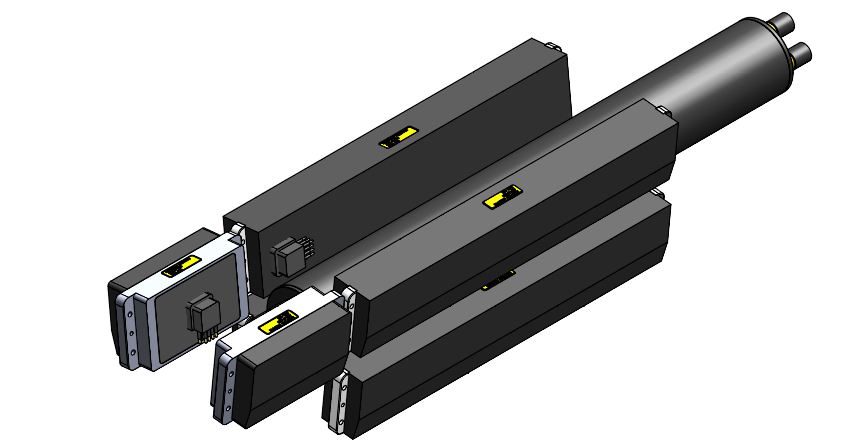

The partnership expands capabilities for inspections of ship and FPSO hulls, underwater production fields, subsea pipelines and cables and offshore wind farm assets. Kraken’s SeaVision sensor, which can flexibly attach to AUVs and Remotely Operated Vehicles (ROVs), combines laser scanning and optical imaging to provide highly detailed data for inspectors and operators. The sensor’s unprecedented colorized laser imagery better detects and characterizes corrosion, cracks, marine growth and other defects.

SeaVision’s laser scanning process can be repeated thousands of times per second to generate coordinate values for millions of points on a surface. These points then become highly accurate and intricate 3D models of subsea infrastructure.

Avitas Systems will also use sonar technology and navigational software from Kraken Robotics to optimize robots’ abilities to follow supervisory commands, track pipeline or subsea field positioning with AI-powered swim paths and identify priority areas for inspection. Kraken’s AquaPix Synthetic Aperture Sonar (SAS) technology will specifically enable 3D volumetric imaging, particularly useful for buried pipeline inspection and broader seafloor viewing.

The high-resolution images of assets’ surface contours can be inputted into the Avitas Systems cloud-based platform, where advanced algorithms fuse multiple sensor data, perform image analytics and predict actionable outcomes in real-time. The Avitas Systems platform can centralize and prioritize the inspection data by areas of interest to inspectors, which will increase efficiency.

Filed Under: News, O&M, Offshore wind, Sensors