The problem with modern utility-scale turbines is that they are so darn big. Their working stresses are high and factors of safety low. Making a turbine bigger to capture more energy provides decreasing returns because as rotor diameters are built larger, everything else in the turbine must be beefed up, from hub to foundation.

The Zond 750-kW test turbine has been working for several years with Frontier Wind’s VAriLoad system. Several Gustbuster tabs are just visible near the tip half of the blade.

But the engineers at Frontier Wind say more production can be gleaned from existing blade lengths with their active load control, a system of blade tabs that can pop out of a blade in milliseconds to take wind load off a blade almost before it is even transmitted to the blade root, not to mention the driveline. CEO Rob Giebel says he has the attention of several OEMs and expects to fly VariLoad on new turbines this year.

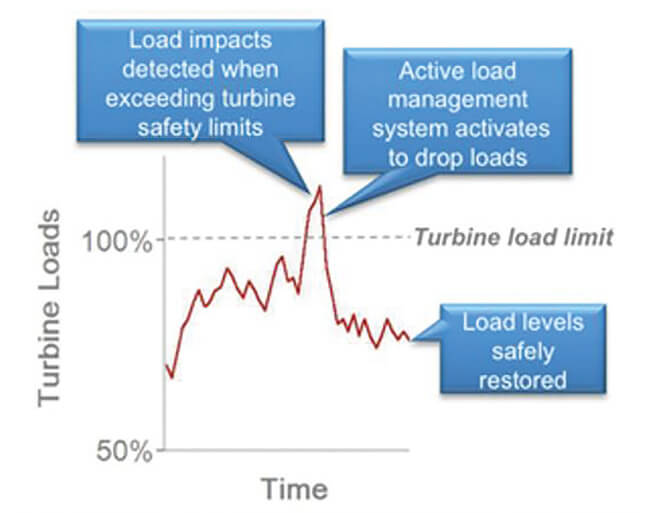

It works like this, says Giebel. “Sensors sample pressure on the suction and pressure sides of the blade at 50 times/sec and at multiple locations on each blade. When a gust or load change occurs on that blade, a series of tabs pop up. The tabs are about 1.5 to 2-in. high and about 12 in. long, depending where they are on the blade. The extended tabs separate the flow off the blade, which aerodynamically stalls the blade almost instantaneously and locally. So if the turbine has wind shear at the 12 o’clock position, only the tabs at those places on that one blade react,” he says. The other blades do not react. And when the load exits a prescribed range, the tabs are pulled back. VariLoad is agnostic to the brand of turbine, type of controller, and blade shape.

In the event loads get too big for a prolonged period, as they would during bad weather, the turbine controller pitches the blades to protect the machine as it normally would. “So the turbine controller only reacts to loads that it must react to. Often, the system will pitch to run and let Variload deal with gusts and turbulence that occurs in day-to-day operations.

“We have made several million simulations for turbines with rotors up to 150-m diameter, and under the eye of Garrard Hassan. Furthermore, we have tested it in Minnesota for three years on a Zond 750-kW wind turbine with a 48-m diameter rotor,” says Giebel. “Now we are engaged with several OEMs.” Garrad Hassan is now part of DNV GL and provides wind testing, certification, and advisory services.

During prototype testing on the Minnesota turbine, the system operated next to an identical turbine without the load control. “That let us develop all the simulations and understand what happens when mosquitoes clog the pressure port or how the system works during winter. That experience let us develop a cold-weather package. The turbine controller already knows about temperature and humidity, data that tells when ice might form on the blade and which usually shuts the turbine down for a period. The system can go into a cold-weather mode in which it deploys to break the ice off the blade. So it lets the turbine blade fly slightly longer before it turbine has to stop.”

The problem with pitch systems

Most turbines are limited by the same bottle neck – the pitch system. “The lag time – from when the load hits the blade and it is pitched to remove the load – is long

enough to let the wind that caused the load to pass the turbine. Now the blade is in the wrong place of the current wind. So instead of a system that takes three to four seconds to react, VariLoad senses the load, eliminates it, and puts the blade in the perfect flying condition in 100ms,” says Giebel.

Furthermore, a tradition system reacts so slowly that by the time the controller reacts, the load has already transmitted through the drivetrain. “It has stretched the blade, the drivetrain, and the tower. And steel never forgets. It does not heal itself,” he explains.

Another problem: The E-stop is absolutely the worst condition for a turbine because of the high-induced stresses from sudden braking. VariLoad can help reduce the e-stop frequency because an equipped turbine will tend not to throw itself upwind as much.

The overall goal is to lower the cost of energy. “Every turbine OEM has built its turbines bigger – more swept area, more energy – and the cost of power has dropped. There has been a lot of nibbling around the edges of technology changes that lower the cost of energy. For instance, many are working on smarter ones and zeros in their controller. All are working on pitch motors that will twist faster, and many are working on material science to let the blade flex differently,” he says.

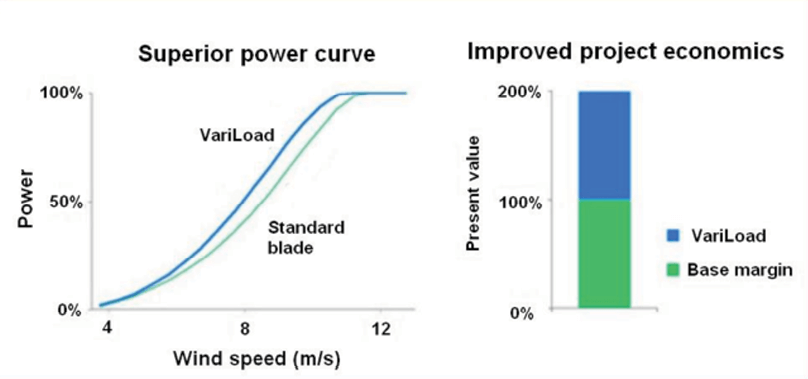

Giebel says VariLoad will lower the cost of energy. “We think it is possible to lower the cost of energy by 10 to 20%, and then scale the turbine and reduce complexity of new designs. For example, if a turbine is not putting as much load into the tower as before, it does not need as much steel. This also gives the OEM an opportunity to introduce a platform for a higher wind class using the one already designed. They will not have to spend another $70 million on a clean-sheet design that is mostly an extension of the existing family.”

Giebel’s development allows flying turbines with larger blades, or flying lower wind-class turbines in higher winds. “For instance, take a 120-m class III turbine and put it in a Class II wind, and you get 20% more energy out of the turbine.”

Another plus: lower operating noise. “Europe is more concerned about noise so we have technology that makes the tab deployment quieter and that helps with noise of the base turbine,” he says.

One thing leads to another

For a few years, the company was working on a system that adjusted blade length to capture more wind. Although it worked well in tests, capturing 92% more power than the original blades, but the system added excessive loads to a driveline. While working to reduce the high load, the company invented the tabbed system, which makes the blade extenders unnecessary.

Frontier Wind says its VAriLoad system will move a turbine’s power production curve to the left for greater megawatt-hour outputs, close to two fold according to tests.

OEMs are interested enough to have Frontier Wind engineers in Europe working to build the VariLoad feature into their blades. “The team has to design around the areas that cannot be touched or altered. Then they will run simulations and compare them to a blade on a conventional system. Even if the tabs are not optimally located, we can make up the lost performance through software,” he says.

The system has more than 100 patents and the company continues to file more. “We learned that every turbine has its own signature, like a fingerprint. Some turbines have no problems with blade loading while they have big issues with pitch loading, or with main shaft, or the tower. The work we have done lets us target the problematic loads of a specific turbine.”

Giebel says the load control system can refit onto existing blades but it is more expensive than on a new blade. His company focus is with OEMs on new construction and those companies that have control of blade design. “A couple OEMs would like to retrofit their blades because there are selling service contracts. Some components are wearing out faster than expected simply because of loads. This device can eliminate the loads and add life to some components. For instance, a drivetrain-load reduction and fewer e-stops would let gearboxes last longer.

Recent pitch systems operate almost continuously, adjusting for a best position. Some designers have asked about eliminating the pitch system if the VariLoad is used. But Giebel suggests that instead use a smaller pitch drive because it does not have to be continually twitching. It will need only pitch to run and pitch out.

Giebel is mum on costs. “That will depend on the turbine and what the OEM wants to accomplish,” he says. However, he will say to expect to see a turbine in the air with VariLoad in 2016.

Filed Under: Blades, News