Research now shows that graphene is the thinnest coating for protecting metals against corrosion. A study on this potential new use of graphene appears in ACS Nano, in which researchers say they’re finding new ways to slow or prevent corrosion on metals, such as those used with windpower technology.

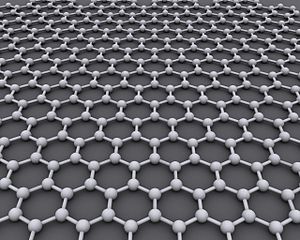

Graphene is a single layer of carbon atoms, many layers of which are in lead pencils and charcoal. It is the thinnest, strongest known material.

One approach to prevent corrosion involves coating metals with materials that shield the metal surface. Currently used materials have limitations, so the researchers decided to evaluate graphene.

Graphene is a single layer of carbon atoms, many layers of which are in lead pencils and charcoal. It is the thinnest, strongest known material, researchers say. In graphene, the carbon atoms are arranged like a chicken-wire fence in a layer so thin that is transparent, and an ounce would cover 28 football fields.

The team found that graphene, whether made directly on copper or nickel or transferred onto another metal, provides protection against corrosion.

Copper coated by growing a single layer of graphene through chemical vapor deposition (CVD) corroded at 14% the rate bare copper, and nickel coated by growing multiple layers of graphene corroded at 5% the rate of bare nickel.

A single layer of graphene provides the same corrosion protection as conventional organic coatings that are more than five times thicker. Graphene forms the ideal corrosion-inhibiting coatings, say the researchers, in applications where a thin coating is favorable, such as microelectronic components (e.g., interconnects, aircraft components and implantable devices). Research funding came from the National Science Foundation.

Vanderbilt University

www.vanderbilt.edu

Filed Under: Uncategorized