This article provides more detail to the Mitsubishi Sea Angel, a turbine with a hydraulic drive train.

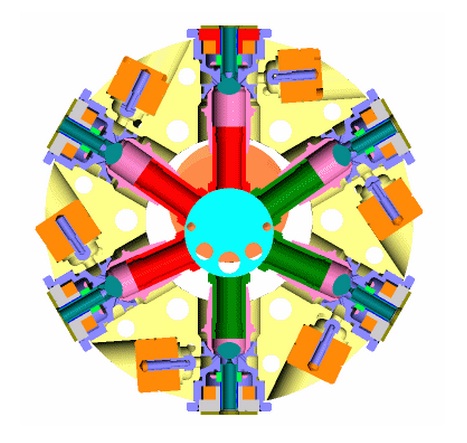

A low-speed Digital Displacement Pump (purple disk) provides fully-variable rotor torque, while two Digital Displacement Motors (red) provide constant-speed drives to standard synchronous generators.

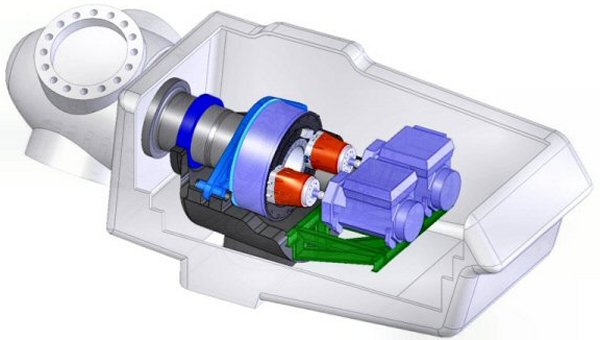

Mitsubishi Heavy Industries (MHI) has announced the start of test operations at Yokohama of a ‘large-scale wind power generation system that adopts a hydraulic drive train in place of the earlier gear-driven system. Engineers with Artemis Intelligent Power have the privilege of working with their Japanese colleagues in building the biggest yet, Digital Displacement transmission (DDT).

The tests are taking place within an existing MWT100 wind turbine in which the gearbox has been replaced by the DDT. The next step is to build a commercial 7-MW offshore wind turbine named SeaAngel.

The first SeaAngel is due for Scotland during 2013, and two more machines with floating foundations have been ordered by the Japanese government for operation off Fukushima.

Development work on the DDT for large offshore wind-turbines is supported in the UK by its Department for Business, Innovation and Skills, through the Technology Strategy Board. Earlier stages of development at Artemis were supported by Carbon Trust and by Department of Energy and Climate Change.

Mitsubishi work in Japan is supported by the Japanese government through New Energy and Industrial Technology Development Organization.

Artemis technology provides a new way to build variable-displacement hydraulic pumps and motors that have all of the strengths of traditional hydraulic machines but with huge gains in energy efficiency and controllability. Because machine behavior is directly controlled by fast-acting microprocessor-controlled solenoid-valves, the company came up with the phrase Digital Displacement.

The new hydraulics work this way

Rotating hydraulic pumps and motors usually contain multiple pistons and cylinders arranged in axial or radial configurations. At precise times, governed by the motion of its piston, each cylinder must be connected either to the low-pressure or the high-pressure side of the external system.

This critical process of flow-control, which is analogous to the ‘commutation’ of the rotors of simple electric machines, is traditionally performed by mechanically actuated valves or port-plates. Variable-displacement is commonly provided by a ‘swash-plate’ to vary the length of each working stroke.

Traditional machines have unrivalled power to weight ratios, legendary toughness, reliability and good efficiency when working at or near full power. However, due to high standing losses associated with conventional valve and swash-plate operation, they generally have poor efficiency when working at partial load. The problem and the difficulties of fast control by computer, has locked hydraulics out of many applications.

A new approach

While working on the development of an advanced variable-displacement hydraulic machine in the 1980s, the founders of Artemis Intelligent Power conceived of a new way to overcome these problems. To unlock the full potential of hydraulics, Artemis replaced the mechanical valves and swash-plates of conventional variable-displacement hydraulic machines with computer-controlled high-speed solenoid-valves. This opens new markets for hydraulics because Digital Displacement machines are efficient at all load levels and have super-fast response to computer control.

How Digital Displacement works

An animation on the company website (www.artemisip.com/our-technology) shows a single-bank from a Digital Displacement Pump (DDP) that is ‘idling’ at low-pressure. There are six piston-cylinder pairs in a radial configuration suitable for high-speed machines. The outer ‘small end’ of each cylinder can move around within the spherical cup of an active low-pressure valve to accommodate changing angles as the single-eccentric shaft rotates. The bluish-colored poppet of the low-pressure-valve at the outer end of each cylinder stays open all of the time. This means that, as they move inward toward the camshaft, the moving pistons suck oil in from the space around the machine – and as they move outward, they return the oil to the same low-pressure space. The pump is just ‘breathing’ and doing no useful work. However, this low-pressure idling consumes little energy and is one reason why Digital Displacement machines have unrivalled efficiency even when operating at fractions of rated power.

In contrast to the idling pump, a next animation shows the same bank of cylinders inside the same pump – but now all of the cylinders are ‘enabled’ once in every revolution. Watch the top piston as the animation runs. As it moves down to the center of the machine it draws in oil from around the machine through the open poppet of its low-pressure valve, the green phase of the animation. However, as the piston passes bottom-dead-centre you can just see the solenoid of its low-pressure valve flash red, forcing the low-pressure valve poppet to close and to stay closed for the remaining half-cycle.

At this stage the piston color changes to red, to show that the oil pressure increases from the low ‘boost’ value of a few bar up to the system pressure of perhaps 350 bar or more. Oil has low compressibility, so the pressure-rise in the cylinder is almost instantaneous. The high-pressure valve to the right of the low-pressure valve opens. You can just about see its purple poppet move to the right. In the case of a pump such as this, its high-pressure valve is a simple spring-loaded check-valve. As the piston moves toward top-dead-centre, oil is forced at high-pressure out through the open poppet of the high-pressure valve and into the external hydraulic system.

The solenoids are activated by Field Effect Transistors, which are in turn connected directly to the digital output of an embedded controller. This intimate marriage of mechanics, electronics, and software is a defining characteristic of Digital Displacement.

Instant response

The animations show the pump either fully idling or fully enabled. Of course, it usually operates somewhere in between, with each individual cylinder being enabled by the controller as its contribution is required to satisfy the changing needs of the external system or task. The keys to Digital Displacement are that these enabling decisions are made just-in-time to satisfy the instantaneous requirements of the external system and that idling cylinders consume little parasitic energy. This makes the machines responsive and efficient.

Other advantages

To the hydraulic designer, there are follow-on benefits from using active valves because mechanical layout is simplified. Valves can be placed around the perimeter where there is space for easier fluid breathing rather than around the centre of the machine. This helps reduce energy losses even more. Piston pads can be near the center of the machine where linear velocities are lower and shear losses therefore smaller.

The first small prototype Digital Displacement pump was built by Artemis in the 1990s. It has a nominal power rating of around 15 kW. Animations on the company website are based on this kind of machine. You can identify pistons and cylinders as well as low- and high-pressure valves and their components.

At top-dead-centre of pumping strokes, high-pressure oil is slightly compressed compared with its volume at low-pressure. In conventional pumps, most of this compression energy is lost when the low-pressure valve opens against residual cylinder pressure. This is the source of much of the high-frequency noise associated with hydraulic machines. In Digital Displacement machines, compression energy is naturally recovered because the low-pressure valves open only when the cylinders decompress naturally. The related and unprecedented reduction in noise made it possible to think of creating the Artemis Digital Displacement series-hybrid car transmission.

Multiple banks of cylinders can be packed along a common crankshaft, to create either a single large-capacity machine or a multiple-service machine with a number of independent hydraulic outputs.

Motors

Digital Displacement pumps, discussed above, incorporate active, solenoid-driven, low-pressure valves and passive, spring-loaded, high-pressure check-valves. To create the equivalent Digital Displacement motor, requires actively controlled valves.

Generally, it’s straightforward to make a Digital Displacement motor also function as a pump when required. Such combined-function machines are referred to as Digital Displacement Pump Motor (‘DDPM). A single or multi-bank DDPM can have some cylinders pumping into one function of an external task while others motor and recover energy from another task. In this way, complex control tasks, such as those found in off-road applications, can be addressed efficiently by a single physical machine without wasteful dumping of energy by pressure-relief valves.

Artemis Intelligent Power Ltd

www.artemisip.com

Filed Under: Components, Hydraulics, News, Turbines