Amar Pradhan, COO, Fluitec Wind, www.fluitecwind.com

Every day, people create 2.5 quintillion bytes of data — so much that IBM estimates that 90% of the data in the world today has been created in the last two years alone. This data comes from everywhere: sensors that gather climate information, posts to social media sites, digital pictures and videos, and purchase-transaction records to name a few. This is what IT people call big data. In the world of power generation, wind turbines are one of the most prolific data producers.

Wind turbines are machines in the sky that transmit power from one end and data from the other. These data streams have tremendous value if used correctly. With the impressive analytical tools built by the IT industry over the last few years, it is now possible to use these data streams to significantly reduce wind turbine O&M costs.

We are aware of the wind industry’s high operating costs due to the inherent variability in operational and environmental conditions. For instance, two similar turbines on the same farm may have significantly different production curves and failure modes as they encounter unique effects from wind gusts, humidity, construction, alignment, maintenance, and other factors. There is no one-size fits all solution.

Moreover, it has been shown that due to data noise and operational variability condition-monitoring paradigms using static critical levels and conventional analyses do not provide the required advanced warning abilities, or decrease O&M costs. This is the environment in which big-data can solve problems and identify solutions.

So how can wind-turbine operators implement enormously complex big-data tools, and what are the inputs and outputs?

Data mining

Many in the wind industry assume data mining and other big-data tools are simply advanced statistics: a sort of super regression, for those of you who can recall statistics class. In fact, they bear surprisingly little relation to one another: data mining methods have roughly one-fifth the error in identifying incumbent turbine failure. Data-mining methods focus on constructing feedback loops which lets algorithms identify relationships between highly interdependent attributes and continually modify themselves to reduce error in their output. Fluitec Wind, for example, has developed a patent pending, ensemble-learning method that runs wind-turbine data through more than 10 unique base algorithms with a meta-algorithm supervising the results to define a single least-error value. This method has been optimized for wind-turbine data and O&M reduction solutions.

Data inputs

Data which tracks genetic attributes – items such as equipment configuration, environment, historical activity, SCADA logs, up-tower maintenance logs, and weather–have been the most important to define equipment health and reliability. However, they do so with significant error bands or uncertainty. Diagnostic data inputs such as oil analysis and vibration are crucial to decreasing error bands.

The best analogy is to healthcare: given a patient’s age, income, lifestyle, historical illness, genetic predispositions, a doctor can estimate to a high degree what the patient is at risk of contracting. Diagnostic tests such as blood sampling, medical imaging, and various others lets a doctor more accurately identify the likelihood, timing, and risk mitigation options. Knowledge on how to parse diagnostic data is, of course, essential. In wind turbines, oil analysis data is the most regularly and widely produced diagnostic data stream (especially when compared to vibration). It is therefore the most valuable from a big-data standpoint.

Recent up-tower data collection devices will undoubtedly help augment future predictive abilities, but are not a pre-requisite to conduct significantly higher value analyses.

One challenge with any real world, human entered, data is “noise” and “dirt”. Dirt is essentially input errors and inconsistencies. Noise is inherent variability in sampling and testing across a global fleet. Both of these data quality issues can be solved elegantly with data-mining techniques. In most big-data tools, specifically ones able to use wind-turbine data, more than 50% of the work goes into converting raw data into a clean, usable state. Absence of such tools leads to the traditional “garbage in, garbage out” issues with current statistical analyses.

Another challenge to effective analysis is the need for large quantities of input data. Aggregating data globally is important in a fragmented industry such as wind energy, where the largest operators have less than 5% of the market with significant equipment permutations, and widely varied geographies. Analysis conducted by agnostic third parties with no product centric agenda may also be important to providing the most useful insight.

Data output

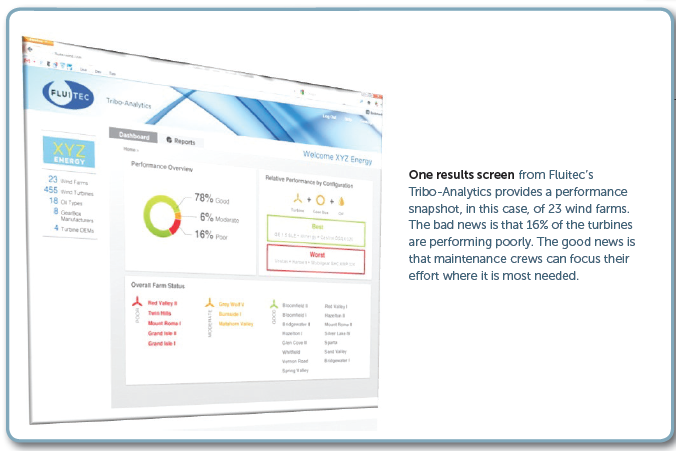

When used correctly, big-data tools provide a unique ability to predict events and behaviorally target solutions. As to predictive abilities, operators can identify, budget, and prioritize (with historical accuracies above 95%) which turbines need attention, when, and with what level of service. These predictions are tuned specifically for the turbine’s genetic, historical, and diagnostic attributes, resulting in unique critical levels and recommendations.

A deep body of work has been developed over the last few years with web-traffic data to target online advertising to consumers. The same capabilities can be adopted for wind turbine data to identify specific actions, products, and services that lead to extended life and increased reliability. This is especially useful for wind turbines where there are many quality 3rd party products that only benefit turbines of certain configurations or in certain environments. Identifying these turbines using conventional methods is neither easy, nor efficient. For example, an operator with 1,000 turbines spread over different geographies and equipment types may need a larger capacity desiccating breather in the gearbox within only a certain percentage of the fleet. Behavioral targeting identifies exactly which turbines will benefit, and to what extent, helping operators make high ROI decisions.

To increase profitability

The wind-energy industry is a cutting-edge space with high costs. Fortunately, it’s almost fully wired to transmit and record large amounts of data. These are ideal circumstances for advanced IT technologies that can decrease the cost of operations. Leaving these technologies solely to tasks such as placing real-estate ads on Facebook is a subpar use of a significant technical capability. It is good news that the wind industry is sitting on years of valuable data that can be quickly converted into actionable knowledge. Fluitec Wind has shown that correct use of data can decrease yearly operating costs onshore by more than 10% and offshore costs by more than 25%. These technologies and data sets decrease the cost of renewable energy. WPE

Filed Under: Gearboxes, Lubricants, O&M