Editor’s note: This is a significant release because excess wind generated power could store as electrolyzed hydrogen which would then be available as a fuel for a variety of uses, including use in fuel cells to regenerate electrical power.

The Hydrogen Air MEA is a 5-Layer Membrane Electrode Assembly with integrated Gas Diffusion Layers for use in hydrogen-air fuel cells.

FuelCellsEtc says it is known for its high quality, custom Membrane Electrode Assemblies (MEA) and produces any quantity of custom MEAs without a minimum order. The company provides MEA s and Catalyst Coated Membranes for electrolyzer systems, hydrogen air and hydrogen oxygen fuel cells, Direct Methanol Fuel Cells and, reversible systems (capable of serving either as an electrolyzer or as a fuel cell). The focus of this announcement is the company’s Hydrogen Air Membrane Electrode Assembly.

The MEA is a core component in all fuel cell technologies, converting the chemical energy from a fuel into electricity through a chemical reaction with oxygen or another oxidizing agent. A membrane-electrode assembly (MEA) consists of two electrodes (the anode and the cathode) with a thin layer of catalyst and a gas diffusion layer, each bonded to both sides of the membrane.

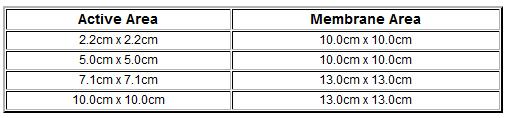

The Hydrogen Air MEA is a 5-Layer Membrane Electrode Assembly (MEA) with integrated Gas Diffusion Layers (GDL) for use in Hydrogen/Air Fuel Cells. It is one of the most economical and cost effective MEAs on the market with the following configurations: mid-range Platinum loadings (0.5 mg/cm²) on the anode and cathode sides, a 0.002″ proton exchange membrane (Nafion 212), and 410 micron thick carbon cloth gas diffusion layers (others available) on the anode and cathode sides. Custom sizes and configurations are available without minimum order quantities with typical lead times of 1 to 3 days, even for custom configurations. The table lists a few hydrogen-air MEA dimensions.

The table lists a few hydrogen-air MEA dimensions.

If you are having trouble figuring out how many membrane electrode assemblies are needed for a fuel cell, the company offers a Hydrogen Air Calculator that may help. All users have to do it take the IV curve of any MEA, choose an active area, operating point (current density) and required power output, and the calculator tells how many MEAs are needed, the voltage, and current of the fuel cell operating at that point.

The company also provides a Custom 5-Layer Membrane Electrode Assembly Creator to provide most any kind of MEA needed. It features:

• Any Shape, Size, Catalyst Loading, and Quantity

• Single Sided, 3-Layers, 5-Layers, 7-Layers, and more

• Consistent Expert Technical Assistance every step of the way

FuelCellsEtc

www.fuelcellsetc.com/store

Filed Under: News