This article comes from IDTechEx.and is authored by Dr Richard Collins, Technology Analyst at IDTechEx.

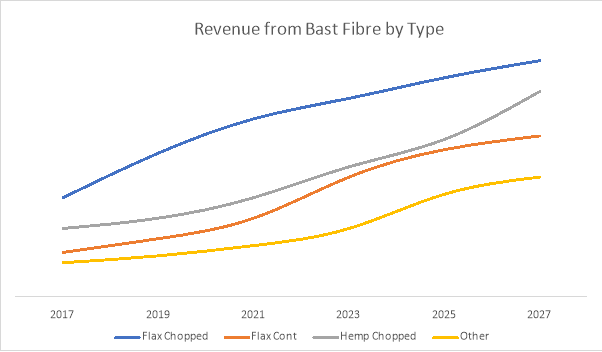

Fiber reinforced polymers (FRPs) are predominantly made of synthetic fibers, such as glass or carbon, and a petrochemically sourced thermosetting resin or thermoplastic matrix. However, natural fibers and resins are on the rise because of their beneficial properties, competitive cost, legislative drivers, and consumer preferences. IDTechEx forecasts the revenue for bast fibers used in composite parts to exceed $140 million by 2027, which would have been greater still if the supply could be grown fast enough to match the burgeoning demand.

Wood Fibers have been extensively used in composite materials for applications such as garden decking, but an emerging field of high-performance bast fibers are gaining interest. These bast fibers include flax, hemp and jute and are immediately attractive as they provide comparable or improved tensile strength and stiffness to that of E-glass fiber, as well as contain favorable vibration dampening and non-abrasive properties.

The cost of bast fibers is not significantly higher than that of glass fibers, particularly for the short/chopped variants, but as with all materials, there are a few notable downsides including high levels of moisture absorption, poor matrix adhesion, as well as the potential impact on the land. There are some key innovations for the Fiber-matrix interface that will stop bast Fiber composites from being held back, particularly surrounding the promising use of plasma treatment technologies. See a previous article for more about the other downsides of FRPs.

IDTechEx analysts identify these flax fibers used in a variety of parts. A car door interior (top left), an aircraft trolley (top center), automotive trunk floor (top right), flax cross-hatch for automotive interior part (bottom left), and a concept car with flax roof and bonnet (bottom right)

Profitable bast fibers also give the opportunity for farmers to diversify, and hemp is particularly beneficial as it can grow effectively on unfavorable land. Legislation is changing around growth restrictions of hemp in North America and this makes it more attractive and therefore IDTechEx forecasts the market to rise at a higher rate in the mid to long-term as a result.

10-year market forecast for bast fibers by different type. Source Composites 2017-2027: Innovations, Opportunities, Market Forecasts (www.IDTechEx.com/composites)

The main reason that bast Fibers and natural resins are being talked about so much is due to the sustainability advantages, as industries look to improve their Life Cycle Assessments (LCA). Although the natural Fibers are not biodegradable or reusable when embedded in synthetic resins, and many of the natural resins are also not biodegradable because of artificial catalysts used, they still deviate from (sometimes toxic) petrochemically sourced resin precursors.

The main commercial applications have been in the automotive sector and in sports equipment. The automotive sector makes good use of short bast Fibers for the interior of car doors (see top left photo below) to provide lightweight sound and vibration dampening. Ecotechnilin are the market leaders for short flax fiber products; they currently have a capacity for 6,000 to 7,000 tpa with plans to expand in the near-future. Their main market is automotive interiors, but they will be used for the trolleys on airplanes having demonstrated they can withstand 9G acceleration testing. Reflecting the demand in this industry, IDTechEx were also told that Ecotechnilin had to turn down a large order from IKEA, as meeting the required volumes would be a challenge.

For more see www.IDTechEx.com/composites and find out more about IDTechEx at www.IDTechEx.com.

Filed Under: Blades