Rhys Foster/ principal grid systems engineer/ Energy Solutions Group/ A123 Systems • www.a123systems.com

Storing excess power and then recalling it to stabilize the grid makes renewable energy sources, such as wind, more valuable. Sizing the battery, however, should be a team effort between grid and wind-farm operators, and storage system designers.

The wind industry has been a mixed blessing to transmission operators. For instance, as wind-farm outputs rise, the power grid shifts from predictable and dispatchable generation to one that is variable and non-dispatchable. Renewable sources also tend to be geographically concentrated and often isolated, creating transmission constraints.

In response, renewable-energy developers and grid operators are shaping strategies to meet these changes, including deploying grid scale, energy-storage systems as efficient solutions for smoothing the output of wind-power generators and to control fluctuations in the energy flowing onto the grid. By tapping stored reserves when the wind slows and recharging storage when it picks up, battery-energy-storage systems in particular can help control the rate at which wind power flow onto the power grid.

U.S. utilities are moving forward with large projects to showcase the viability of energy storage in batteries as ramp-management solutions. These will demonstrate that wind power and storage can deliver clean, reliable energy in complementary ways.

Before initiating a battery-based, energy-storage project, it is important that utilities and power producers work with the technology provider to determine an optimal size of a battery system to meet the requirements for a wind-ramping application.

Actual versus synthetic data

A sound approach to right-sizing a battery-based storage system begins with an evaluation of accurate historical data. Simulating the performance of the proposed system on real data –that taken from a renewable power source – allows for a detailed, time-dependent analysis, which has substantial advantages over statistical or stochastic methods. These are probabilistic statistical analyses, usually incorporating forms such as Monte Carlo simulations. Although stochastic methods allow considering synthetic data (from a computer model), care must be taken in this synthesis to capture the true nature of the data. Although static analyses often require less computation time than a time-domain analysis (particularly for large, or high temporal resolution, data sets), there are several advantages of the time-domain analysis.

First, the time-domain approach allows modeling a control system, which can gauge the effectiveness of a proposed algorithm, the system’s expected stability under a wide variety of simulated conditions along with the potential effect of equipment response times, measurement delays, and control parameters, such as gains, deadbands, and limits.

In addition, the time-domain approach allows real-time system modeling, which can help determine time-dependent thermal

effects as well as battery performance during all thermal and power-related conditions.

This technique also allows visualizing events which can be used to capture “edge” cases to determine the exact sequence of events that lead to customer-requirement violations and system boundary conditions, such as battery depletion, overcharge, over-current, and over-temperature.

The major challenge to using a full, time-dependent solution is the computational complexity – it requires computers to calculate the system response to millions of data points many times. These will determine optimal settings for a given set of customer requirements. Further, the overall model is only as good as the component models of which it is comprised, thereby requiring that technology providers have reliable dynamic models of their storage element and other key subsystems. As a result, not every energy storage provider willingly invests in the necessary infrastructure and internal model development required to adequately perform a time-domain analysis.

The outlined advantages make the approach far more effective in modeling a battery based, energy storage, so it is prudent for utilities to work with vendors able to conduct a detailed analysis. This will ensure they are deploying a system that meets all requirements, such as economic investment, physical footprint, and technical performance, and will continue to do so for the expected life of the project.

A battery sizing strategy

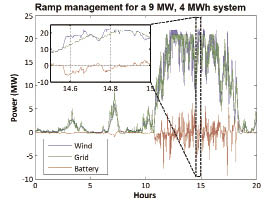

Ramp management refers to meeting power demand (grid) with supply (wind and battery). The inset shows more detail of a 30-min segment in a typical afternoon at a wind farm. For instance, as wind power surges at about 1460 hr, the battery (in red) absorbs some of the power.

Right-sizing a battery system is a detailed undertaking that involves several tasks. These start with an evaluation of historical data against the technical requirements put forth by the customer.

Understanding the application requirements is of particular importance to interpret its reporting requirements. Based on the system requirements, plotted representative operating data (line frequency, voltage, and real power are typical) can reveal aberrations such as missing data and uncharacteristic jumps. Because line conditions change frequently, unusual stability would also be suspect. It is important to verify that a sample rate of data along with power demand supports the update rate of the system requirements, and that the data set is representative of extremes as well as providing an overall average (which may be separate data sets).

When aggregating the output of multiple turbines, additional “averaging” occurs that reduces the volatility often seen from a single turbine. The primary reason for this usually is the spatial diversity of the wind speed seen by individual turbines. This diversification can be taken into account when matching data to system requirements.

After collecting the data, a statistical analysis can be performed to check distributions such as frequency of errors, ramp rates, or power pulse durations, which should provide at least one bound to the solution set. For example, the Cumulative frequency distribution of ramps graph shows the two-second, one-minute, and three-minute ramp rates as observed at a U.S. wind farm during a single month. The graph shows a logical progression of increasing variance with increasing time frame, which can be used to extrapolate a lower-bound power requirement.

This statistical analysis allows creating a more accurate time-domain matrix of power and energy-system sizes. The Ramp management graph shows historical data and a few key analysis outputs during a typical day at a U.S. wind farm, with a candidate system performing wind-ramp management to meet project requirements, such as power and response time.

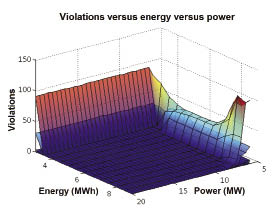

A next step is to assess the sensitivity of the system’s requirements to changes in power or energy. Of particular importance are zero crossings for inviolable requirements, changes in curvature for less stringent requirements, and relative costs of energy versus power. Avoiding areas of steep sensitivity provides additional margin to account for changes in input data, delays in control response, and impacts of aging. The Violations versus energy graph is a theoretical surface plot of violations at given power (MW) and energy (MWh) intersections during the course of a year. In this case, the zero crossing occurs at about 9MW, 4MWh. The definition of a “violation” depends on customer or regulator requirements. In the case here, a violation is recorded when the ramp-rate (rate of change in real power) exceeds pre-defined limits.

After generating a surface plot of violations, it is prudent to consider irregularities in the analysis that may impact system size. For example, if a particular time in a 24-hr period exhibited an abnormally high number of violations, the energy-storage system would be sized to compensate. Another factor to consider when refining the analysis is the availability of practical increments of storage and power conversion components. If a particular energy-storage unit requires significant over-sizing to account for rare anomalies in the number of observed violations, it may be inefficient and therefore necessary to evaluate more modular and scalable solutions.

The surface plot tells where violations will occur – at the performance limits of a proposed power storage system. Plots of this sort are used to better gauge the size requirements for a storage system.

Another factor to consider is the effect of aging on the system based on the simulated operating environment, which can also impact maintenance requirements. In the case of lithium ion batteries, cells inherently lose some capacity and exhibit increased impedance over time, which must be incorporated into the analysis to ensure the system continues to meet its requirements throughout its operational life.

Finally, considering site-integration issues, accessibility, maintenance schedule, concurrent-use requirements, and input variability all contribute to developing a more accurate proposal for the initial site layout. It is important to ensure an expansion capacity that meets service-life requirements and possible changes in data volatility or requirements.

More renewable energy to come

The penetration of renewable energy sources continues to increase. AWEA reports that the U.S. has surpassed 50,000 MW of wind generated energy with more than 4,700 MW added in 2012 alone. This also increases the demand for grid-energy storage.

In addition to a theoretical understanding of how energy storage can complement wind power, it is important to understand the practicalities of evaluating, selecting, and deploying an energy-storage solution. Accurate and detailed data based on time-dependent analysis can provide a strong understanding of the operational requirements of a storage system.

This, in turn, allows a more accurate right-sizing of a solution that can have significant impact on the value of the system, particularly in a return-on-investment. As such, it is critical to conduct a thorough analysis of information to bridge the gap from raw data to real answers regarding the size and capabilities needed for an energy storage system. WPE

Filed Under: Energy storage, Featured, News

Dear genie81:

Since turbines connect to the grid, they contribute when the wind is blowing. When it is not, coal fired plants can power on. Because they are on the grid, wind provides backup for coal plants when they go offline. The PPAs I’m aware of sell wind power to utilities at 4 to 5 cents/kWh. Good wind forecasts let wind plant operators predict when they can produce, thereby avoiding the backup power costs. My figures report that gas and wind are the least expensive and cleanest power sources available, and they work well together. That’s the future and that is good news for all of us.

Will this stop turbines using backup 24/7 from coal or gas? Will it stop receiving RECs and as well with backup to the cost per Mw hour of $100-$120? While as is $60 per Mw hour and coal $40?