Applying artificial intelligence (AI) to wind-turbine data is becoming more prevalent and there is a growing number of use cases for the technology. Many of these cases involve wind-turbine O&M practices and can result in increased efficiency, better spare-parts forecasting, reduced downtime, and lower unplanned maintenance costs.

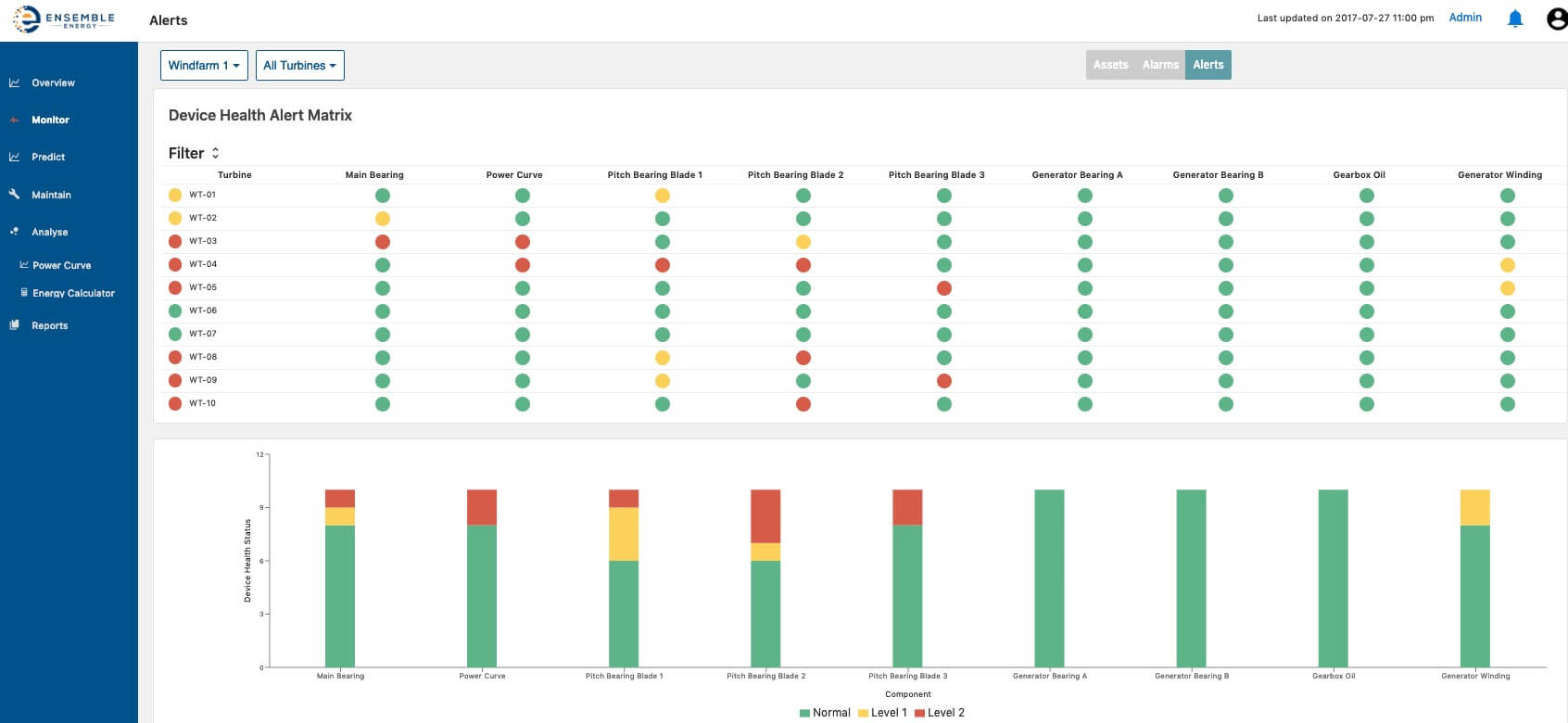

Ensemble Energy’s Energy.ML platform uses advanced machine learning algorithms to predict and prevent failures. Learn more here.

“The best definition of artificial intelligence is that it is set of methods or algorithms that use a large amount of data to learn rules or patterns, and continuously improves with additional data,” shares Rob Budny, Chief Reliability Officer at Ensemble Energy. He says most AI solutions are cloud-based, directing notifications to a dashboard or email, and many can work with a work-flow management system.

The sources from which AI can pull information may include:

- SCADA data (mean, minimum, maximum, and standard deviations),

- Maintenance data (component replacement dates, lubrication events, etc.),

- Failure histories

- Firmware updates

- CMS data (if available)

These data sources are then used to create models of normal turbine behavior, which serve to quickly identify abnormalities and notify the wind-farm operator.

“The models monitor a turbine 24 hours a day, seven days a week, and relieve human operators of the tedious task of sifting through extremely large data sets in search of relevant insights,” explains Budny.

He says one of the best examples of AI use cases is automated detection of yaw misalignment, which, if left undetected leads to lost energy production and increased loads on the turbine. Other examples include pitch-bearing, generator stator insulation, and transformer failure prediction, as well as detection of poor bearing lubrication conditions.

“Our AI platform continually monitors wind-turbine operation in the background, so it needs no operator input,” he says. “Be sure to look for a system that is supported by wind industry domain experts, as the combination of data science expertise and wind industry expertise leads to the best outcomes.”

Forecasting is another feature of certain AI systems, adds Budny. “Many types of forecasts are possible, including power production, availability, component over-temperature events, spare parts needs, and other such use cases. Having such increased visibility provides tremendous benefits to wind-turbine operators.”

Filed Under: News, O&M, Software